Halogen-free flame-retardant thermoplastic elastomer

A thermoplastic elastomer and modification technology, applied in the field of halogen-free flame-retardant thermoplastic elastomers, can solve the problems of slow heat dissipation, high material selection requirements, and easy combustion, etc., to delay decomposition, reduce dielectric constant, good resistance The effect of flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

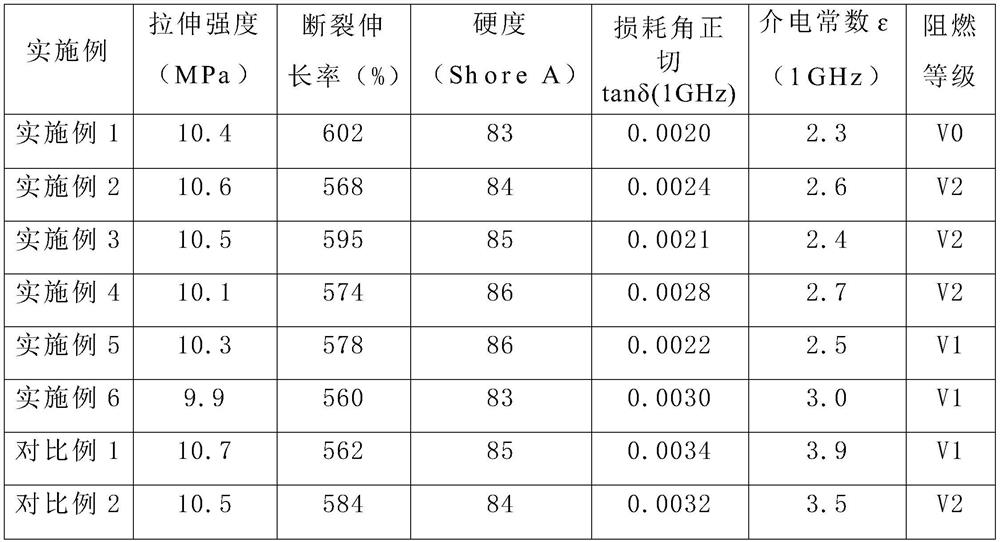

Examples

Embodiment 1

[0049] S1. After shearing the silica airgel and KH560 silane coupling agent with a concentration of 5wt%, put it into a water / ethanol mixed solution with a volume ratio of 1:1 and stir for 1 hour. After cleaning, dry at 80°C to prepare a ring Oxidized silica airgel. The mass ratio of silica airgel to KH560 silane coupling agent is 1:1.

[0050] S2. Put octasilsesquioxane and KH550 silane coupling agent with a concentration of 5wt% into a water / ethanol mixed solution with a volume ratio of 1:1 and stir for 5 hours. After cleaning, dry at 80°C to prepare aminated Silsesquioxane. The mass ratio of silsesquioxane to KH550 silane coupling agent is 1:1.

[0051] S3. Prepare 5 parts of epoxidized silica airgel and 10 parts of aminated silsesquioxane according to the parts by mass;

[0052] S4. React the epoxidized silica airgel and the aminated silsesquioxane at 80°C for 2 hours, and the rotating speed is 400rpm, and the POSS is covered on the modified dioxane through the reaction...

Embodiment 2

[0065] S1. After shearing the silica airgel and KH560 silane coupling agent with a concentration of 5wt%, put it into a water / ethanol mixed solution with a volume ratio of 1:1 and stir for 1 hour. After cleaning, dry at 80°C to prepare a ring Oxidized silica airgel. The mass ratio of silica airgel to KH560 silane coupling agent is 1:1.

[0066] S2. Put octasilsesquioxane and KH550 silane coupling agent with a concentration of 5wt% into a water / ethanol mixed solution with a volume ratio of 1:1 and stir for 5 hours. After cleaning, dry at 80°C to prepare aminated Silsesquioxane. The mass ratio of silsesquioxane to KH550 silane coupling agent is 1:1.

[0067] S3. Prepare 8 parts of epoxidized silica airgel and 5 parts of aminated silsesquioxane according to the parts by mass;

[0068] S4. React the epoxidized silica airgel and the aminated silsesquioxane at 80°C for 2 hours, and the rotating speed is 400rpm, and the POSS is covered on the modified dioxane through the reaction ...

Embodiment 3

[0081] S1. After shearing the silica airgel and KH560 silane coupling agent with a concentration of 5wt%, put it into a water / ethanol mixed solution with a volume ratio of 1:1 and stir for 1 hour. After cleaning, dry at 80°C to prepare a ring Oxidized silica airgel. The mass ratio of silica airgel to KH560 silane coupling agent is 1:1.

[0082] S2. Put octasilsesquioxane and KH550 silane coupling agent with a concentration of 5wt% into a water / ethanol mixed solution with a volume ratio of 1:1 and stir for 5 hours. After cleaning, dry at 80°C to prepare aminated Silsesquioxane. The mass ratio of silsesquioxane to KH550 silane coupling agent is 1:1.

[0083] S3. Prepare 10 parts of epoxidized silica airgel and 5 parts of aminated silsesquioxane according to the parts by mass;

[0084] S4. React the epoxidized silica airgel and the aminated silsesquioxane at 80°C for 2 hours, and the rotating speed is 400rpm, and the POSS is covered on the modified dioxane through the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com