Kitchen garbage heat pump drying and MVR concentration treatment device and process

A kitchen waste and treatment device technology, applied in heating water/sewage treatment, waste treatment, water/sewage treatment, etc., can solve the problems of difficult exhaust gas treatment, low energy utilization rate, large heat loss, etc., and reduce energy Consumption, to meet the effect of continuous and stable operation, high energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

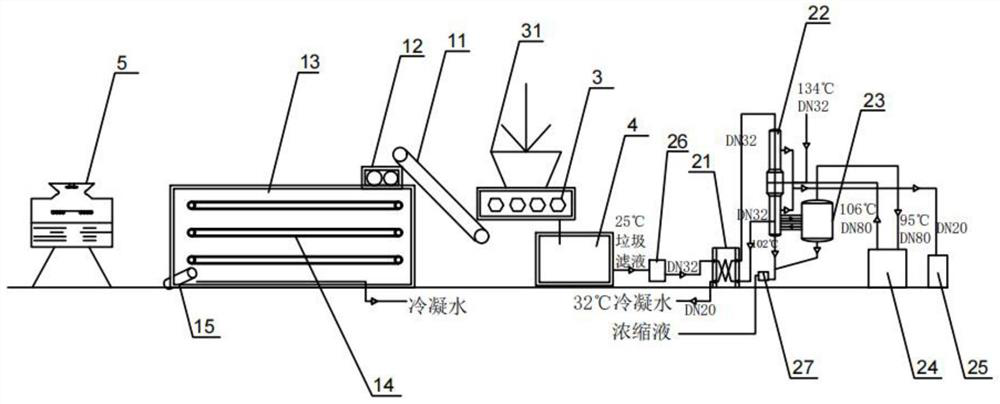

[0037] refer to Figure 1-2 A kitchen waste heat pump drying and MVR concentration treatment device is shown, including a kitchen waste heat pump low-temperature multi-effect drying system 1, a landfill leachate steam mechanical compression concentration system 2, a press 3 and a stock solution pool 4; the stock solution The pool 4 is arranged below the press machine 3, and the two are connected;

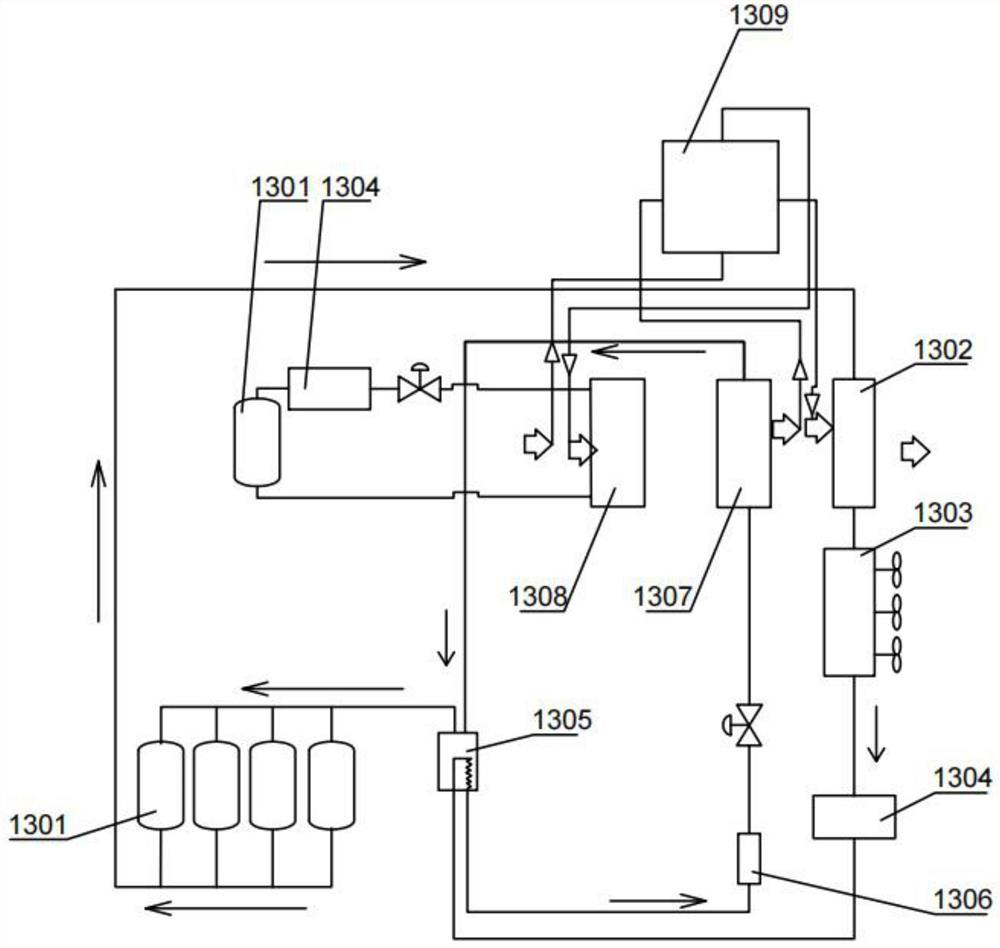

[0038]The kitchen waste heat pump low-temperature multi-effect drying system 1 includes a first conveyor belt 11, an extruder 12, a heat pump low-temperature multi-effect drying unit 13, a plurality of second conveyor belts 14, and a third conveyor belt 15; the first conveyor belt One end of 11 is set on the lower side of one end of the press 3, and the first conveyor belt 11 is set obliquely; the extruder 12 is set on the lower side of the other end of the first conveyor belt; the heat pump low-temperature multi-effect drying unit 13 is fixedly connected to the lower end of the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com