Rare earth tantalate RE3TaO7 spherical powder prepared on basis of molten salt method and preparation method of rare earth tantalate RE3TaO7 spherical powder

A spherical powder and tantalate technology, which is applied in the field of rare earth tantalate RE3TaO7 spherical powder and its preparation, can solve the problems of centrifugal spray granulation loss, low powder purity, high synthesis temperature, etc., and achieve good fluidity , strong controllability and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

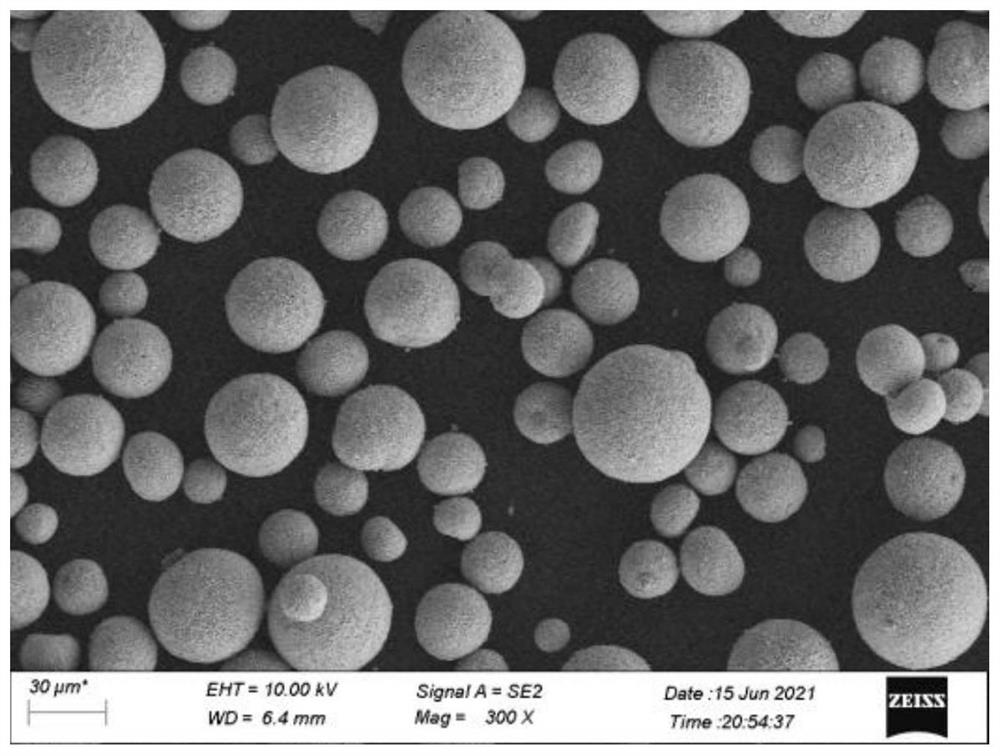

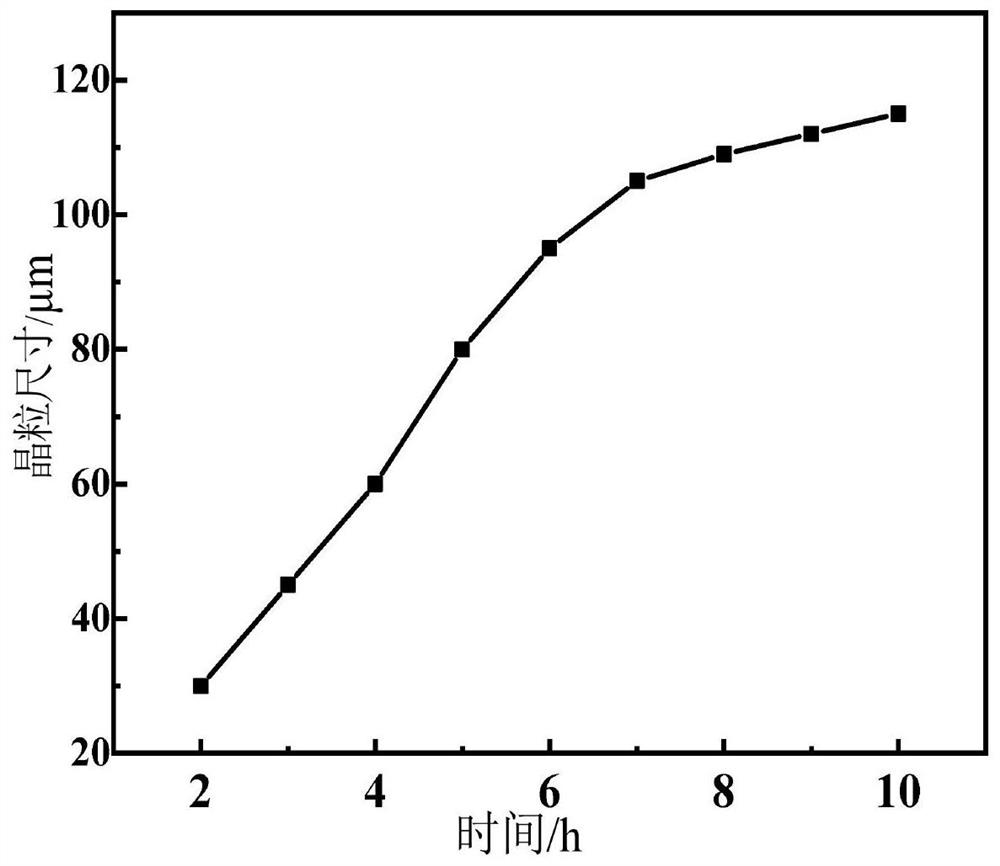

[0022] The present invention also provides a rare earth tantalate RE based on molten salt method 3 TaO 7 The preparation method of spherical powder, described method specifically comprises the following steps:

