Positive electrode composite material and preparation method thereof, positive electrode and lithium battery

A technology of composite materials and positive electrode materials, which is applied in the field of positive electrodes and lithium batteries, positive electrode composite materials and their preparation, can solve problems affecting the structural stability of materials, hindering the development of ternary materials, battery capacity attenuation, etc., to improve cycle stability , Improve structural stability and thermal stability, high thermal safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] In one aspect of the present invention, there is also provided a method for preparing the above-mentioned positive electrode composite material, which includes the following steps:

[0048] The lithium iron phosphate nanosheets grown along the preferred orientation of the ac plane are mixed with the ternary positive electrode material in solid state, so that the lithium iron phosphate nanosheets grown along the preferred orientation of the ac plane cover the ternary positive electrode material.

[0049] Due to the strong electrostatic adsorption between lithium iron phosphate nanosheets and ternary cathode materials, lithium iron phosphate nanosheets can be better coated with ternary cathode materials only through a simple solid-phase mixing process, thereby avoiding the The side reaction between the ternary cathode material and the electrolyte under high voltage is eliminated, and the cycle stability of the electrode material is improved.

[0050] In some embodiments, ...

Embodiment 1

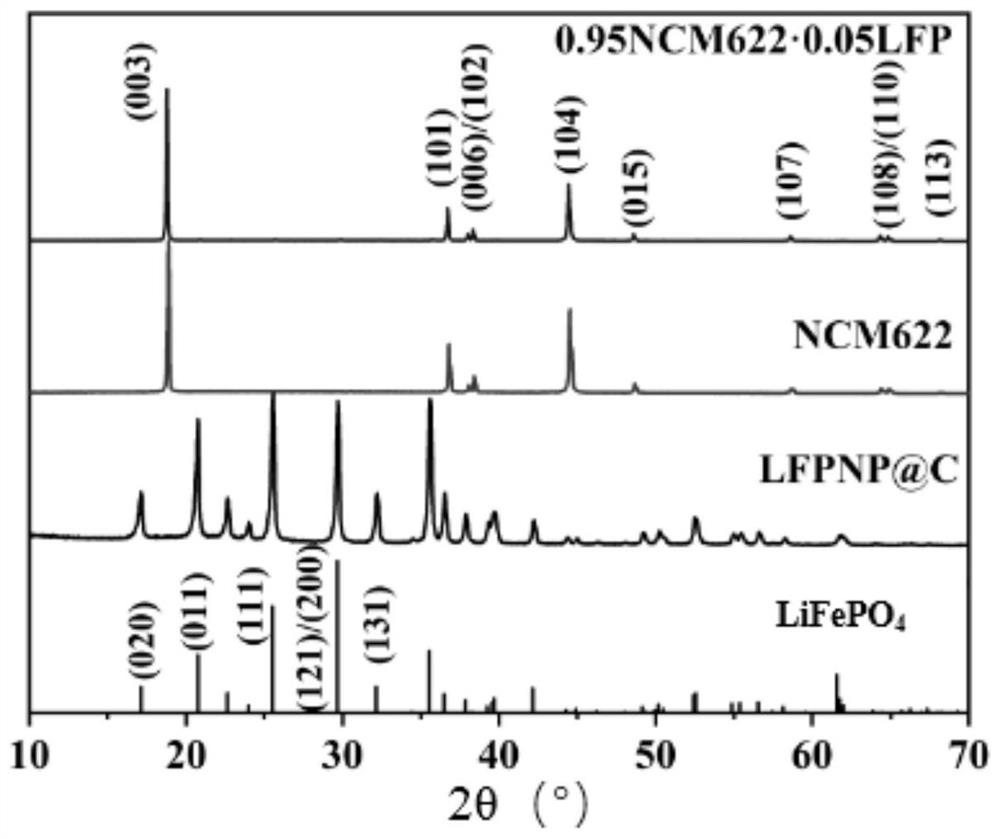

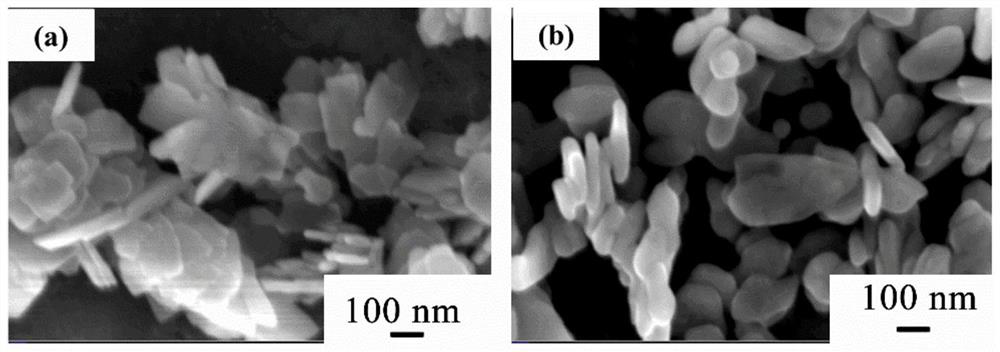

[0072] 1) Preparation of lithium iron phosphate nanosheets grown along the preferred orientation of the ac plane

