A kind of preparation method of lead alloy surface anti-corrosion composite coating

A composite coating and lead alloy technology, applied in anodizing and other directions, can solve the problems of weak corrosion resistance of lead alloy components, weak bonding strength of lead alloy matrix, and non-dense oxide film, achieving excellent corrosion resistance and saving time. Uniform effect with production cost, composite coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

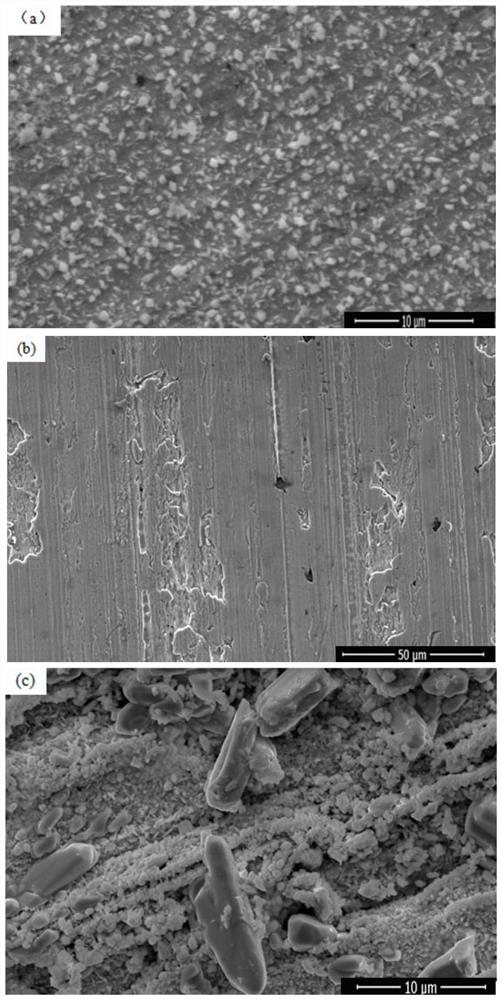

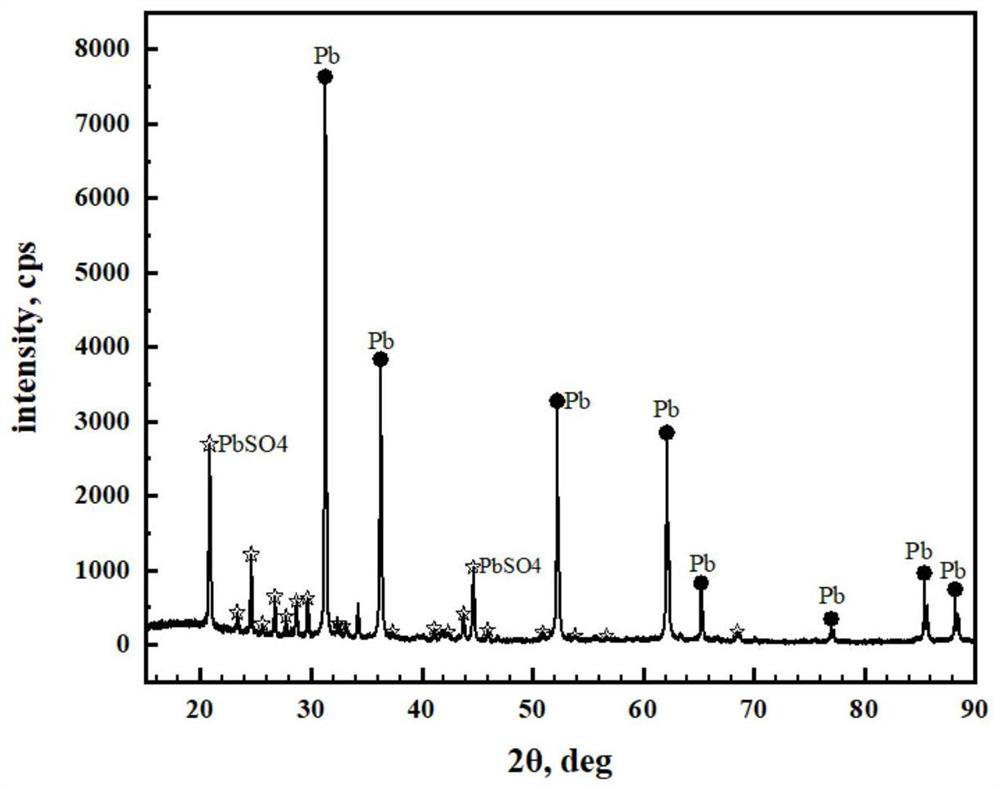

[0034] The sample is lead alloy, and its specific operation steps are as follows:

[0035] (1) Acetone degreasing: Place the polished lead alloy substrate in an acetone solution to remove oil at room temperature for 3 minutes.

