Preparation method of aminated graphene oxide

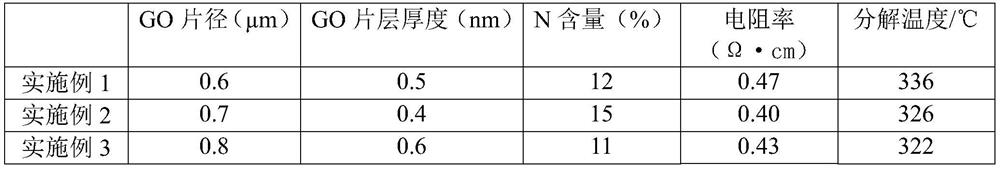

A technology of amination and graphene, which is applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of poor electrical conductivity and high temperature resistance, and achieve enhanced electrical conductivity and thermal stability, small sheet diameter, layered low number effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

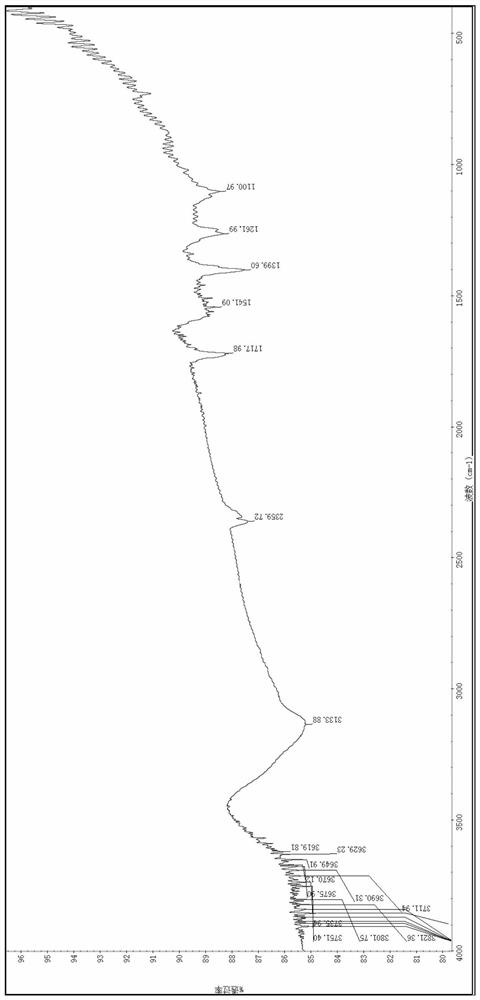

Image

Examples

Embodiment 1

[0031] Step 1, uniformly disperse 50kg of graphene oxide in 1000kg of solvent N, N-dimethylformamide (DMF) through ultrasonic, shearing, and emulsified composite dispersion methods, add thionyl chloride and oxychloride at 5°C The mass ratio of sulfone to graphene oxide powder is 1:4. After the dropwise addition is completed, the temperature is raised to 60°C for reaction. During the reaction, condensation is refluxed and exhaust gas is absorbed at the same time. After 12 hours of reaction, an appropriate amount of water is slowly added until there is no Gas is generated, then suction filtered and washed to obtain activated acyl chloride-based graphene oxide.

[0032] Step 2: Add 100kg of polyphosphoric acid into the reaction kettle, heat to 160°C, then add 16.7kg of p-nitrobenzoic acid and 12kg of semicarbazide hydrochloride, a large amount of gas will be generated immediately, stir vigorously to make the mixture uniform. The temperature was raised to 160°C for 2 hours. After...

Embodiment 2

[0036] Step 1, uniformly disperse 50kg of graphene oxide in 1000kg of solvent DMF through ultrasonic, shearing, and emulsified composite dispersion methods, add thionyl chloride at 10°C, and the mass ratio of thionyl chloride to graphene oxide powder is 1:3, after the dropwise addition is completed, the temperature is raised to 60°C for reaction. During the reaction, reflux is condensed and tail gas is absorbed at the same time. After 10 hours of reaction, an appropriate amount of water is slowly added until no gas is generated in the system, and then filtered and washed to obtain activation acyl chloride-based graphene oxide.

[0037] Step 2: Add 100kg of polyphosphoric acid into the reaction kettle, heat to 150°C, then add 16.7kg of p-nitrobenzoic acid and 12kg of semicarbazide hydrochloride, a large amount of gas will be generated immediately, stir vigorously to make the mixture uniform. The temperature was raised to 150°C for 5h. After the reaction solution is cooled, pou...

Embodiment 3

[0043] Step 1, uniformly disperse 50kg of graphene oxide in 1000kg of solvent DMF through ultrasonic, shearing, and emulsified composite dispersion methods, add thionyl chloride at 10°C, and the mass ratio of thionyl chloride to graphene oxide powder is 1:3, after the dropwise addition is completed, the temperature is raised to 60°C for reaction. During the reaction, reflux is condensed and tail gas is absorbed at the same time. After 10 hours of reaction, an appropriate amount of water is slowly added until no gas is generated in the system, and then filtered and washed to obtain activation acyl chloride-based graphene oxide.

[0044] Step 2: Add 100kg of polyphosphoric acid into the reaction kettle, heat to 160°C, then add 16.7kg of p-nitrobenzoic acid and 12kg of semicarbazide hydrochloride, a large amount of gas will be generated immediately, stir vigorously to make the mixture uniform. The temperature was raised to 150°C for 5h. After the reaction solution is cooled, pou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com