A kind of cyanuric chloride derivative and its preparation method and application

A technology of polycyanuric chloride derivatives and cyanuric chloride is applied in the preparation of sugar derivatives, sugar derivatives, sugar derivatives, etc., which can solve the problems of inability to meet the needs of higher shrinkage temperature of leather, and improve heat resistance. The effect of increasing the shrinkage temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention provides a method for preparing cyanuric chloride derivatives described in the above technical scheme, comprising: mixing cyanuric chloride, water, an emulsifier, a glucosamine compound and an alkali, and performing a substitution reaction to obtain derivatives of cyanuric chloride matter; the temperature of the substitution reaction is 0-5°C.

[0027] The present invention does not have special regulation to the source of described cyanuric chloride, adopts conventional commercially available product to get final product.

[0028] In the present invention, the water is preferably deionized water. The present invention selects deionized water as the solvent used in the reaction, which can avoid the adverse effects of impurities in the water on the reaction, and further improve the yield of the product.

[0029] In the present invention, the glucosamine compound preferably includes glucosamine hydrochloride and / or glucosamine sulfate. In the prese...

Embodiment 1

[0052] Example 1

[0053] A kind of cyanuric chloride derivative, its chemical structural formula is:

[0054]

[0055] The synthetic steps of cyanuric chloride derivative tanning agent are as follows:

[0056] (1) Add 72g of deionized water and 16.7g of cyanuric chloride to a four-neck flask, and add emulsifier AEO-90.6g, keep the temperature at 2°C, and stir evenly;

[0057] (2) keep the temperature constant, add 9.5g glucosamine hydrochloride to the above system, slowly add 18.5g of sodium hydroxide solution with a mass concentration of 20%, adjust the pH of the system, make the pH stable at 6.0, and continue the reaction for 4.5h, The resulting milky white tanning agent dispersion containing cyanuric chloride derivatives (the mass content of cyanuric chloride derivatives in the dispersion is about 15.4%) is obtained, and the dispersion is purified to obtain cyanuric chloride derivatives.