[0036] (2) Acidification: Place the polished sample in a 5 ml / L sulfuric acid solution at room temperature for 3 min to remove the oxide and rust layer on the surface of the sample.

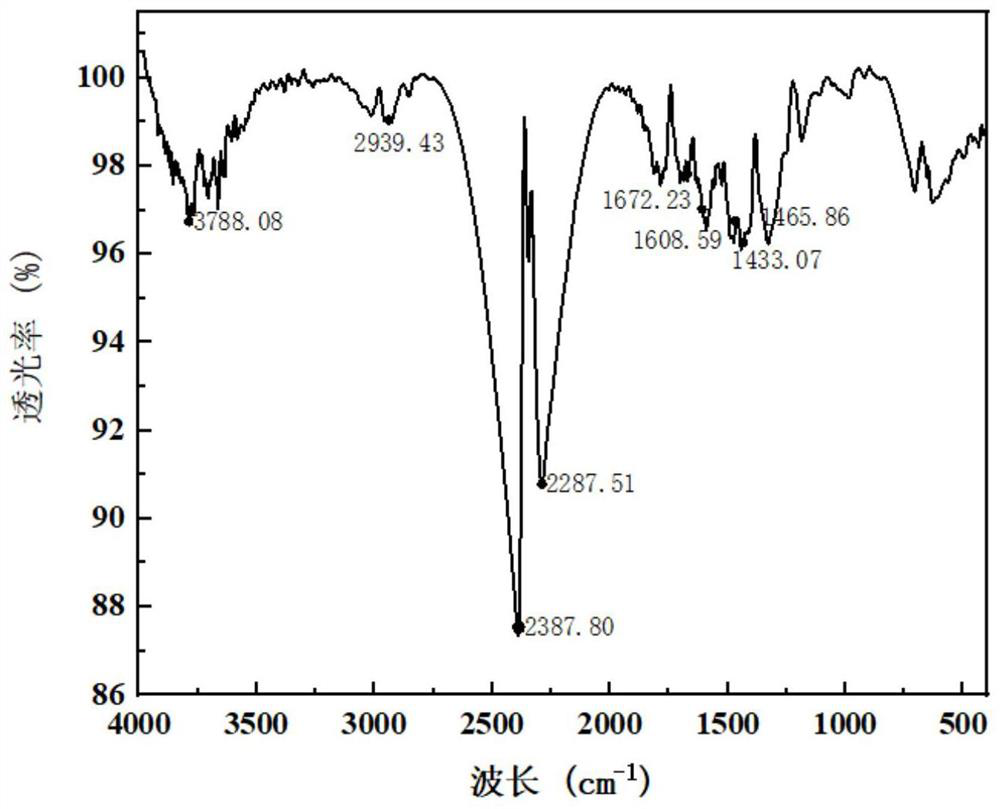

[0037] (3) Electrodeposition composite coating: the acid-washed lead alloy is used as the working electrode, the platinum sheet is used as the counter electrode, and the calomel electrode is used as the reference electrode.

[0038] Electrodeposition aqueous solution: 10mmol / L cerium ammonium sulfate ((NH 4 ) 4 Ce(SO 4 ) 4 ), 2g / L polyvinylpyrrolidone (PVP K30 ), 4mol / L sulfuric acid H 2 SO 4 of the mixture.

[0039] Electrolyte temperature: room temperature.

[0040] Electrodeposition parameters: the number of scanning cycles is 200, the potential range is -0.5 ...

Embodiment 2

[0042] The sample is lead alloy, and its specific operation steps are as follows:

[0043] (1) Acetone degreasing; place the polished lead alloy substrate in an acetone solution to remove oil at room temperature for 5 minutes.

[0044] (2) Acidification: Immerse the polished sample in 8 ml / L sulfuric acid solution for 5 min to remove the oxide and rust layer on the surface of the sample.

[0045] (3) Electrodeposition composite coating: the acid-washed lead alloy is used as the working electrode, the platinum sheet is used as the counter electrode, and the calomel electrode is used as the reference electrode.

[0046] Electrodeposition aqueous solution: 10mmol / L cerium ammonium sulfate ((NH 4 ) 4 Ce(SO 4 ) 4 ), 2g / L polyvinylpyrrolidone (PVP K30 ), 5mol / L sulfuric acid H 2 SO 4 of the mixture.

[0047] Electrolyte temperature: 30℃.

[0048] Electrodeposition parameters: the number of scanning cycles is 250, the potential range is -0.9 ~ 1.5V, the deposition time is 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com