Slow-resilience polyurethane foamed pillow containing plant flower and grass powder, and preparation method thereof

A technology of slow rebound and polyurethane, which is applied in the field of slow rebound polyurethane foam, which can solve problems such as pollution, reduce density, and increase the fragrance retention time of the foam body, so as to reduce the density, enhance the anti-decolorization ability, and increase the fragrance retention of the foam body. the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of the flower powder is as follows: drying the flowers and plants at 55° C. in isolation from the air, and pulverizing them into a powder with a particle diameter of 400 meshes to obtain the flower powder.

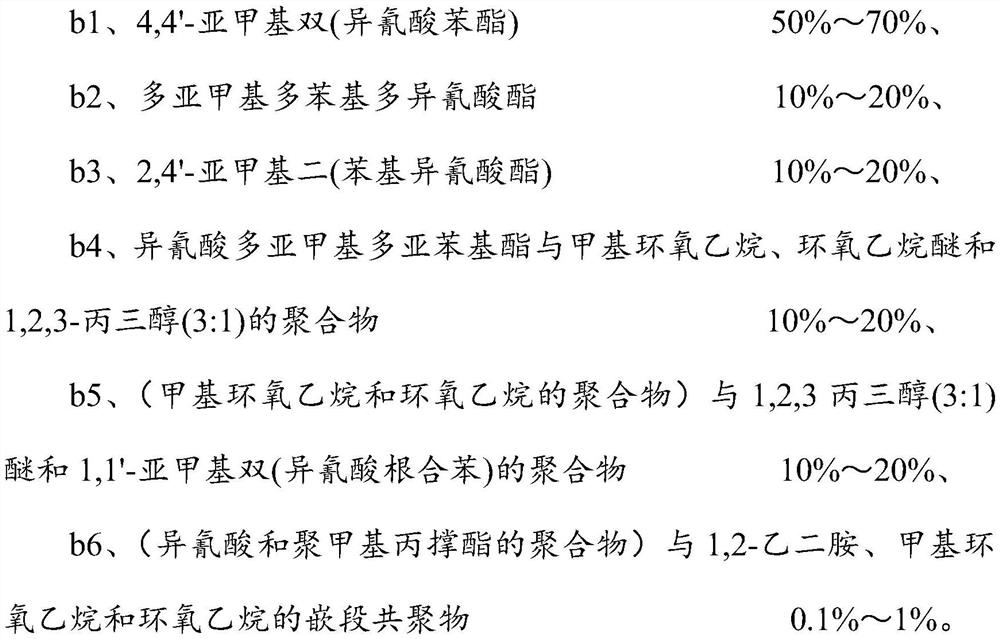

[0049] b1: 4,4'-methylenebis(phenylisocyanate), CAS#101-68-8;

[0050] b2: Polymethylene polyphenyl polyisocyanate, CAS#9016-87-9;

[0051] b3: 2,4'-methylenebis(phenylisocyanate), CAS#5873-54-1;

[0052] b4: Polymethylenepolyphenylene isocyanate, polymer with methyloxirane, oxirane ether and 1,2,3-propanetriol (3:1), CAS#58228- 05-0;

[0053] b5: (polymer of methyloxirane and oxirane) with 1,2,3 glycerol (3:1) ether and 1,1'-methylenebis(isocyanatobenzene) polymers, CAS#112898-48-3;

[0054] b6: (polymer of isocyanic acid and polymethylpropylene ester) block copolymer with 1,2-ethylenediamine, methyloxirane and ethylene oxide, CAS#312597-92-5 ;

[0055] Component B can be selected from Dongguan Shengda New Material Co., Ltd. For MDI iso...

Embodiment 1

[0066] This embodiment provides a slow-rebound polyurethane foam pillow containing rose pollen as a filler, which consists of component A and component B.

