A self-foaming multifunctional water-based moisture-absorbing coating and its preparation method

A multi-functional, self-foaming technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of high thermal conductivity, poor moisture absorption, high construction environment requirements, etc. Excellent moisture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

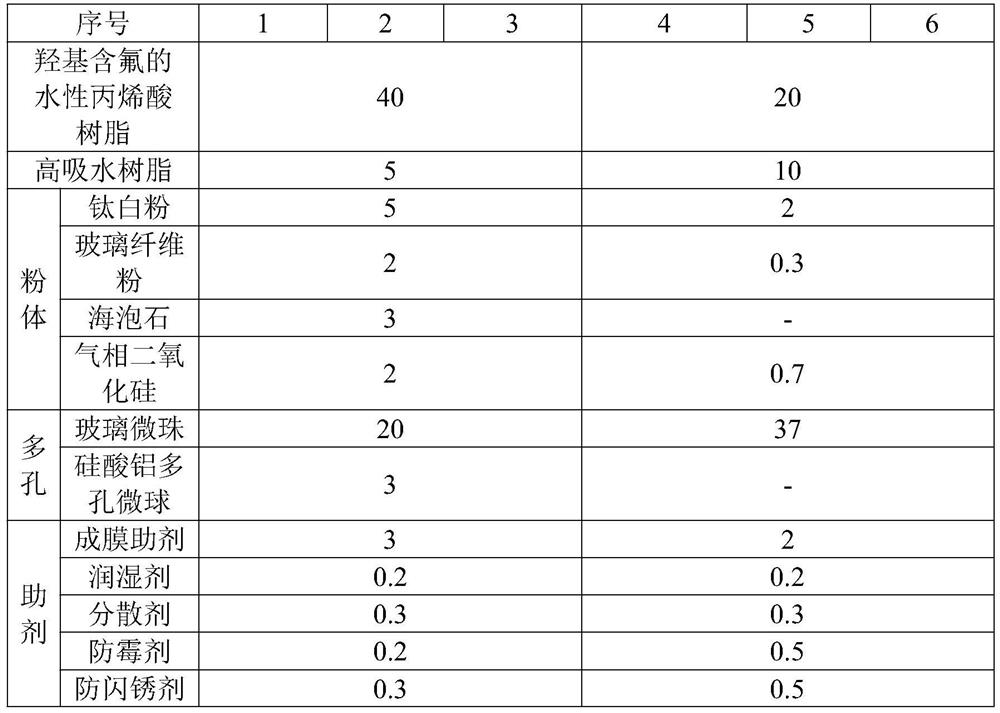

[0045] Embodiment 1, a kind of self-foaming multifunctional water-based moisture-absorbing paint of this embodiment is mixed by separately packaged component A and separately packaged component B when using; The mass ratio is 100:5 mixed;

[0046] Wherein, the component A is composed of 40 parts by mass of hydroxyl fluorine-containing water-based acrylic resin, 5 parts of superabsorbent resin, 12 parts of powder filler, 23 parts of porous material, 3 parts of film-forming aid, and 0.2 part of wetting agent. , 0.3 parts of dispersant, 0.2 parts of antifungal agent, 0.3 parts of anti-flash rust agent, 0.3 parts of antifreeze and thawing agent, and 15.7 parts of water; the powder filler is 5 parts of titanium dioxide, 2 parts of glass fiber powder, sea 3 parts of pumice, 2 parts of fumed silica; 20 parts of porous materials are glass microspheres, 3 parts of aluminum silicate porous microspheres; the water-based acrylic resin containing fluorine in the hydroxyl group has a solid ...

Embodiment 2

[0062] Embodiment 2, a kind of self-foaming multifunctional water-based moisture-absorbing coating of this embodiment is mixed by separately packaged component A and separately packaged component B when using; The mass ratio is 100:5 mixed;

[0063] Wherein, the component A is composed of 20 parts by mass of hydroxyl fluorine-containing water-based acrylic resin, 10 parts of superabsorbent resin, 3 parts of powder filler, 37 parts of glass microspheres, 2 parts of film-forming aid, and 0.2 parts of wetting agent. 0.3 parts of dispersant, 0.5 parts of antifungal agent, 0.5 parts of anti-flash rust agent, 0.5 parts of antifreeze and thawing agent, and 25 parts of water; the powder filler is 2 parts of titanium dioxide, 0.3 parts of glass fiber powder, 0.7 parts of fumed silica; the water-based acrylic resin containing fluorine in the hydroxyl group is an anionic aqueous dispersion with a solid content ≥ 50%, a fluorine content ≥ 10%, and a hydroxyl content ≥ 3%; the water absorp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com