Copper-based surface-enhanced Raman scattering substrate as well as preparation method and application thereof

A Raman scattering-based, surface-enhancing technology, applied in Raman scattering, sputtering plating, ion implantation plating, etc., can solve the problems of general enhancement effect, limited application, inconvenient storage, etc., and achieve enhanced enhancement effect , storage, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for preparing a copper-based surface-enhanced Raman scattering substrate provided in an optional embodiment may include the following steps:

[0029] In step S1, the metal copper foil is coated with an aluminum oxide layer of a certain thickness by atomic layer deposition. Wherein, the temperature is 80° C. to 200° C., and the coating can be successful and the coating effect is better at this temperature. For example, the temperature can be set to 150° C. and the like. The coating thickness of aluminum oxide is 4nm-12nm, and the corresponding number of coating cycles is 40-120 cycles; more preferably, the number of coating cycles is 60-120 cycles, and the corresponding coating thickness of aluminum oxide is 6nm ~ 12nm. For the thickness of the metal copper foil, the inventor has found through many experiments that wrinkles are easy to occur when the thickness is less than 20 microns, and the cost will increase when the thickness is greater than 80 microns, so ...

Embodiment 1

[0034] Embodiment 1 (not coated aluminum oxide)

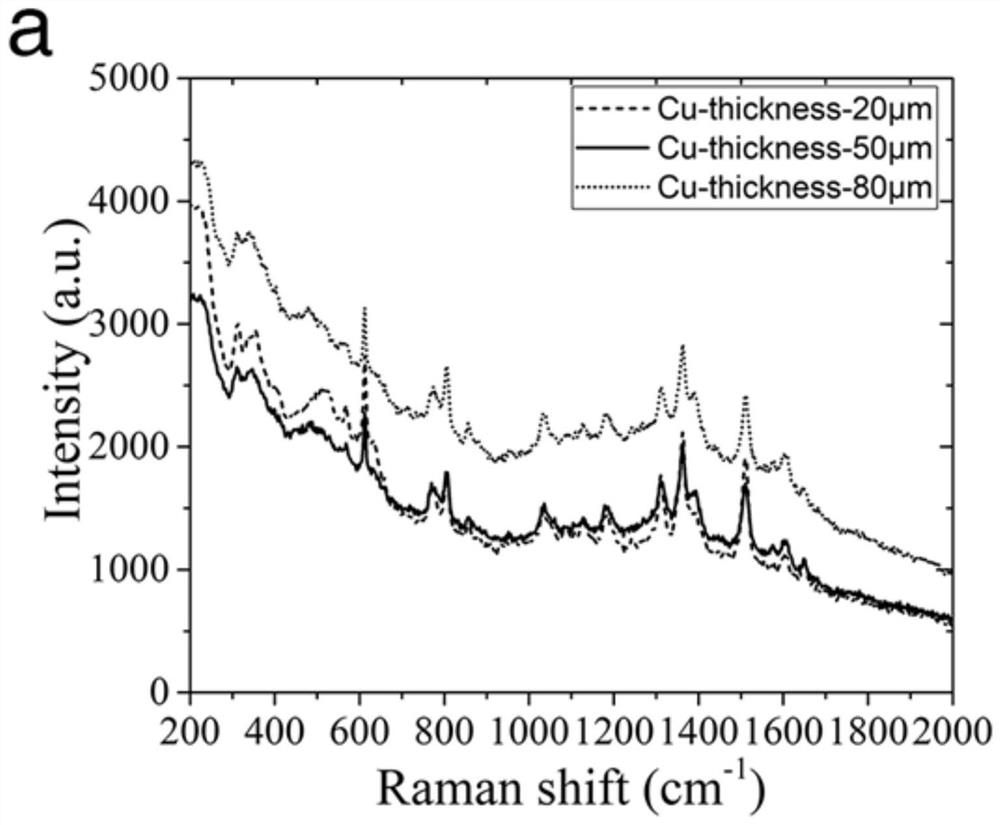

[0035] 1. Take copper foils with a thickness of 20μm, 50μm and 80μm respectively, and clean them;

[0036] 2. At room temperature, using high-purity silver as the evaporation target, pump the reaction chamber of the electron beam evaporation deposition coating machine to 5×10 -5 Pa high vacuum;

