A method for high-clean and non-destructive transfer of graphene nanoribbons

A graphene nanoribbon, clean technology, applied in the direction of graphene, single-layer graphene, nano carbon, etc., can solve the problem of unrealizable, complicated transfer of graphene nanoribbons, and obtain ultra-clean high-quality graphene nanoribbons Difficulties and other problems, to achieve the effect of avoiding stacking, avoiding agglomeration, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

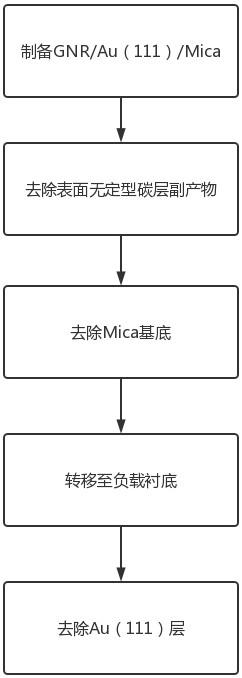

[0024] A kind of method that the present invention proposes highly clean nondestructive transfer graphene nanoribbon, concrete steps are as follows:

[0025] (1) The Mica substrate is ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 20 minutes in sequence, the purpose of which is to remove organic impurities and dust on the surface of the Mica;

[0026] (2) Transfer the cleaned Mica substrate to a plasma-assisted magnetron sputtering apparatus, replace the pure gold target, and grow a 30nm-thick Au(111) layer on the Mica substrate to obtain the Au(111) / Mica growth substrate.

[0027] (3) The Au(111) / Mica sample obtained in step (2) was washed with absolute ethanol to remove surface impurities, and transferred to a plasma-assisted CVD furnace, using ethylene as the growth source gas, on the Au(111) surface A single layer of N=7 GNR is grown, where N=7 means that the graphene nanoribbon width is 7 atoms wide, and N=7 GNR / Au(111) / Mica sample is obtai...

Embodiment 2

[0036] A method for highly clean and non-destructive transfer of graphene nanoribbons, the specific steps are as follows:

[0037] (1) The Mica substrate is ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 20 minutes in sequence, the purpose of which is to remove organic impurities and dust on the surface of the Mica;

[0038] (2) Transfer the cleaned Mica substrate to a plasma-assisted magnetron sputtering apparatus, replace the pure gold target, and grow a 30nm-thick Au(111) layer on the Mica substrate to obtain the Au(111) / Mica growth substrate.

[0039] (3) The Au(111) / Mica sample obtained in step (2) was washed with absolute ethanol to remove surface impurities, and transferred to a plasma-assisted CVD furnace, using ethylene as the growth source gas, on the Au(111) surface A single layer of N=7 GNR is grown, where N=7 means that the graphene nanoribbon width is 7 atoms wide, and N=7 GNR / Au(111) / Mica sample is obtained.

[0040] (4) During t...

Embodiment 3

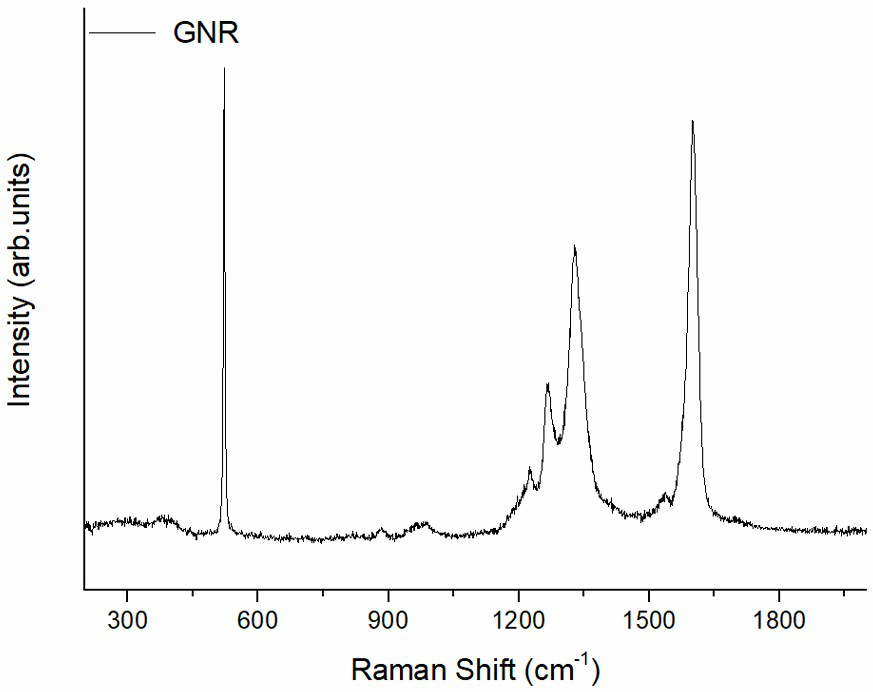

[0050] The difference between this example and Example 1 is that the iodine solution of potassium iodide in step (9) in Example 1 is replaced by nitrohydrochloric acid configured with concentrated hydrochloric acid and concentrated nitric acid in a volume ratio of 1:3, and the solution is dropped on the surface of the sample. On , the iodine solution of potassium iodide slowly etches the Au(111) layer. The Au(111) coating is completely etched, and the etching solution is blotted dry with dust-free paper, then washed repeatedly with deionized water and absolute ethanol, and then dried on a heating platform at 60°C to obtain graphene nanoribbons sample. The purpose of this example is to verify the effect of the etching speed of the Au(111) coating on the transfer quality of graphene nanoribbons. Raman multi-point test results show the I of the transferred graphene nanoribbons 2d / I G The value of is reduced, and some blanks appear at the same time. This indicates that the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com