[0023] (1) The rare earth oxide RE 2 o 3 and tantalum pentoxide Ta 2 o 5 The raw materials are mixed with molten salt and deionized water in a ball mill tank, then zirconia balls are added and ball milled by a planetary ball mill until they are evenly mixed; the mixed powder is subjected to pressure filtration, drying and sieving in sequence before further processing calcined;

[0024] (2) Take out the powder after cooling to room temperature with the furnace, and wash the obtained product repeatedly with heated deionized water to remove excess chloride salt until the filtrate does not contain Cl - until;

[0025] (3) After the washed powder is filtered, dried and sieved, the rare earth tantalate RE with the required particle size can be obtained 3 TaO 7 Spher...

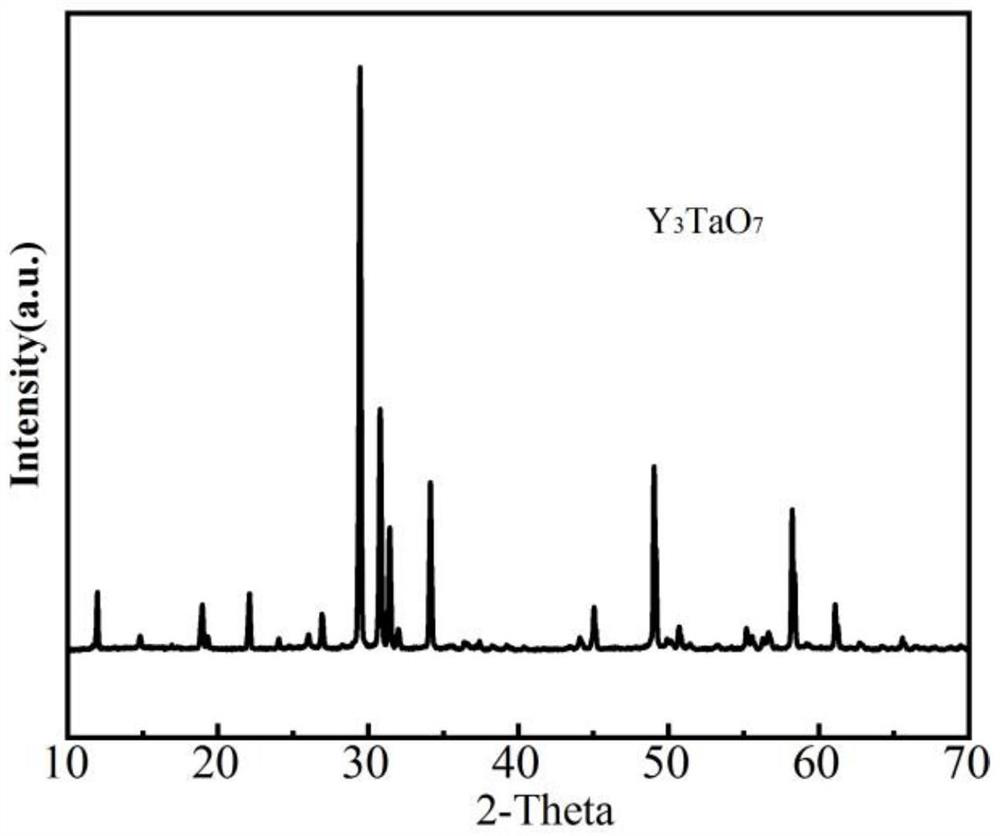

Embodiment 1

[0049] A kind of molten salt method described in this embodiment prepares rare earth tantalate Y 3 TaO 7 The method for spherical powder specifically comprises the following steps:

[0050] Weigh the raw material rare earth oxide Y at a molar ratio of 3:1 2 o 3 (6.774kg) and tantalum pentoxide Ta 2 o 5 (4.419kg) 11.193kg in total, weigh the mixed salt of KCl and NaCl according to the ratio of (1~6):(1~3), as shown in Table 1, weigh the raw material (11.193kg) and molten salt (55.965kg) according to 1:5 kg) into a ball milling tank, using deionized water as the medium, milling in a planetary ball mill for 12 hours (500r / min). Pass through a 400-mesh sieve for 24 hours, and then place it in a resistance furnace for calcination. The calcination temperature and calcination time are 800°C and 5h, respectively, and the heating rate is 5°C / min. , the resulting product was repeatedly washed several times with heated deionized water to remove excess chloride salts until the 3 ) ...

Embodiment 2

[0055] A kind of molten salt method described in this embodiment prepares rare earth tantalate Dy 3 TaO 7 The method for spherical powder specifically comprises the following steps:

[0056] Weigh the raw material rare earth oxide Dy at a molar ratio of 3:1 2 o 3 (11.19kg) and tantalum pentoxide Ta 2 o 5 (4.419kg) 15.609kg in total, weigh the mixed molten salt of KCl and NaCl according to the ratio of 6:1, weigh the raw materials and molten salt according to (1~2):(2~7) and pour them into the ball mill tank, as shown in Table 2 , using deionized water as the medium, ball milling in a planetary ball mill for 12 hours (500r / min), after the ball milling is completed, use a filter press to remove the water in the slurry, dry it at 90°C for 24 hours, and first pass through a 100-mesh sieve After that (take the sieve) and pass through a 400-mesh sieve (take the sieve), and then place it in a resistance furnace for calcination, the calcination temperature and calcination time ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com