Gradient slow-release polycarboxylate superplasticizer as well as preparation method and application thereof

A slow-release polycarboxylic acid and water-reducing agent technology, applied in the field of water-reducing agents, can solve the problems of affecting the construction progress and construction quality, difficult to maintain the slump of concrete for a long time, and the slow-release time is limited. Time and preparation method are simple and easy to operate, and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

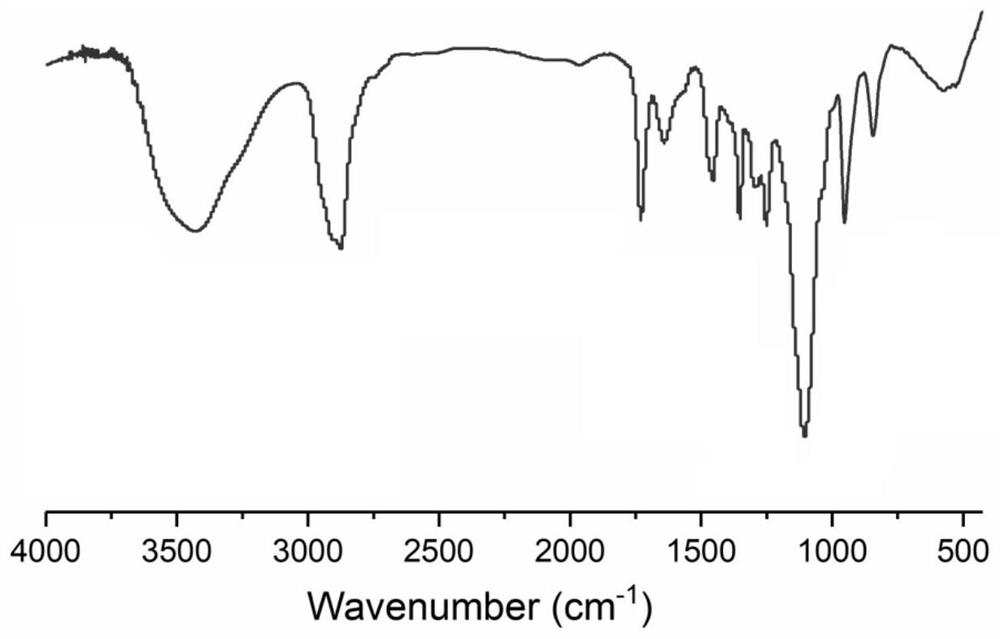

Image

Examples

Embodiment 1

[0038] A gradient slow-release polycarboxylate superplasticizer HS-1, prepared by the following method:

[0039] (1) Weigh 330 parts of methallyl polyoxyethylene ether (molecular weight 3000Da), 15 parts of acrylic acid, 15 parts of hydroxyethyl acrylate, 12.5 parts of hydroxypropyl acrylate, 4 parts of sodium hypophosphite, 10 parts of ferrous sulfate Aqueous solution (concentration 0.3wt%), 0.45 parts of ascorbic acid, 2.5 parts of hydrogen peroxide.

[0040] (2) Mix methallyl polyoxyethylene ether, 2.5 parts of hydroxypropyl acrylate, sodium hypophosphite and ferrous sulfate aqueous solution, add 330 parts of water to obtain solution A.

[0041] (3) Mix acrylic acid, hydroxyethyl acrylate and 10 parts of hydroxypropyl acrylate, and add 60 parts of water to obtain solution B.

[0042] (4) Mix ascorbic acid with 60 parts of water to obtain solution C.

[0043] (5) At 20°C, add hydrogen peroxide to solution A and mix evenly. At the same time, start to add solution B and solu...

Embodiment 2

[0046] A gradient slow-release polycarboxylate superplasticizer HS-2, prepared by the following method:

[0047] (1) Weigh 350 parts of isopentenol polyoxyethylene ether (molecular weight 3300Da), 16 parts of methacrylic acid, 18 parts of hydroxyethyl acrylate, 14.5 parts of hydroxyethyl methacrylate, 5 parts of sodium methacrylate , 12 parts of ferrous sulfate aqueous solution (concentration 0.3wt%), 0.5 part of sodium formaldehyde sulfoxylate, 3.0 parts of hydrogen peroxide.

[0048] (2) Mix prenol polyoxyethylene ether, 3.5 parts of hydroxyethyl methacrylate, sodium methacrylate and ferrous sulfate aqueous solution, and add 350 parts of water to obtain solution A.

[0049] (3) Mix methacrylic acid, hydroxyethyl acrylate and 11 parts of hydroxyethyl methacrylate, and add 60 parts of water to obtain solution B.

[0050] (4) Mix sodium formaldehyde sulfoxylate with 60 parts of water to obtain solution C.

[0051] (5) At 20°C, add hydrogen peroxide to solution A and mix evenl...

Embodiment 3

[0053] A gradient slow-release polycarboxylate superplasticizer HS-3, prepared by the following method:

[0054] (1) Weigh 360 parts of methyl alkenyl polyoxyethylene ether (molecular weight 3000Da), 16 parts of acrylic acid, 20 parts of hydroxyethyl acrylate, 4 parts of hydroxypropyl methacrylate, 10 parts of hydroxypropyl acrylate, 5 parts of Sodium phosphate, 10 parts of ferrous sulfate aqueous solution (0.3 wt%), 0.6 parts of sodium bisulfite, 3.0 parts of hydrogen peroxide.

[0055] (2) Mix methyl alkenyl polyoxyethylene ether, hydroxypropyl methacrylate, sodium hypophosphite and ferrous sulfate aqueous solution, add 360 parts of water to obtain solution A.

[0056] (3) Mix acrylic acid, hydroxyethyl acrylate and hydroxypropyl acrylate, and add 60 parts of water to obtain solution B.

[0057] (4) Mix sodium bisulfite with 60 parts of water to obtain solution C.

[0058] (5) At 20°C, add hydrogen peroxide to solution A and mix evenly. At the same time, start to add solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com