Application of lithium lanthanum zirconium tantalum oxide as electrolyte material of solid oxide fuel cell

A solid oxide, electrolyte material technology, applied in fuel cells, circuits, electrical components, etc., can solve the problem of high operating temperature and achieve the effect of good output power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

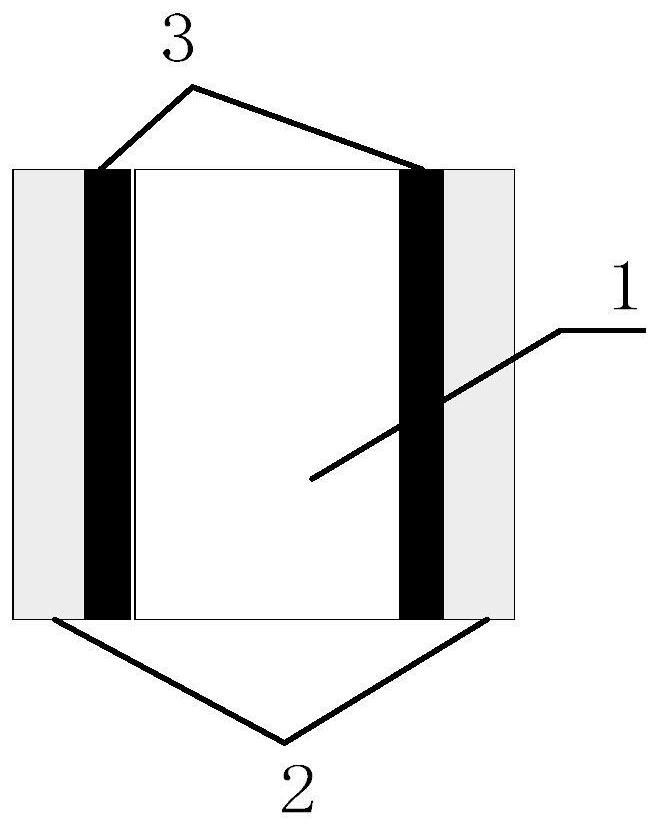

[0022] Such as figure 1 As shown, the structure of the fuel cell of the present invention is nickel foam-NCAL / LLZTO / NCAL-nickel foam. Among them, the cathode and anode materials are coated with NCAL3 on nickel foam 2, and the electrolyte material 1 is LLZTO (Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 ). Among them, the chemical formula of NCAL is: Ni 0.8 co 0.15 al 0.05 LiO 2-δ , NCAL can be purchased commercially directly. The electrolyte material LLZTO can also be purchased directly commercially.

[0023] The preparation method of foamed nickel-NCAL is: mix 10 grams of NCAL powder with 5mL terpineol to obtain a mixed material; add an adhesive polyvinylidene fluoride with a mass ratio of the mixed material of 5% to the mixed material, and fully grind to obtain a slurry material; the slurry is evenly coated on the foamed nickel to obtain the foamed nickel-NCAL.

[0024] Among them, the preparation method of the fuel cell is: the prepared anode and cathode foam nickel-NCAL and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com