Bio-ink for 3D printing of cornea repair material, preparation method of bio-ink and preparation method of cornea repair material

A bio-ink and repair material technology, applied in tissue regeneration, additive processing, prosthesis, etc., can solve problems such as difficult printing, and achieve the effect of short time-consuming, high-throughput printing, and improved biological performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

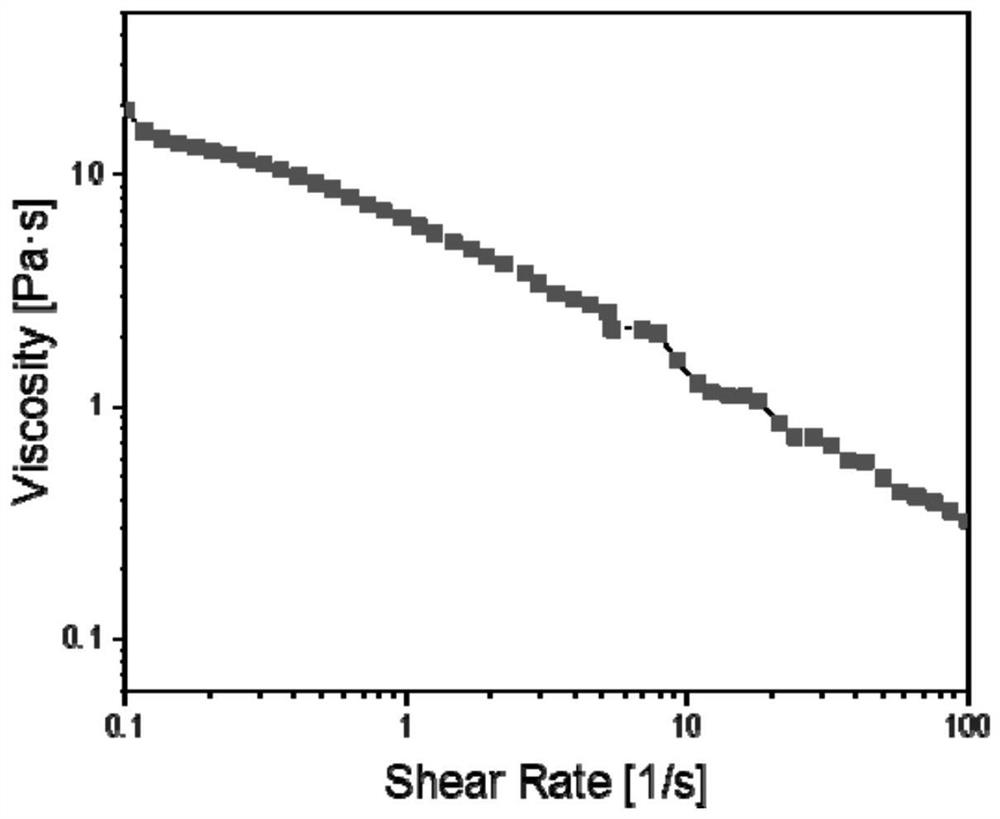

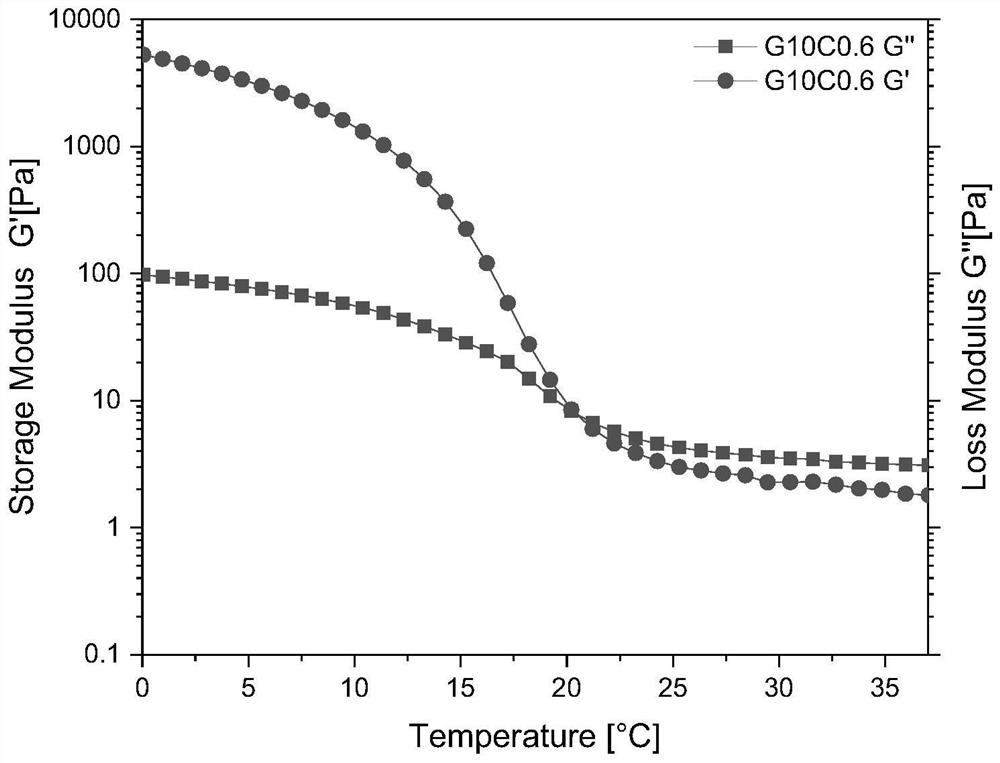

[0059] The bio-ink based on the 3D printing corneal repair material of the present embodiment includes methacrylamide-based gelatin, photoinitiator, collagen and solvent; in the present embodiment, the mass concentration of the methacrylamide-based gelatin in the bio-ink 100mg / mL; the mass concentration of the photoinitiator in the bioink is 5mg / mL; the mass concentration of the collagen in the bioink is 6.0mg / mL.

