Polyacrylate elastomer, hybrid network system material thereof and display screen protective film prepared from polyacrylate elastomer and hybrid network system material

A polyacrylate, acrylate technology, applied in chemical instruments and methods, synthetic resin layered products, film/sheet release liners, etc., can solve problems such as poor impact resistance, difficult folding, and easy creases , to achieve the effect of good impact resistance and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 polyacrylate elastomer

[0036] This embodiment provides a random copolymer composed of butyl acrylate repeating units and acrylate repeating units containing UPy groups. Its molecular structural formula is as follows:

[0037]

[0038] Among them, the value of m is 45, and the value of n is 104

[0039] The preparation method of the polyacrylate elastomer of this embodiment is: Utilize radical polymerization, synthesize acrylate elastomer, 70 parts of butyl acrylate, 30 parts of Upy monomer, 0.001 part of AIBN, 0.2 part of ethyl acetate solvent, in Reaction at 70°C for 12h. The molecular formula of Upy monomer is as follows:

[0040]

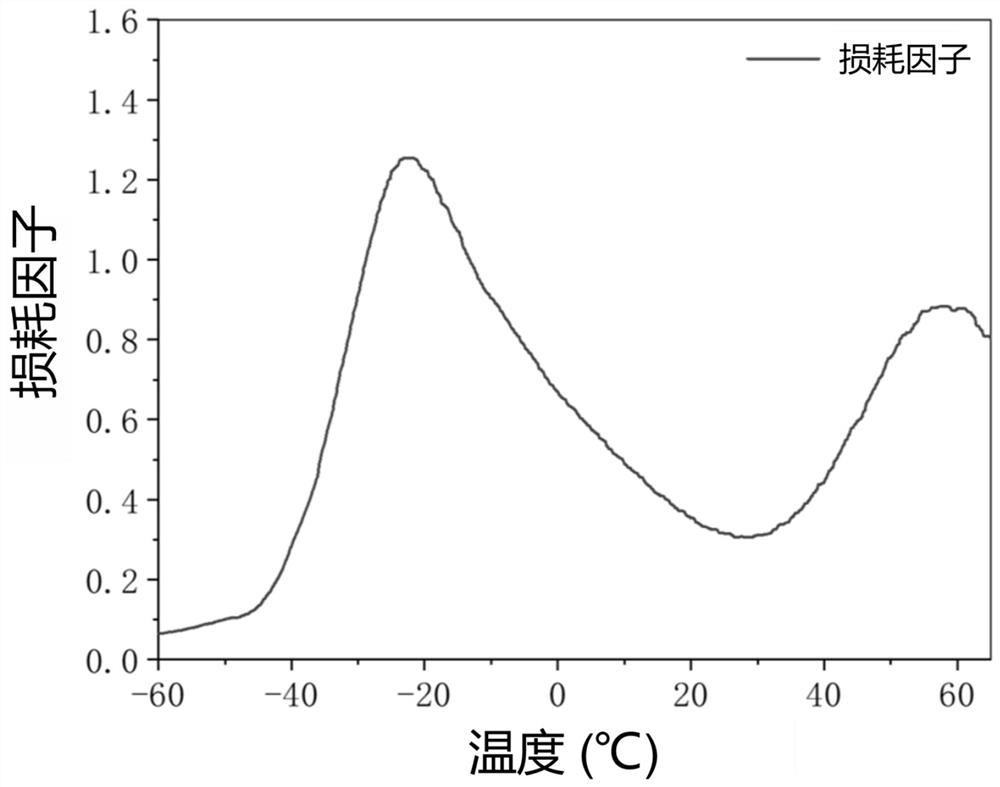

[0041] The polyacrylate elastomer described in this embodiment, its damping performance adopts the method test specified in ASTM E756-1993 standard, the result is as follows figure 1 As shown, the temperature range where the loss factor is higher than 0.3 is from -50°C to 60°C, which has a wide temperature range, w...

