Non-evaporable quaternary Ti-Zr-V-Cu vacuum getter film and preparation method thereof

A ti-zr-v-cu, vacuum suction technology, applied in the fields of chemistry and metallurgy, can solve the problems of local power deposition, increase of resistive wall impedance of vacuum pipeline, and aggravated wake field effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] A method for preparing a non-evaporable quaternary Ti-Zr-V-Cu vacuum getter film, comprising the steps of:

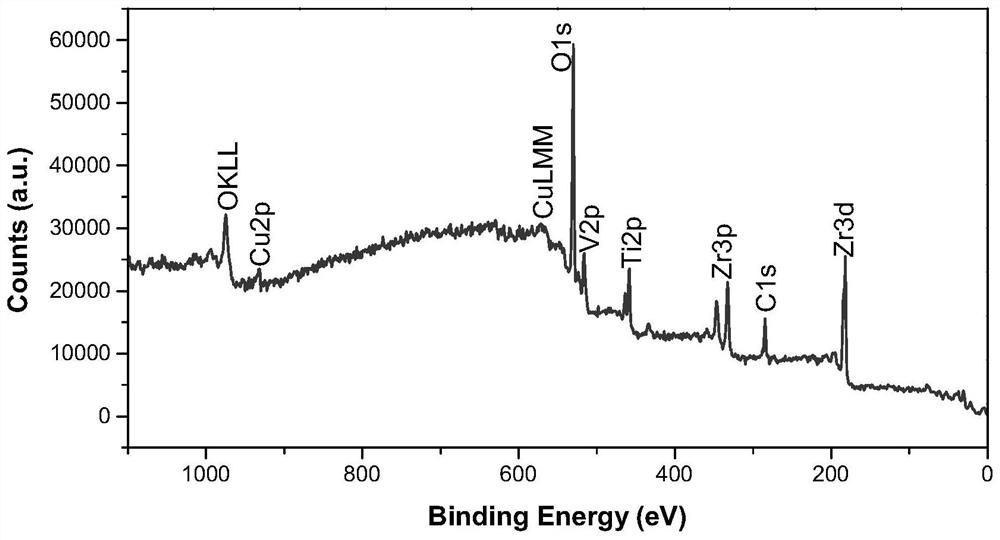

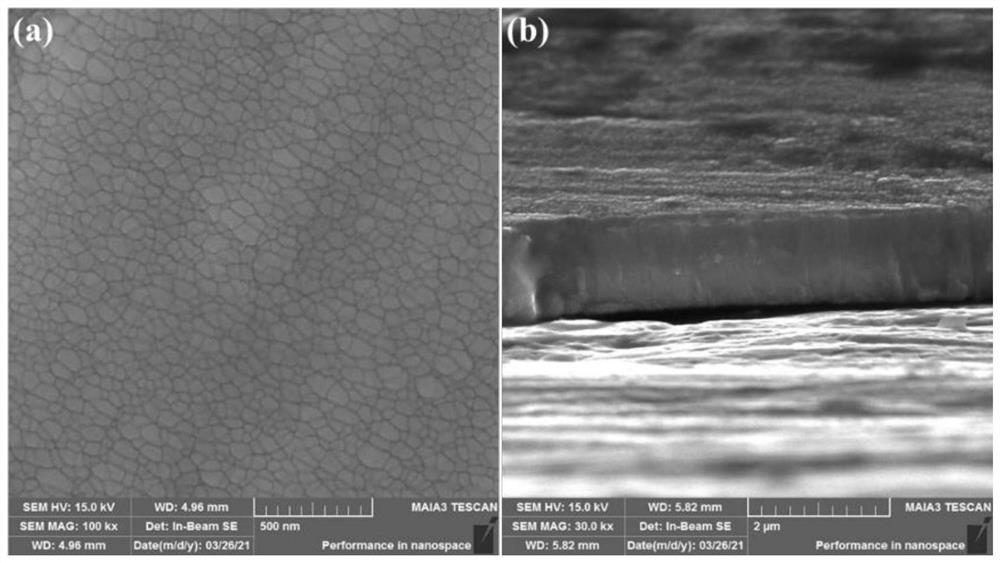

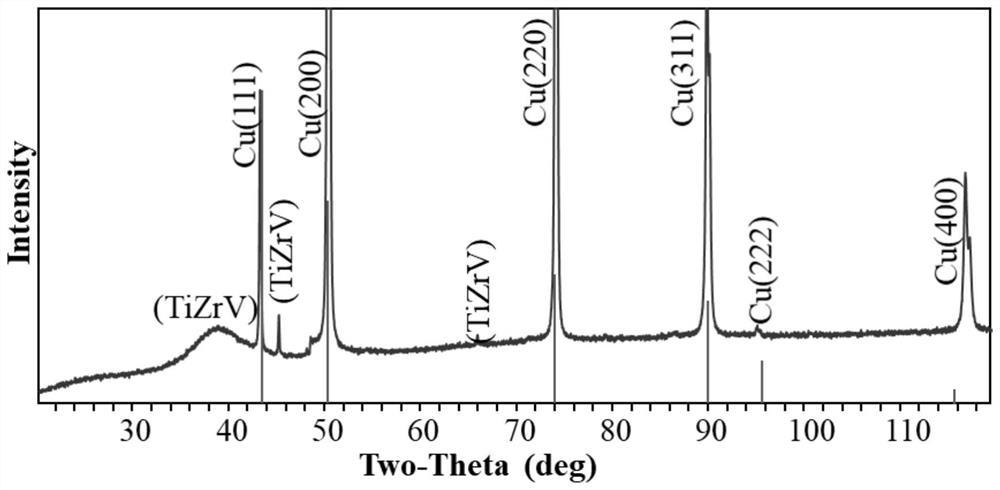

[0063] A dense layer thin film of Ti, Zr, V and Cu is deposited on the base material by magnetron sputtering.

[0064] In some embodiments, the method for preparing the non-evaporable quaternary Ti-Zr-V-Cu vacuum getter thin film further includes the following method: before depositing by magnetron sputtering, plasma cleaning is performed on the base material.

[0065] In some embodiments, the target material used in the magnetron sputtering method is Ti-Zr-V-Cu alloy, the purity of the target material is ≥99.5%; the sputtering gas is Kr, and the pulsed DC sputtering method is adopted Law.

[0066] In some embodiments, the magnetron sputtering method includes the following process: current 0.1-0.5A, working pressure 5-15Pa, deposition time 10-20h, magnetic field current intensity 100-200A.

[0067] In some embodiments, the matrix material is oxygen-free copper ...

Embodiment 1

