Transition metal selenide-carbon composite material, preparation method and application thereof

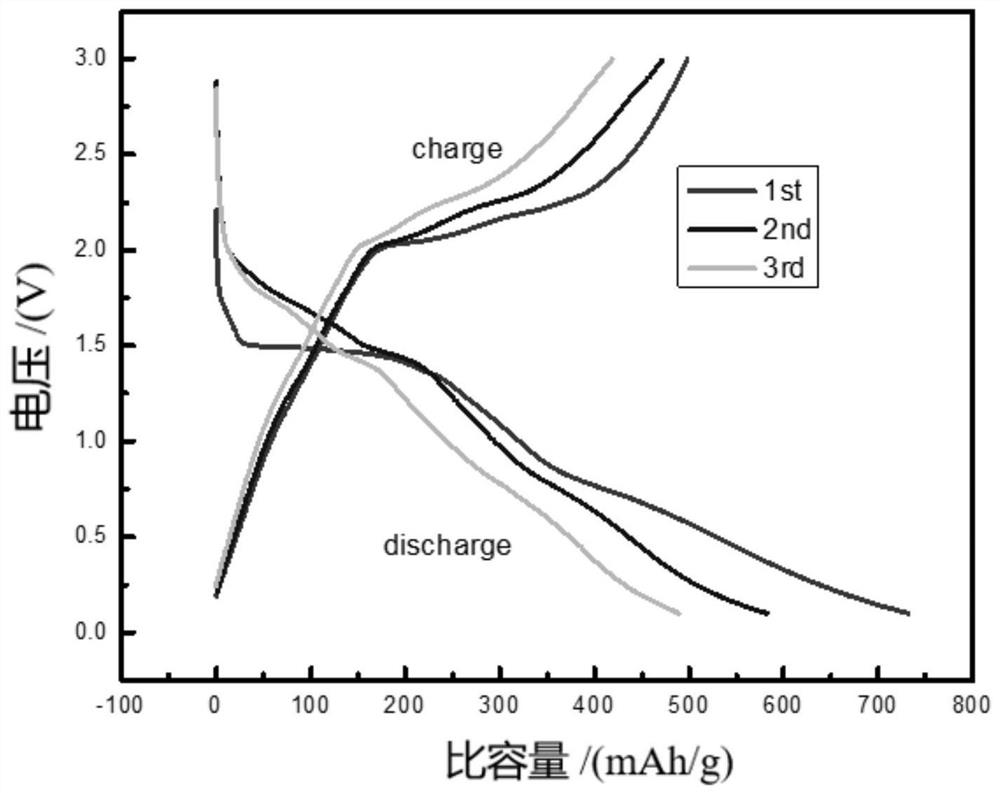

A technology of carbon composite materials and transition metals, applied in the direction of metal selenide/telluride, chemical instruments and methods, binary selenium/tellurium compounds, etc., can solve the problems of rapid volume expansion and poor electrochemical performance, and achieve structural Effects of optimization, improved conductivity, and broad research fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method of a transition metal selenide-carbon composite material, comprising the steps of:

[0029] 1) Preparation of cobalt selenide precursor: Dissolve cobalt source and carbon source in a mixed solution of deionized water, methanol and ethylene glycol according to a certain ratio, stir evenly, centrifuge, separate and dry, and dry the dried product at high temperature Calcination to obtain Co-MOF, an organometallic framework structure cobalt selenide precursor containing cobalt.

[0030] Wherein, the cobalt source is at least one of cobalt acetate, cobalt nitrate and cobalt sulfate, and the total amount is between 0.01-0.02 mol. The carbon source is at least one of 1,3,5-trisenetricarboxylic acid, polyvinylpyrrolidone (PVP), sucrose, and ascorbic acid, and the added amount of the carbon source is 6-12wt% of the total mass of the cobalt source. In the mixed solution, the volume ratio of deionized water, methanol and ethylene glycol is 30-60:100-200:100-2...

Embodiment 1

[0034] Weigh 1.405g of cobalt sulfate, 1.455g of cobalt nitrate, 2.49g of cobalt acetate, and 0.5g of melamine with a balance. Move it into a beaker with a volume of 500mL, then add 160mL of deionized water, 70mL of ethylene glycol and 70mL of methanol, and stir magnetically for 8h at a speed of 200r / min. Then the product was left to stand, and the supernatant liquid was removed, washed with deionized water for 3 times with a centrifuge at a speed of 7500 r / min, and dried in an environment of 80°C.

