Treatment method for prolonging fatigue life of titanium alloy by using pulsed magnetic field treatment

A pulsed magnetic field and fatigue life technology, applied in the direction of improving energy efficiency, process efficiency, additive manufacturing, etc., can solve the problems of inability to eliminate internal defects of materials, difficult to effectively control the reinforcement layer, and time-consuming, etc., to improve fatigue performance. , The effect of improving residual stress and short treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

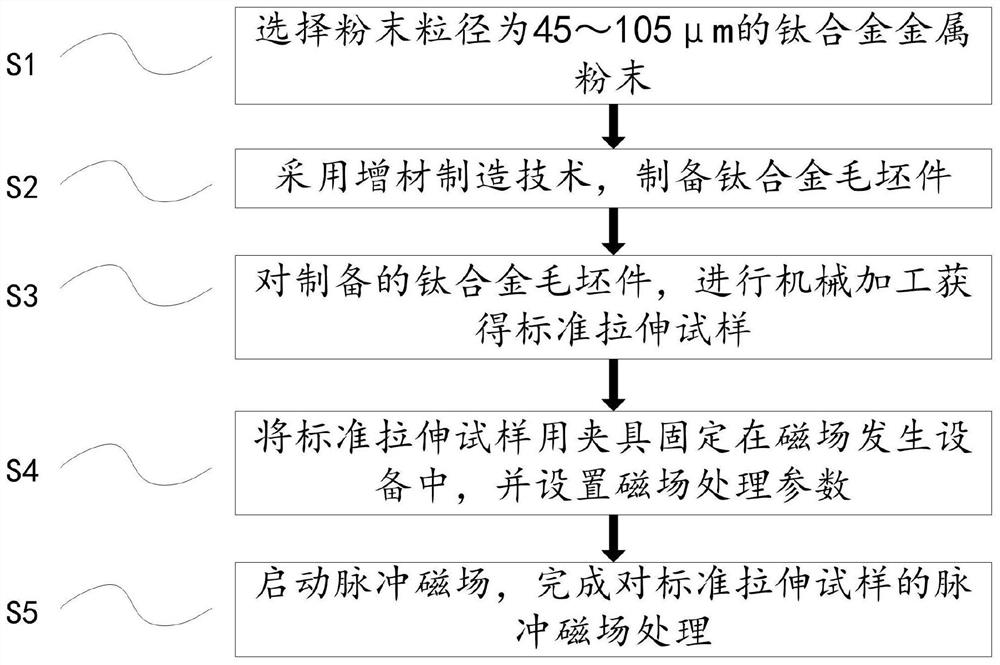

[0030] like figure 1 Shown are the flow steps of the entire processing method. First, for the preparation of titanium alloy samples, select the appropriate TC4 titanium alloy powder according to GB / T3620.1-2016, the powder particle size is 45-105μm, and its main components are titanium, aluminum and vanadium. Selective laser melting method (SLM ) to obtain titanium alloy blanks, according to GB / T 228.1-2010, mechanically process titanium alloy blanks to obtain standard tensile samples. It should be noted that the purpose of the standard testing samples used here is to be accurate and standard. , Reliably evaluate the performance of additively manufactured titanium alloy parts before and after pulsed magnetic field treatment. It does not mean that the effect of pulsed magnetic field treatment is only achieved in the case of standard samples, and can be achieved for titanium alloy parts prepared by additive manufacturing. The expected effect of the process.

[0031] Prepare me...

Embodiment 2

[0040] like figure 1 Shown are the flow steps of the entire processing method. First of all, for the preparation of titanium alloy parts, select the appropriate TC4 titanium alloy powder according to GB / T3620.1-2016, the powder particle size is 45-105μm, and its main components are titanium, aluminum and vanadium, and the selective laser melting method (SLM) is used. The titanium alloy parts blanks are prepared, and the parts for testing are prepared according to a certain type of titanium alloy bone plate. The schematic diagram of the titanium alloy bone plate is as follows Figure 5shown. According to the use requirements in practical applications, and to achieve good treatment effect and reliable performance improvement, the titanium alloy bone plate blank is first subjected to plasma polishing treatment, and then pulsed magnetic field treatment. It should be noted that the bone plate product used here belongs to a relatively common application product in practical applic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com