Black phosphorus thin film reaction device, black phosphorus thin film preparation method

A reaction device and thin film technology, applied in the field of two-dimensional materials, can solve the problems of high pressure, low crystal quality, and difficulty in controlling nucleation points, and achieve the effect of inhibiting the formation of nucleation points and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] According to a method for preparing a black phosphorus film according to a preferred embodiment of the present invention, the method includes:

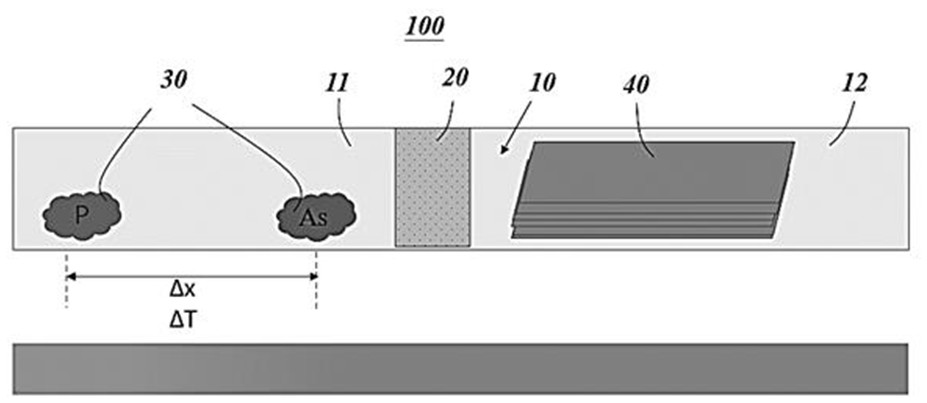

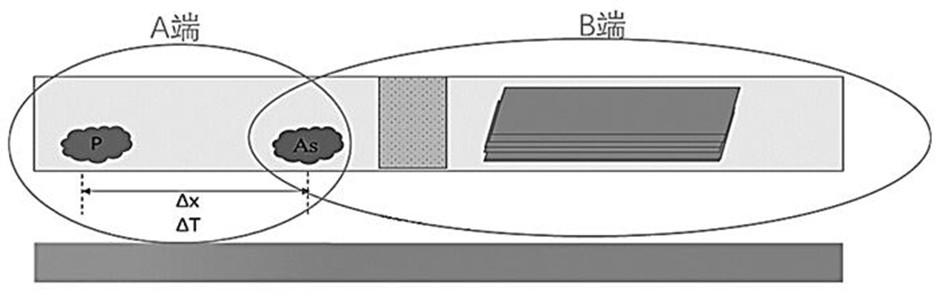

[0047] s1, provide figure 1 The black phosphorus thin film reaction device 100;

[0048] s2, placing the reactant 30 and the growth substrate 40 in the first reaction chamber 11 and the second reaction chamber 12, respectively, where the reactant 30 at least includes a phosphorus source and a mineralizer;

[0049] Heating causes the phosphorus-containing gas to enter the second reaction chamber 12 from the first reaction chamber 11 , and forms a black phosphorus film on the surface of the growth substrate 40 .

[0050]In some embodiments, the reactant further includes an arsenic source, the phosphorus source and the arsenic source are located at different positions in the first reaction chamber, and the temperature at the position of the arsenic source is controlled to be greater than the temperature at the position of the pho...

Embodiment 1

[0063] Example 1: Preparation of Black Phosphorus Single Crystal Thin Film

[0064] Preparation of reaction apparatus and raw materials:

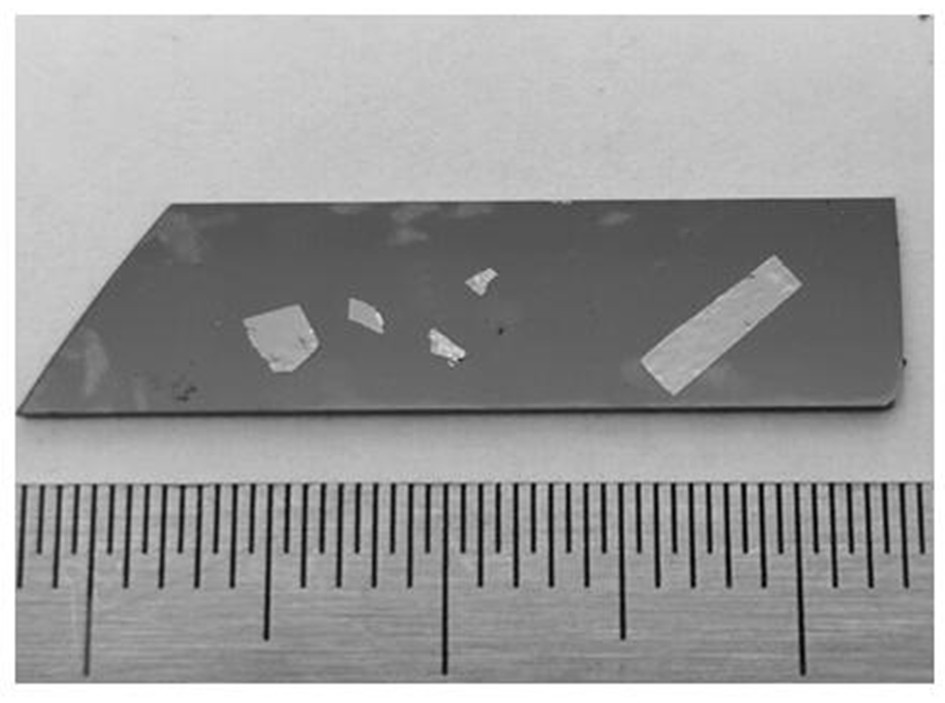

[0065] Provide 5 pieces of Si / SiO evaporated with 5nm-150nm thickness of Au metal film 2 sheet as a substrate for thin film growth. And provide red phosphorus, tin tetraiodide and tin particles as raw materials, the quality of these raw materials are 50mg, 5mg and 10mg respectively.

[0066] supply figure 1 The black phosphorus thin film reaction device shown uses a straight quartz tube as the reaction chamber. In the middle of the reaction chamber, there is a columnar buffer section filled with silicon oxide particles. This section divides the reaction chamber into two parts that communicate with each other through the silicon oxide particles. The raw material is placed in one section of the reaction chamber, and the silicon wafers coated with gold layer are stacked and placed in the other section of the reaction chamber.

[0067] Grow...

Embodiment 2

[0069] Example 2: Preparation of Black Phosphorus Single Crystal Thin Film

[0070] Preparation of reaction apparatus and raw materials:

[0071] Provide 4 pieces of Si / SiO deposited with 5nm-150nm thickness gold film 2 sheet as a substrate for thin film growth. And provide red phosphorus, iodine and tin particles as raw materials, the mass of these raw materials are 150mg, 5mg and 50mg respectively.

[0072] supply figure 1 The black phosphorus thin film reaction device shown uses a straight quartz tube as the reaction chamber. There is a quartz column in the middle of the reaction chamber, and a capillary channel with a diameter of 0.3 mm exists in the quartz column. This section of quartz column divides the reaction chamber into each other and passes through each other. The two connected sections of the capillary channel, the raw material is placed in one section of the reaction chamber, and the silicon wafers plated with gold layer are stacked and placed in the other se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com