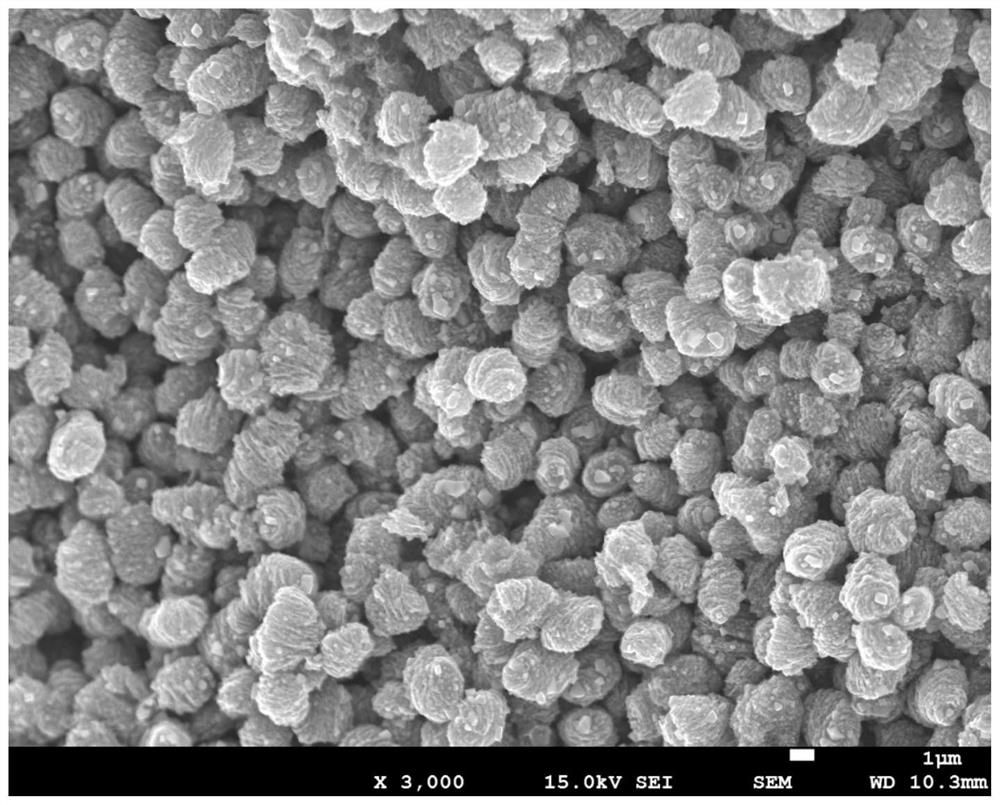

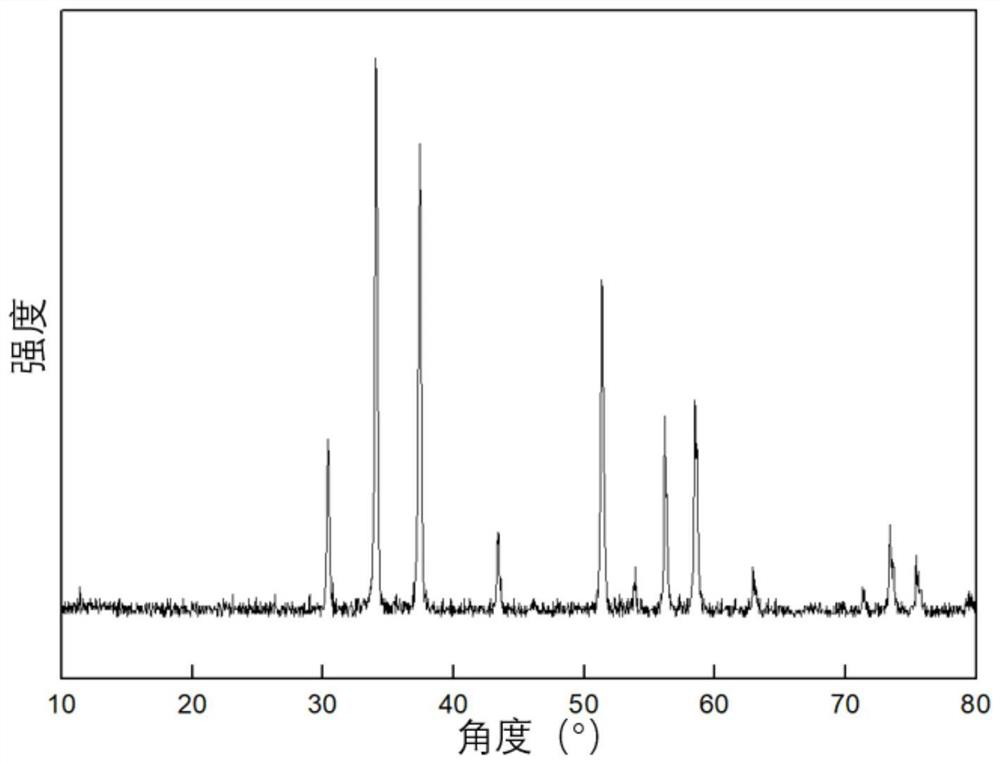

[0035] The above product was placed in a corundum ark, in an argon flow at a flow rate of 80mL / min, at 650°C, the heating rate was set to 2°C / min, after calcination at high temperature for 6 hours, it was slowly lowered to room temperature with furnace cooling, and the cobalt selenide precursor was obtained Bulk Co-MOFs. Weigh 120mg of Co-MOF and place it on one side of the corundum ark, and place 400mg of selenium powder on the other side. In an argon flow with a flow rate of 3...

Embodiment 2

[0039]Weigh 1.405g of cobalt sulfate, 2.49g of cobalt acetate, and 0.35g of 2-methylimidazole with a balance. Move it into a beaker with a volume of 500mL, then add 200mL of deionized water, 50mL of ethylene glycol and 50mL of methanol, and stir magnetically for 10h at a speed of 180r / min. Then the product was left to stand, and the supernatant liquid was removed, washed with deionized water for 3 times with a centrifuge at a speed of 7500 r / min, and dried in an environment of 80°C.

[0040] Put the above product in a corundum ark, in an argon flow at a flow rate of 100mL / min, set the heating rate at 2°C / min at 700°C, and after calcination at high temperature for 6 hours, slowly cool down to room temperature with furnace cooling to obtain a cobalt selenide precursor Bulk Co-MOFs. Weigh 150mg of Co-MOF and place it on one side of the corundum ark, and place 450mg of selenium powder on the other side. In an argon flow with a flow rate of 30 mL / min, the heating rate was set at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com