[0070] This example provides a method for preparing a non-evaporable quaternary Ti-Zr-V-Cu vacuum getter film.

[0071] The preparation method of non-evaporable quaternary Ti-Zr-V-Cu vacuum getter film, comprises the steps:

[0072] On the oxygen-free copper OFC base material, the dense layer film of Ti, Zr, V and Cu is deposited and formed by magnetron sputtering. The target material used in the magnetron sputtering method is Ti-Zr-V-Cu alloy, the purity of the target material is ≥99.5%; the sputtering gas is Kr, and the pulse direct current sputtering method is adopted. The magnetron sputtering method includes the following process: current 0.1A, working pressure 15Pa, deposition time 10h, magnetic field current intensity 200A.

Embodiment 2

[0074] This example provides a method for preparing a non-evaporable quaternary Ti-Zr-V-Cu vacuum getter film.

[0075] The preparation method of non-evaporable quaternary Ti-Zr-V-Cu vacuum getter film, comprises the steps:

[0076] On the oxygen-free copper OFC base material, the dense layer film of Ti, Zr, V and Cu is deposited and formed by magnetron sputtering. The target material used in the magnetron sputtering method is Ti-Zr-V-Cu alloy, the purity of the target material is ≥99.5%; the sputtering gas is Kr, and the pulse direct current sputtering method is adopted. The magnetron sputtering method includes the following process: current 0.5A, working pressure 5Pa, deposition time 20h, magnetic field current intensity 100A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com