Microalgae culture medium and method for degrading algal toxin

A culture medium and microalgae technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of fish and shrimp refusal to eat, waste, death, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation of embodiment 1 medium of the present invention

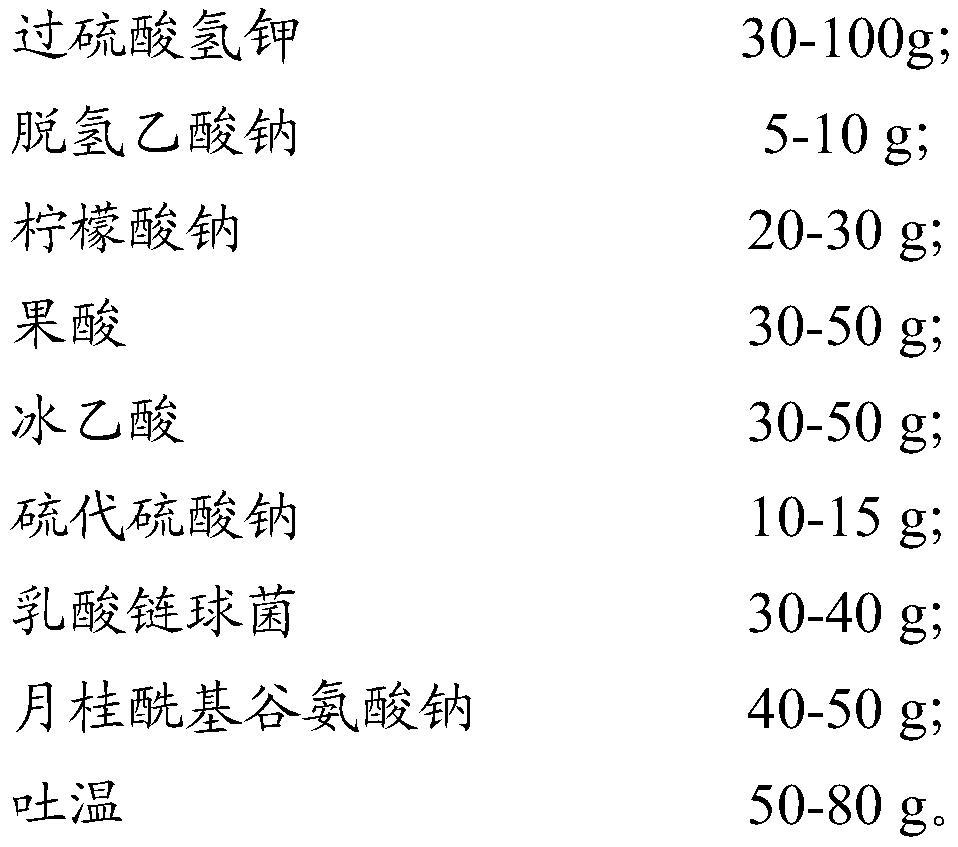

[0038] The composition is shown in Table 1.

[0039] Table 1 Medium formula composition

[0040]

[0041]

[0042] Preparation method:

[0043] 1. Boil 500ml of purified water, put in three materials A, B, and C in turn, stir well until completely dissolved.

[0044] 2. Place the material liquid in step 1 to cool to room temperature, then add three materials D, E, and F in sequence, and stir to mix evenly.

[0045] 3. In the material liquid of step 2, slowly add material H while stirring. After it is completely dissolved, add material I and mix evenly.

[0046] 4. Finally, add material G, and dilute to 1 L with purified water to obtain the culture medium described in this patent.

Embodiment 2

[0047] The preparation of embodiment 2 medium of the present invention

[0048] The formula composition is shown in Table 2, and the preparation method is the same as in Example 1.