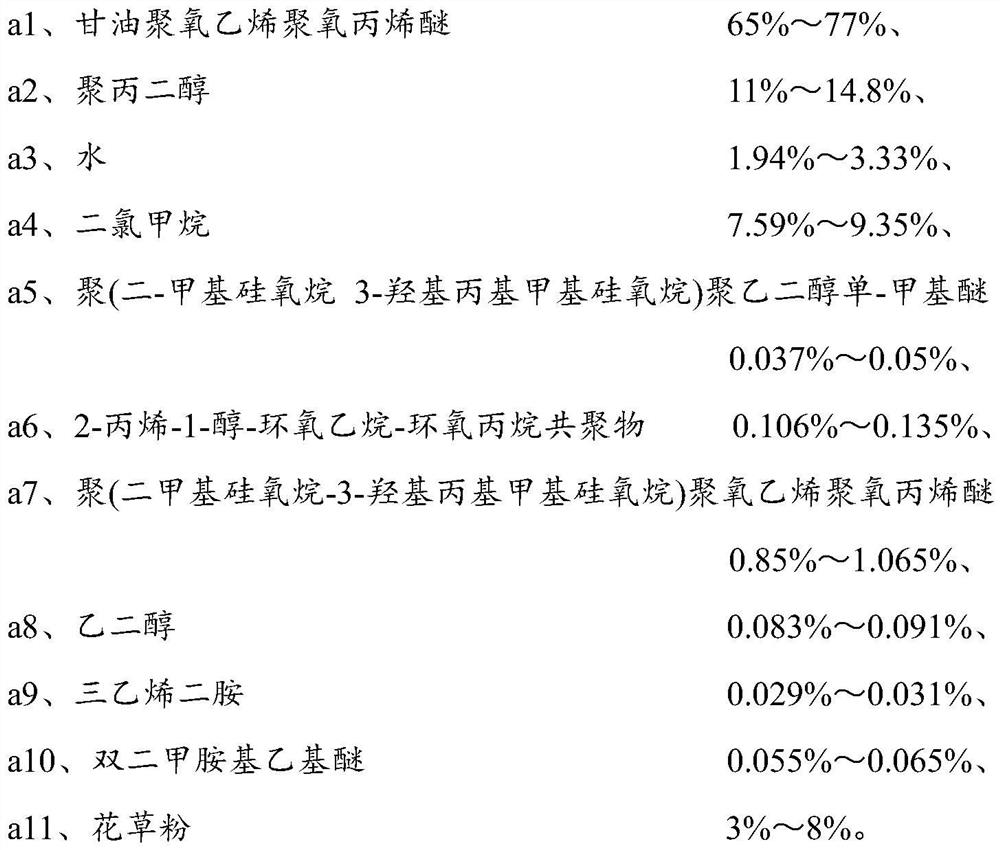

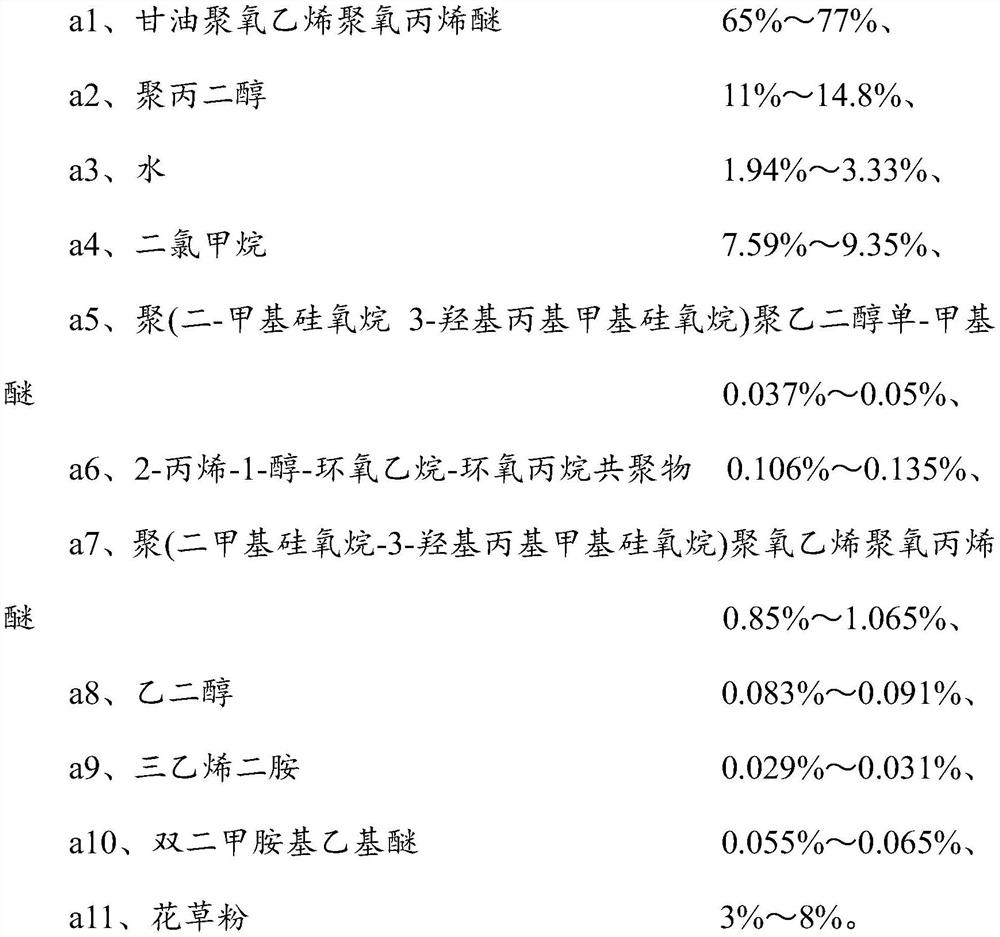

[0067] Wherein, A component is made up of the raw material of following content:

[0068]

[0069]

[0070] Component B is MDI prepolymer, which is manufactured by Dongguan Shengda New Material Co., Ltd. MDI isocyanate.

[0071] The preparation method of this slow resilience polyurethane foam pillow comprises the following preparation steps:

[0072] Step (1): Mix a1, a2, a3, a4, a5, a6, a7, a8, a9, a10 in component A in proportion, and disperse with a homogeneous mixing tank at 30°C at a speed of 180 revolutions per minute Completely, the pressure is normal pressure, and the dispersion liquid is obtained;

[0073] Step (2): Dry a11 in component A at 80°C, add it to the dispersion in step (1) and disperse completely at a speed of 180 revolutions per minute under normal pressure to obtain component A;

[0074] St...

Embodiment 2

[0078] This embodiment provides a slow rebound polyurethane foam pillow containing lotus leaf powder as a filler, which consists of component A and component B.

[0079] Wherein, A component is made up of the raw material of following content:

[0080]

[0081] Component B is MDI prepolymer, which is manufactured by Dongguan Shengda New Material Co., Ltd. MDI isocyanate.

[0082] The preparation method of the slow-rebound polyurethane foam pillow has the same specific preparation steps as in Example 1, so it will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com