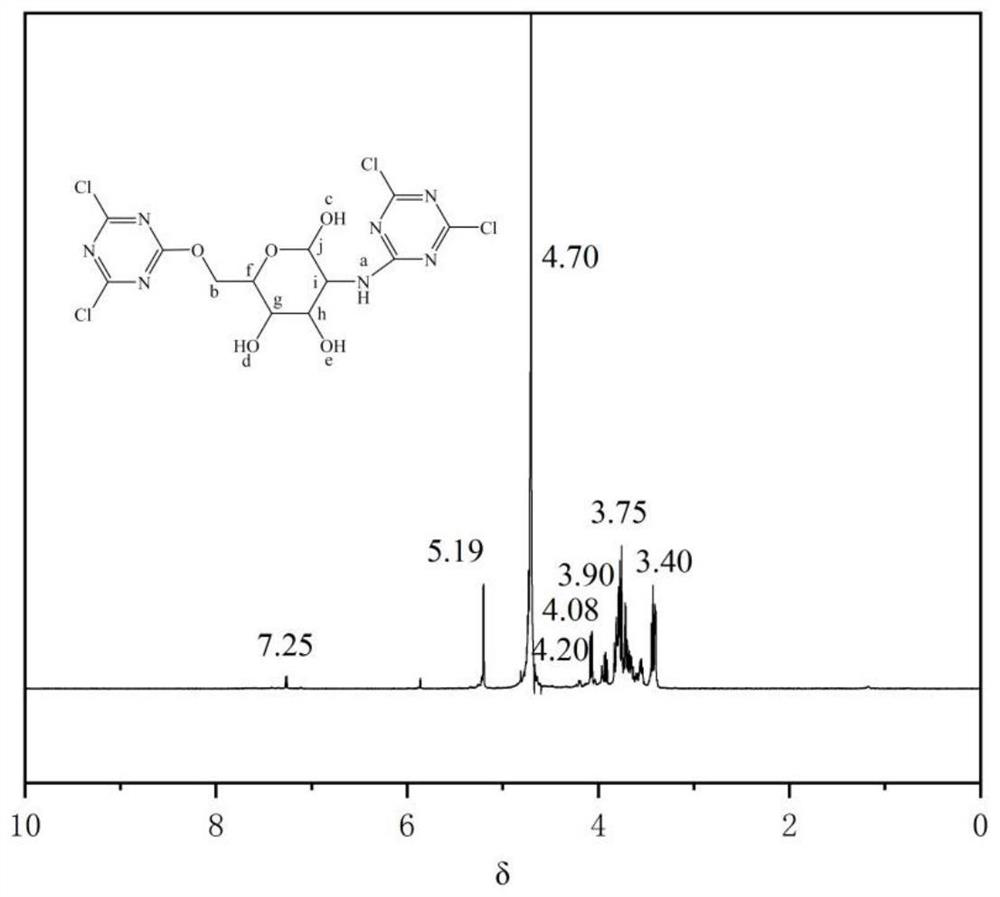

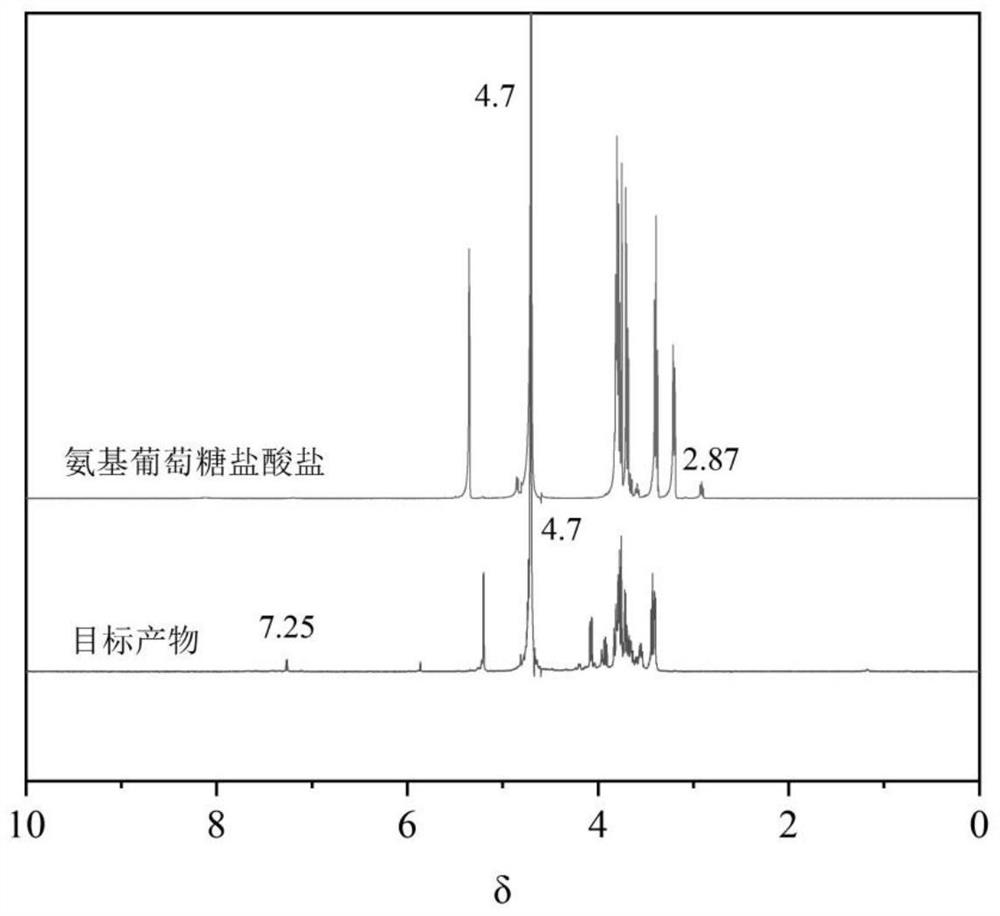

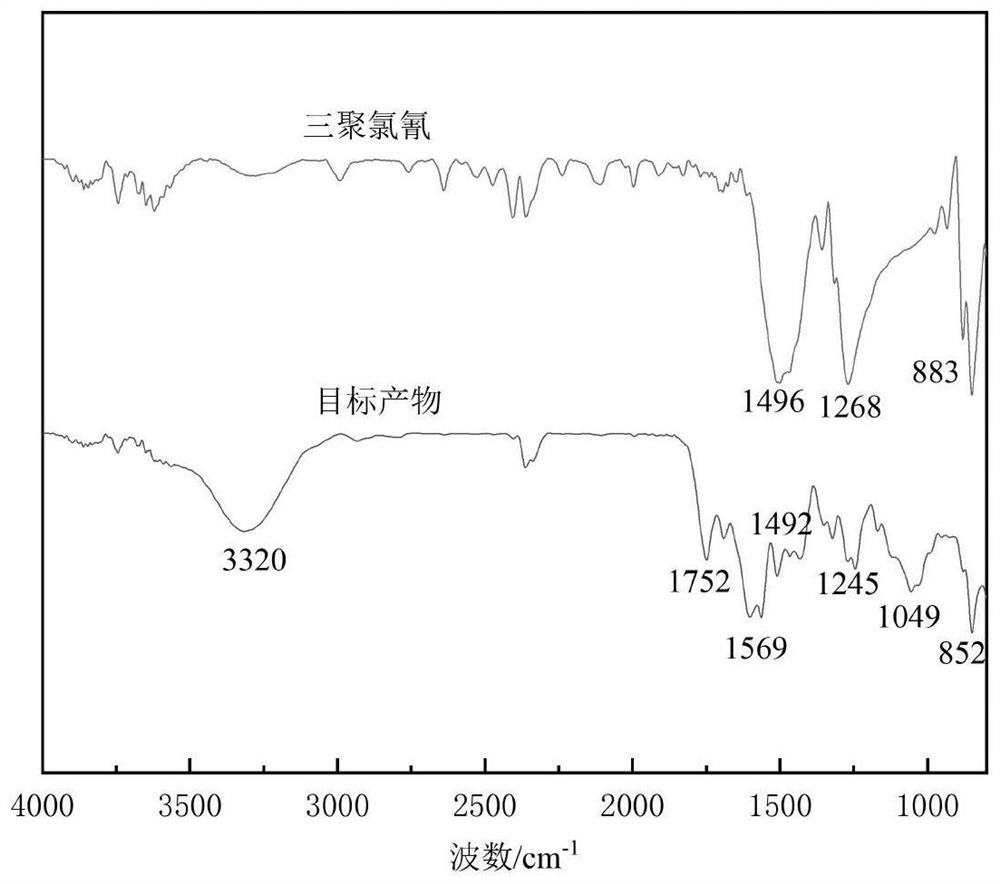

[0058] The NMR characterization hydrogen spectrogram of the cyanuric chloride d...

Embodiment 2

[0068] The chemical structural formula of cyanuric chloride derivative is the same as embodiment 1, and the main difference of preparation process is: change glucosamine hydrochloride into glucosamine sulfate.

[0069] The synthetic steps of cyanuric chloride derivative tanning agent are as follows:

[0070] (1) Add 68.5g of deionized water and 22g of cyanuric chloride into a four-necked flask, and add emulsifier AEO-71.0g, keep the temperature at 4°C, and stir evenly;

[0071] (II) Keep the temperature constant, add 13g of glucosamine sulfate to the above system, and slowly add 60g of sodium carbonate solution with a mass concentration of 12% to adjust the pH of the system to stabilize the pH at 6.8, and continue to react for 5.5h. The milky white tanning agent dispersion containing cyanuric chloride derivatives (the mass content of cyanuric chloride derivatives in the dispersion is about 15.2%) is purified to obtain cyanuric chloride derivatives.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com