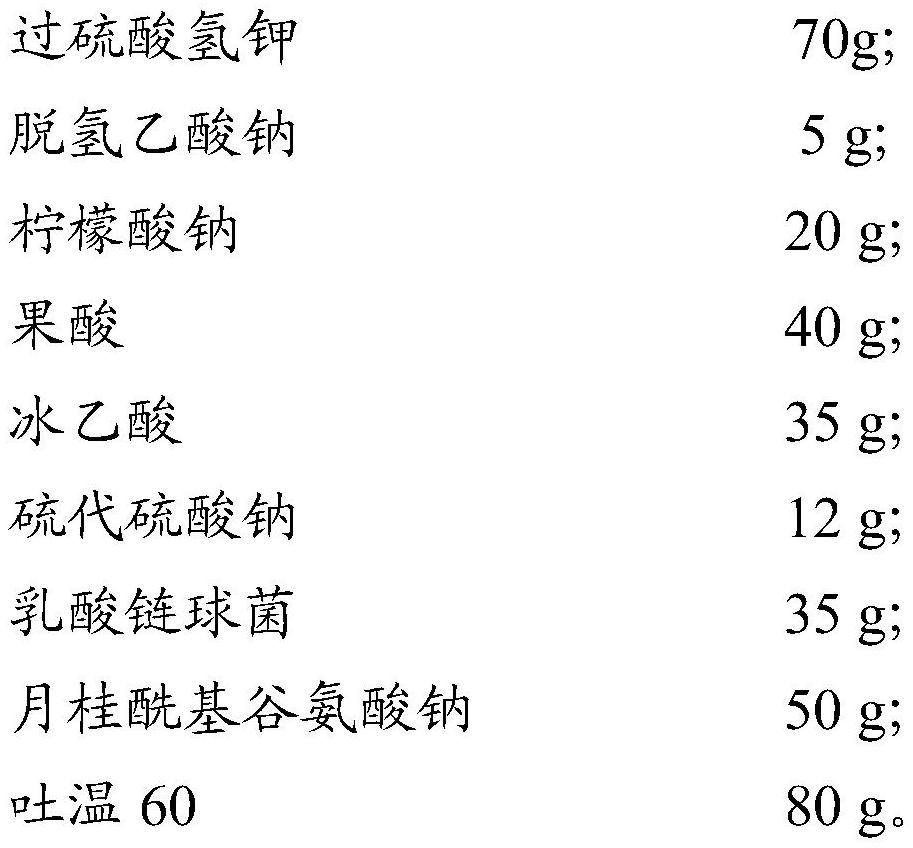

[0049] Table 2 Medium formula composition

[0050] serial number Material name weight A Potassium persulfate 80g B Sodium dehydroacetate 10g C Sodium citrate 25g D fruit acid 35g E Glacial acetic acid 50g F Sodium thiosulfate 15g G Lactococcus 40g H Sodium Lauroyl Glutamate 50g I Tween 80 80g

Embodiment 3

[0051] The preparation of embodiment 3 medium of the present invention

[0052] The formula composition is shown in Table 3, and the preparation method is the same as in Example 1.

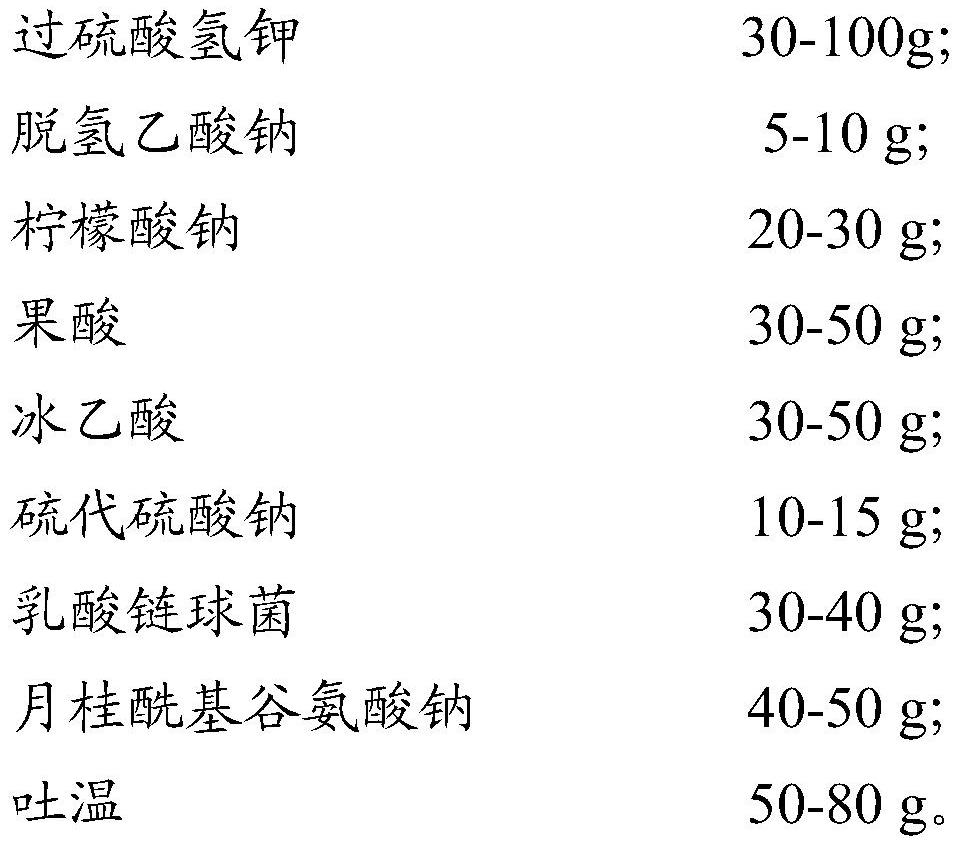

[0053] Table 3 Medium formula composition

[0054] serial number Material name weight A Potassium persulfate 70g B Sodium dehydroacetate 5g C Sodium citrate 20g D fruit acid 40g E Glacial acetic acid 35g F Sodium thiosulfate 12g G Lactococcus 35g H Sodium Lauroyl Glutamate 50g I Tween 60 80g

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com