Titanium-based functional material with aperture gradient structure, preparation method and application

A titanium-based functional material with a pore gradient structure, its preparation method and its application technology, which can be applied in the directions of additive manufacturing, manufacturing tools, additive processing, etc., can solve the problems of poor plasticity and high elastic modulus, and meet the needs of growth , expanding contact area, good academic value and clinical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

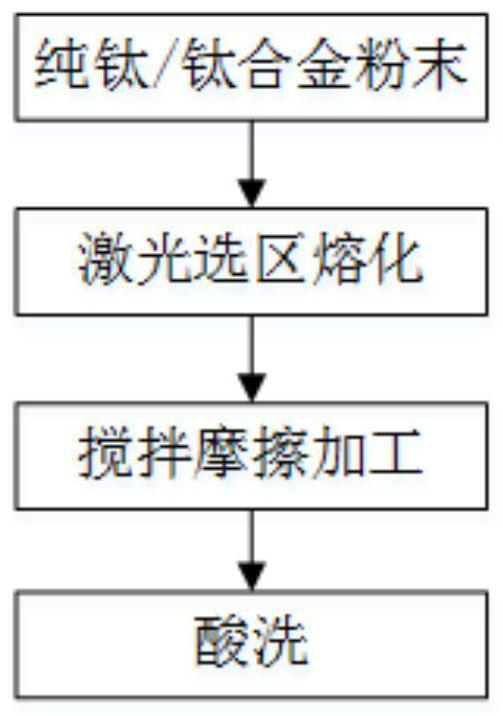

[0030] The present invention proposes a titanium-based functional material with a pore size gradient structure and a preparation method thereof, including: the method first uses laser selective melting technology to prepare a pure titanium or titanium alloy substrate plate, and then punches or grooves on the plate, The holes or slots are filled with pure aluminum powder, then processed by friction stir method, and finally pickled to remove clusters of aluminum particles, form a porous structure, and obtain a porous titanium-based functional material with a pore size gradient structure.