[0073] LiOH, H with a molar ratio of 3:1:1 3 PO 4 and FeSO 4 Disperse in ethylene glycol and stir to obtain a mixed suspension. The mixed suspension was added to the reactor, and a hydrothermal reaction was carried out at 180 °C for 10 h to obtain a lithium iron phosphate precursor, which was then compounded with glucose and polyvinyl alcohol and sintered at 650 °C in a nitrogen atmosphere for 3 h to obtain Lithium iron phosphate nanosheets grown along the preferred orientation of the ac plane.

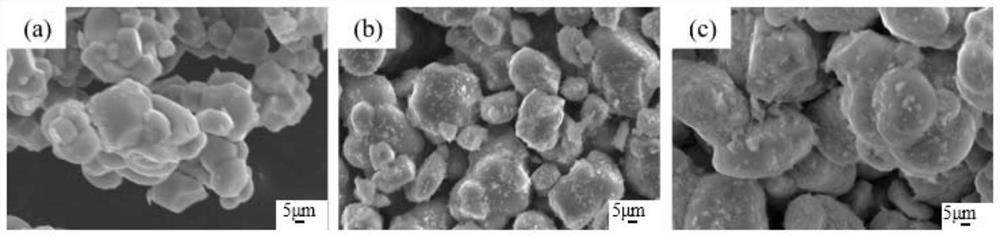

[0074] 2) 0.97 LiNi 0.6 co 0.2 mn 0.2 o 2 @0.03 LiFePO 4 preparation of

[0075] Take 3wt% of the above-mentioned lithium iron phosphate nanosheets grown along the preferred orientation of the ac plane and 97wt% of powdered LiNi 0.6 co 0.2 mn 0.2 o 2 Mix for 12 hours in a three-dimensional mixer without adding balls to prepare 0.97LiNi 0.6 co 0.2 mn 0.2 o ...

Embodiment 2

[0087] The preparation method of this embodiment 2 is basically the same as that of embodiment 1, the difference is: LiFePO 4 The mass percentage content is 5%. Specific steps are as follows:

[0088] 1) Preparation of lithium iron phosphate nanosheets grown along the preferred orientation of the ac plane

[0089] LiOH, H with a molar ratio of 3:1:1 3 PO 4 and FeSO 4 Disperse in ethylene glycol and stir to obtain a mixed suspension. The mixed suspension was added to the reactor, and a hydrothermal reaction was carried out at 180 °C for 10 h to obtain a lithium iron phosphate precursor, which was then compounded with glucose and polyvinyl alcohol and sintered at 650 °C in a nitrogen atmosphere for 3 h to obtain Lithium iron phosphate nanosheets grown along the preferred orientation of the ac plane.

[0090] 2) 0.95 LiNi 0.6 co 0.2 mn 0.2 o 2 @0.05 LiFePO 4 preparation of

[0091] Take 5wt% of the above-mentioned lithium iron phosphate nanosheets grown along the pref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com