A kind of preparation method of nano-sensing paste for sucrose detection chip printing

A technology for detecting chips and sensing pastes, which can be used in measurement devices, analytical materials, and electrochemical variables of materials, etc., can solve the problems of fast and accurate detection, time-consuming operations, and cumbersome equipment at the same time, and achieve good market application prospects. , low cost, the effect of improving the linear range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method for nano-sensing slurry printed on a sucrose detection chip, comprising the following steps:

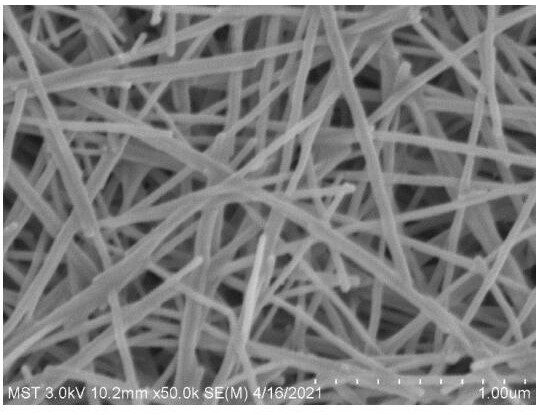

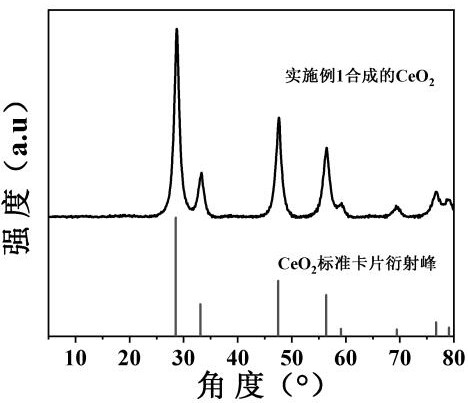

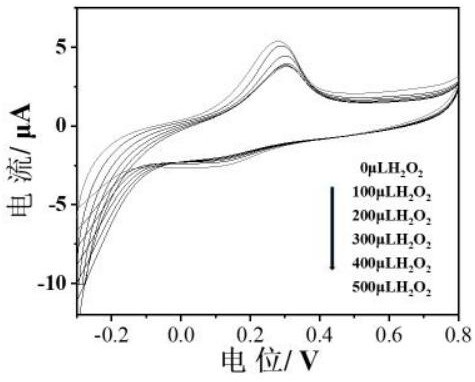

[0035] (1) Weigh 0.037258g (0.1mmol) cerium chloride heptahydrate and dissolve it in 100mL deionized water, stir the solution until it is clear and transparent to obtain solution A, weigh 2.9g (0.1mmol) polyvinylpyrrolidone and dissolve it in 100mL deionized water In water, stir the solution until it is clear and transparent to obtain solution B. Mix solutions A and B and continue to stir for 30 minutes. Add about 3mL of ammonia water to the mixed solution to make the pH = 7. At this time, the solution becomes a light red flocculent suspension. Continue to After stirring for 30 minutes, transfer the suspension into a hydrothermal kettle. The temperature of the hydrothermal kettle is controlled at 90°C, and the heating time is 24 hours. After the hydrothermal reaction is completed, the product is cooled to room temperature, taken out and transferred to a 50m...

Embodiment 2

[0049] A preparation method for nano-sensing slurry printed on a sucrose detection chip, comprising the following steps:

[0050] (1) Weigh 0.1864g (0.5mmol) cerous chloride heptahydrate and dissolve it in 100mL deionized water, stir the solution until it is clear and transparent to obtain solution A, weigh 5.8g (0.2mmol) polyvinylpyrrolidone and dissolve it in 100mL deionized water In water, stir the solution until it is clear and transparent to obtain solution B. Mix solutions A and B and continue to stir for 30 minutes. Add 4ml of ammonia water to the mixed solution to make the pH = 8. At the same time, the solution becomes a light red flocculent suspension and continue to stir for 30 minutes. Finally, the suspension was transferred to a hydrothermal kettle, the temperature of the oven was controlled at 110°C, and the heating time was 20 hours. After cooling to room temperature, it was taken out and moved into a 50ml centrifuge tube, and water and ethanol were added to centr...

Embodiment 3

[0059] A preparation method for nano-sensing slurry printed on a sucrose detection chip, comprising the following steps:

[0060](1) Weigh 0.74516g (2mmol) cerous chloride heptahydrate and dissolve it in 100mL deionized water, stir the solution until it is clear and transparent to obtain solution A, weigh 14.5g (0.5mmol) polyvinylpyrrolidone and dissolve it in 100mL deionized water , Stir the solution until it is clear and transparent to obtain solution B. Mix solutions A and B and continue to stir for 30 minutes. Add 5 mL of ammonia water to the mixed solution to make the pH = 9. At the same time, the solution becomes a light red flocculent suspension. Continue to stir for 30 minutes. Transfer this suspension into a hydrothermal kettle, control the oven temperature at 135°C, and heat for 16 hours. After cooling to room temperature, take it out and transfer it to a 50ml centrifuge tube, add water and ethanol to centrifuge and wash three times, and set the centrifuge speed to 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com