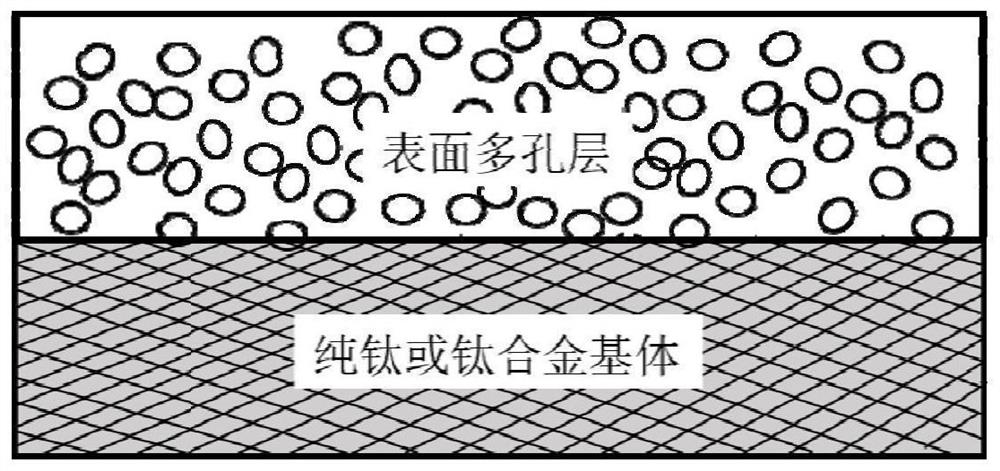

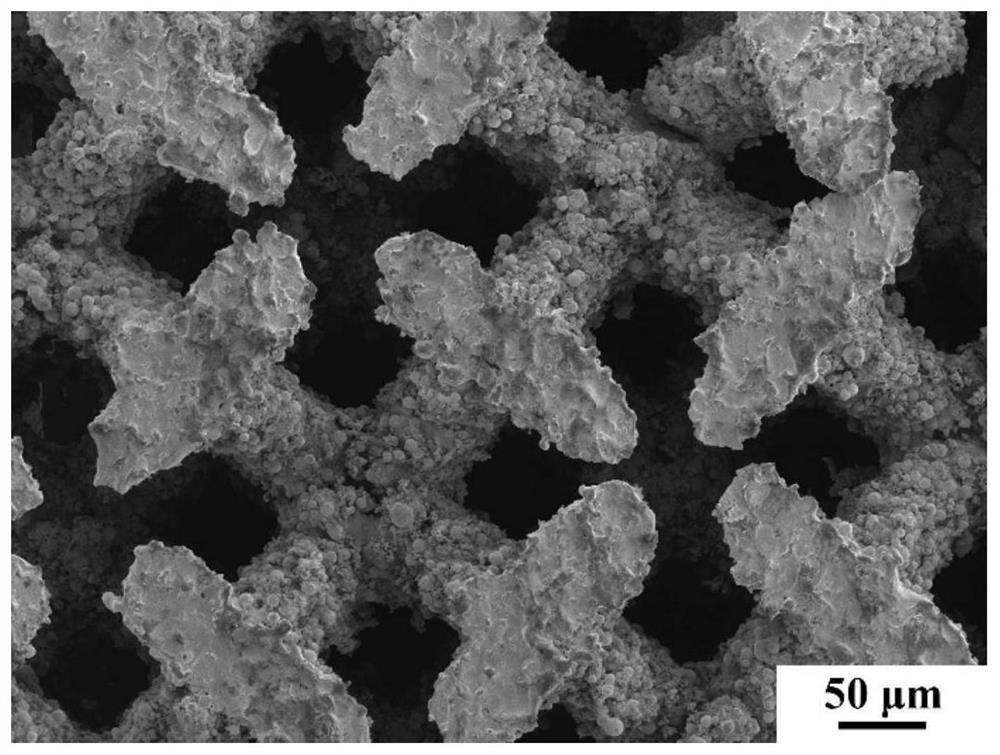

[0031] combine figure 2 , the surface layer of the titanium-based functional material with a pore size gradient structure prepared by the present invention is a fine porous layer with a crossed pore structure, and the inner layer is a loose porous layer. The surface layer and the matrix have different pore structures, which are beneficial to the growth and fusion of bone tissue, and have good...

Embodiment 1

[0048] A method for preparing a titanium-based functional material with a pore size gradient structure, comprising the following steps:

[0049] Step 1: Put pure titanium powder with a particle size distribution range of 5 to 50 μm in the powder box of laser selective melting equipment, the gas used is argon, the laser power is 400W, the powder coating thickness is 0.04mm, and the laser scanning distance is 0.09mm , the laser scanning rate is 1700mm / s, and the thickness of the prepared pure titanium substrate is 5mm.

[0050] Step 2: Drill holes on the surface of the pure titanium substrate, the hole depth is 1.5mm, the hole diameter is 2mm, and the hole spacing is 2mm.

[0051] Step 3: Fill the hole with pure aluminum powder, and perform friction stir processing on the substrate after adding the powder. The rotation speed of the stirring head is 1180r / min, the forward speed is 23.5mm / min, and the shoulder reduction is 0.5 mm, the length of the stirring needle is 1.5mm.

[0...

Embodiment 2

[0057] A method for preparing a titanium-based functional material with a pore size gradient structure, comprising the following steps:

[0058] Step 1: Place TC4 powder with a particle size distribution range of 20-60 μm in the powder box of laser selective melting equipment, the gas used is argon, the laser power is 400W, the powder coating thickness is 0.04mm, and the laser scanning distance is 0.09mm. The laser scanning rate is 1700mm / s, and the thickness of the prepared TC4 substrate is 5mm.

[0059] Step 2: Drill holes on the surface of the TC4 substrate, the hole depth is 1.5mm, the hole diameter is 1.5mm, and the hole spacing is 1.5mm.

[0060] Step 3: Fill the hole with pure aluminum powder, and perform friction stir processing on the substrate after adding the powder. The rotation speed of the stirring head is 1180r / min, the forward speed is 23.5mm / min, and the shoulder reduction is 0.5 mm, the length of the stirring needle is 1.5mm.

[0061] Step 4: Pickling it, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com