Embodiment 2

[0042] Embodiment 2 display screen protective film

[0043]In this example, the polyacrylate elastomer of Example 1 is used, and 2 g of the polyacrylate elastomer material is dissolved in 1 ml of tetrahydrofuran solvent to obtain a tetrahydrofuran solution of the polyacrylate elastomer, and the solution of the polyacrylate elastomer is poured on a 50 μm thick On the transparent PET plastic film (company: Suzhou Aiqiu Electronics Co., Ltd., product model: AQ2ST31HC), a protective film with a dry film thickness of 50 μm was obtained by precision coating, dried and cured in a vacuum oven at 80 ° C for 2-3 hours, and coated A 50 μm thick release PET film (company: Suzhou Aiqiu Electronics Co., Ltd., product model: AQ-LX3T) was attached to the layer to obtain a protective film for the display screen.

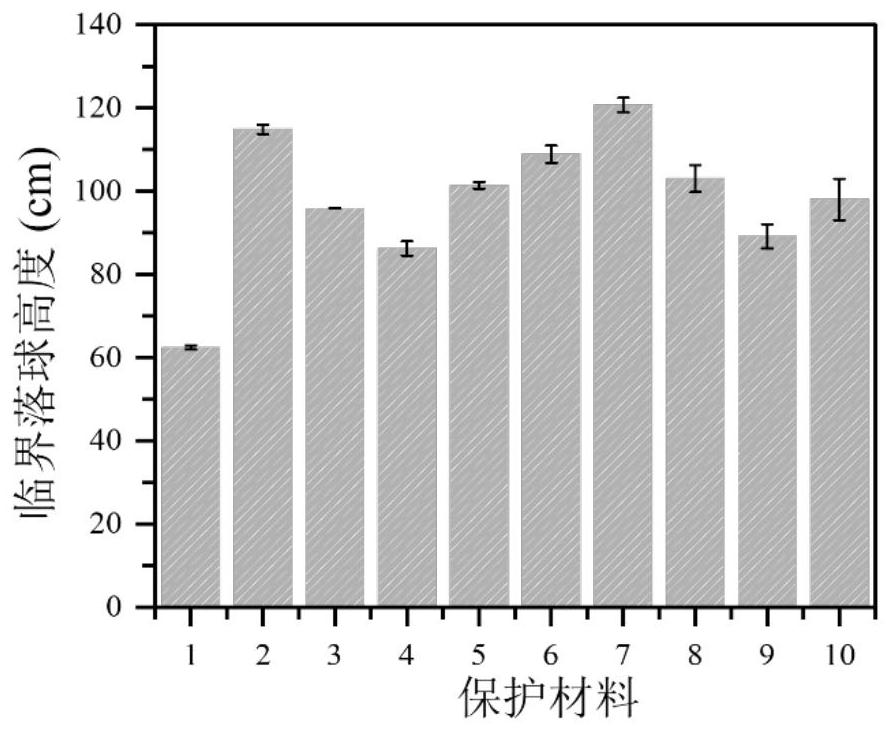

[0044] The 0.5mm thick tempered glass protected by the protective film can withstand the free fall of a small steel ball (diameter 10mm, weight 4g) with a critical height of 115cm. ...

Embodiment 3

[0045] Embodiment 3 display screen protective film

[0046] This embodiment adopts the polyacrylate elastomer of Example 1, and dissolves 1 g of polyacrylate elastomer, 1 g of polydimethylsiloxane (number average molecular weight 80,000 g / mol) and a small amount of curing agent DCP in 1 ml of tetrahydrofuran solvent, Obtain the mixed solution, pour the mixed solution on a transparent PET plastic film (company: Suzhou Aiqiu Electronics Co., Ltd., product model: AQ2ST31HC) with a thickness of 50 μm, and adopt a precise coating method to obtain a protective film with a dry film thickness of 50 μm. Dry and cure in a vacuum oven at 80°C for 2-3 hours, and attach a 50 μm thick release PET (company: Suzhou Aiqiu Electronics Co., Ltd., product model: AQ-LX3T) to the coating surface to obtain a display screen protection film.

[0047] The 0.5mm thick tempered glass protected by the protective film of the display screen can withstand the free fall of a small steel ball (diameter 10mm, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com