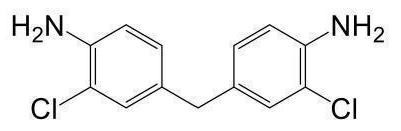

A kind of lignin-based polyurethane chain extender and its preparation method and application

A lignin-based, polyurethane technology, applied in the direction of biological raw materials, can solve problems such as browning, and achieve the effects of simple operation, avoiding the potential risk of cancer, high reaction selectivity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

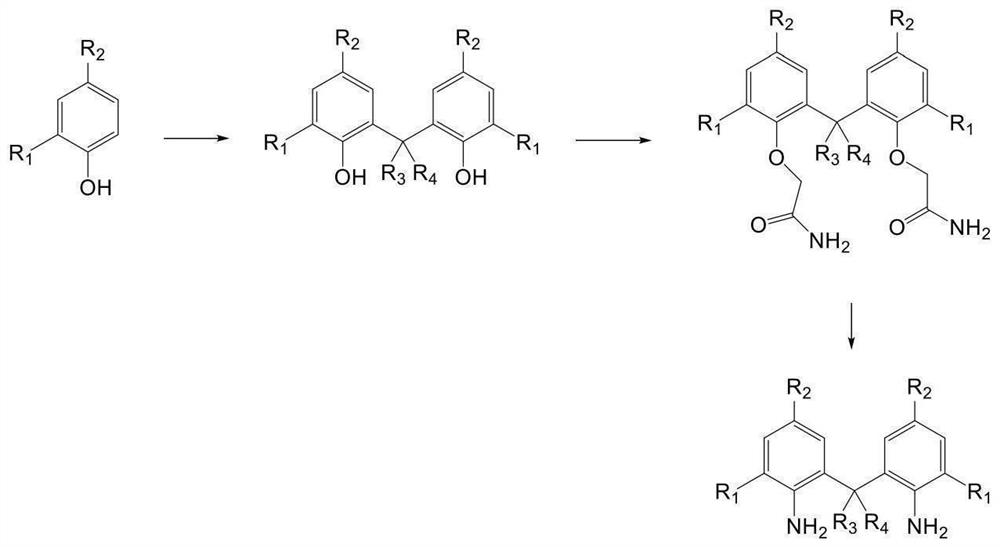

Method used

Image

Examples

Embodiment 1

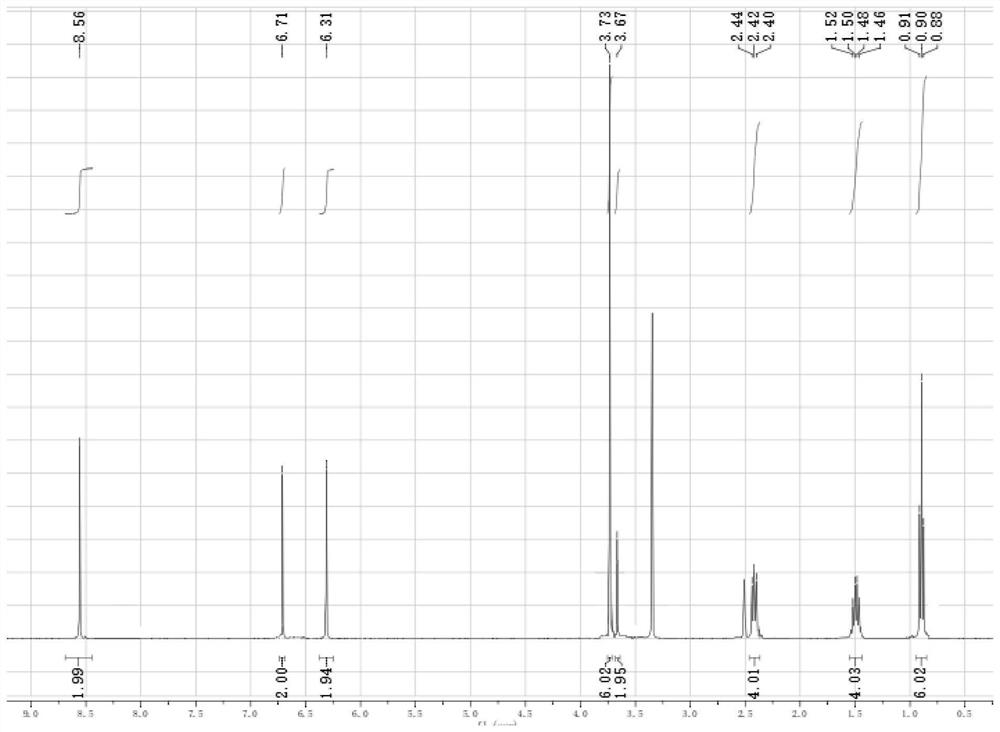

[0070]

[0071] IIIA 2,2’-Methylene(4-Methylphenol)

[0072] Accurately weigh 4-methylphenol (21.6g, 0.2mol), 40% formaldehyde solution (9.0g, 0.12mol) and p-toluenesulfonic acid (1.72g, 0.01mol) in a pressure bottle, and heat it in a water bath at 60°C Stir for 30 minutes, dilute with ethyl acetate after the reaction, extract with water and ethyl acetate, dry over anhydrous magnesium sulfate and concentrate the organic phase to obtain a viscous oily liquid (compound IIIA) with a yield of 80.3%. MSI-MS: 229.3[M+H] + .

[0073] IVA 2,2'-((methylene(4-methyl-2,1-phenyl))bis((oxygen))bisacetamide

[0074] Accurately weigh IIIA (11.4g, 0.05mol), chloroacetamide (5.8g, 0.0625mol), anhydrous potassium carbonate (15.5g, 0.1125mol), potassium iodide (0.83g, 0.005mol) in a 2L round bottom flask, Add 1.25L of acetone, stir at 60°C for 6h, filter after the reaction, spin the filtrate to dryness, extract with water and ethyl acetate, dry over anhydrous magnesium sulfate and concentr...

Embodiment 2

[0078]

[0079] 2A 6,6'-Methylene(2,4-Dimethylphenol)

[0080] Referring to the synthesis method of IIIA, 2,4-dimethylphenol was used instead of 4-methylphenol, and the yield reached 80.5%. MSI-MS: 257.4[M+H] + .

[0081] 2B 2,2'-((methylene(4,6-dimethyl-2,1-phenyl))bis((oxygen))bisacetamide

[0082] Referring to the synthetic method of IVA, the yield reaches 98.9%. MSI-MS: 371.5[M+H] + .

[0083] I-2 6,6'-Methylene(2,4-Dimethylaniline)

[0084] Referring to the synthesis method of I-1, the yield is 98.4%. MSI-MS: 255.4[M+H] + .

Embodiment 3

[0086]

[0087] 3A 6,6'-Methylene (2-methoxy-4-methylphenol)

[0088] Referring to the synthesis method of IIIA, 4-methyl-2-methoxyphenol was used instead of 4-methylphenol, and the yield reached 79.2%. MSI-MS: 289.3[M+H] + .

[0089] 3B 2,2'-((methylene(6-methoxy-4-methyl-2,1-phenyl))bis((oxygen))bisacetamide

[0090] Referring to the synthetic method of IVA, the yield reaches 96.4%. MSI-MS: 403.4[M+H] + .

[0091] I-3 6,6'-methylene (2-methoxy-4-methylaniline)

[0092] Referring to the synthesis method of I-1, the yield is 97.6%. MSI-MS: 287.3[M+H] + .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com