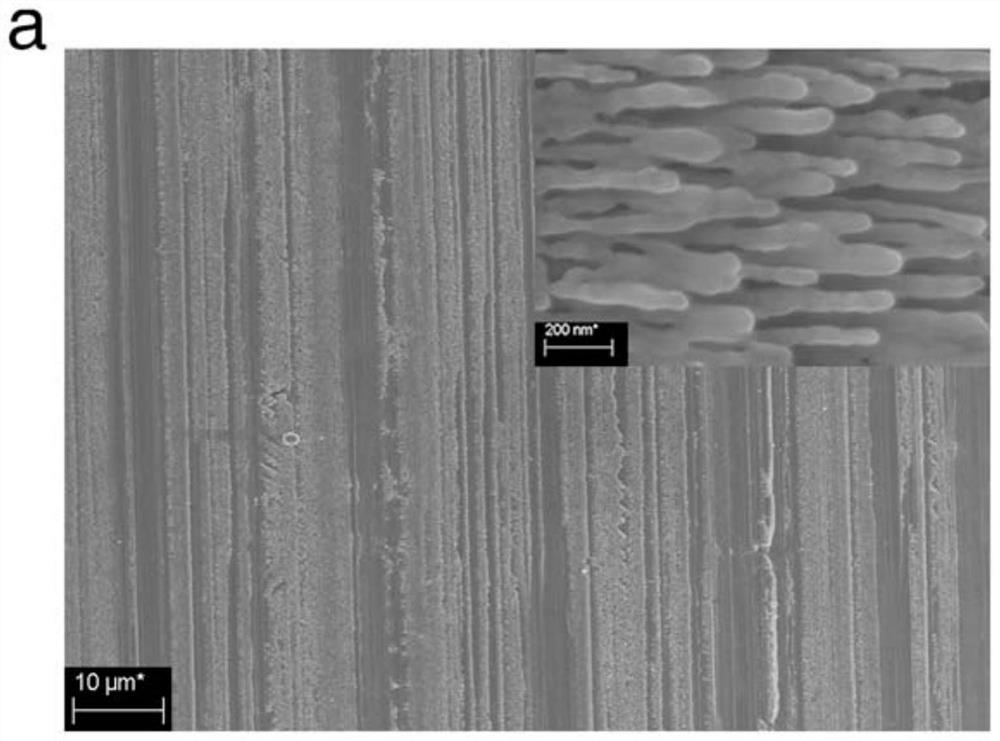

[0037] 3. Fix the copper foil flatly on the substrate stage, divide the copper foil into two groups, one group makes the copper foil scratches along the vertical direction, and the other group makes the copper foil scratches along the horizontal direction; adjust the substrate The angle of the table normal makes the included angle between the direction of the evaporation beam flow and the normal of the substrate table be 86°, and the silver nanowires with a crystal oscillator of 800 nm are grown obliquely on the substrate of the substrate table to obtain a surface-enhanced Raman scattering substrate ;

[0038] 4. Preparation 10 -5 ...

Embodiment 2

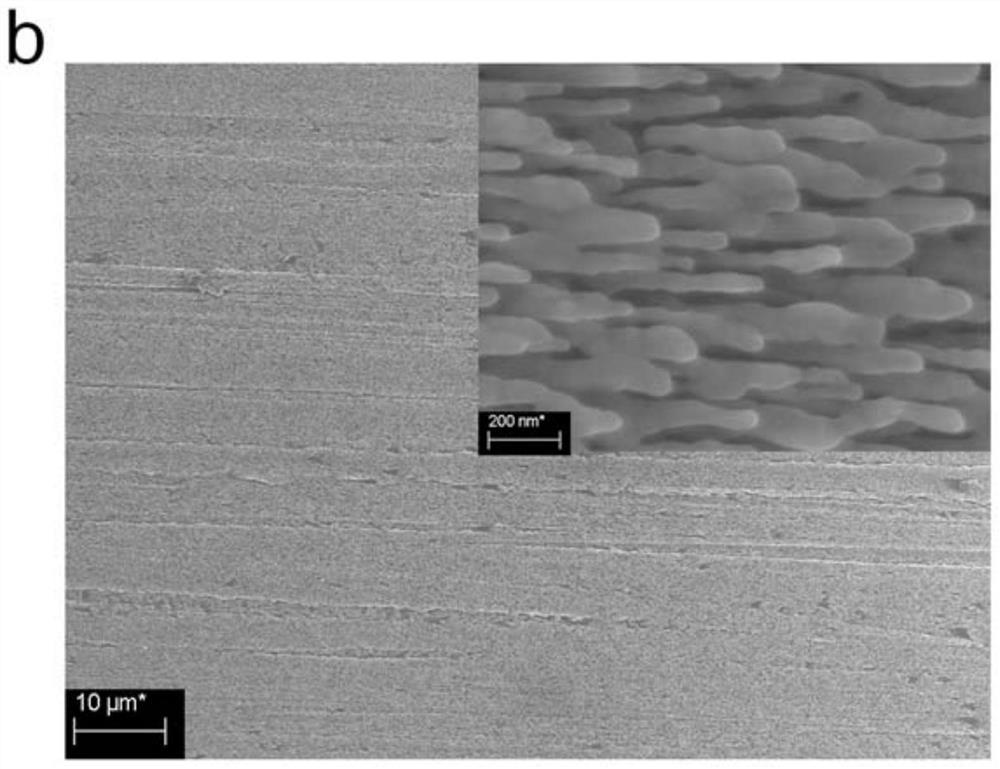

[0044] 1. Deposit 0, 40, 60, 80, 100, 120 cycles of aluminum oxide on the cleaned copper foil with a thickness of 50 μm at 150 ° C;

[0045] 2. At room temperature, using high-purity silver as the evaporation target, pump the reaction chamber of the electron beam evaporation deposition coating machine to 5×10 -5 Pa high vacuum;

[0046] 3. Fix the copper foil on the substrate table so that the scratches on the copper foil are in the vertical direction, and adjust the angle of the normal line of the substrate table so that the angle between the direction of the evaporation beam and the normal line of the substrate table is 86°. On the base of the stage, silver nanowires with a diameter of 800nm are obliquely grown on the crystal oscillator to obtain a surface-enhanced Raman scattering substrate;

[0047] 4. Preparation 10 -5 The rhodamine 6G (R6G) solution of mol / L;

[0048] 5. Cut the surface-enhanced Raman scattering substrate prepared in step 3 into a 5mm square piece, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com