[0060] In the present embodiment, the grafting ratio of methacrylamide-based gelatin is 99%; the collagen is type I collagen extracted from bovine Achilles tendon; the photoinitiator is I2959 (2-hydroxyl-2-methyl-1-[ 4-(2-hydroxyethoxy)phenyl]-1-propanone); solvents include PBS and hydrochloric acid solution.

[0061] The preparation method of the bio-ink based on the 3D printing corneal repair material of the present embodiment is:

[0062] (1) GelMA freeze-dried solid with a grafting rate of 99% was dissolved in 1XPBS at 50° C. to prepare a GelMA solution with a...

Embodiment 2

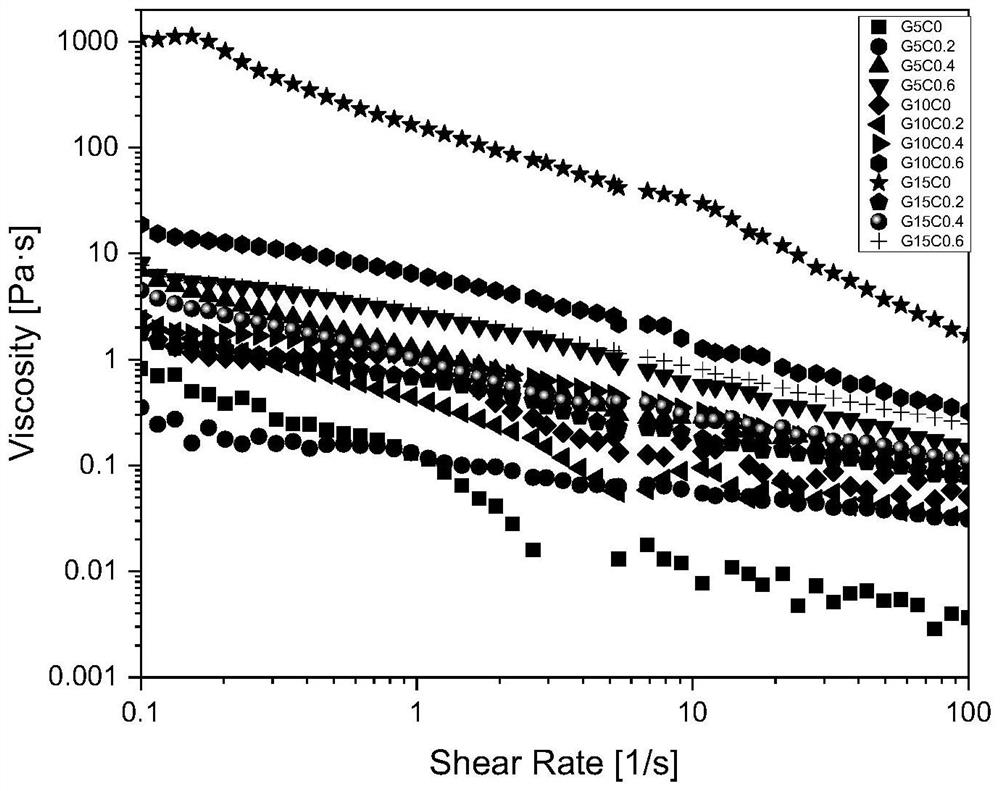

[0069] The bio-ink based on the 3D printing corneal repair material of the present embodiment includes methacrylamide-based gelatin, photoinitiator, collagen and solvent; in the present embodiment, the mass concentration of the photoinitiator in the bio-ink is 5mg / mL; the mass concentration of the methacrylamide-based gelatin in the bio-ink is A mg / mL; the concentration of the collagen in the bio-ink is B mg / mL; the specific formula is shown in Table 1.

[0070] In this embodiment, the grafting rate of methacrylamide-based gelatin is 99%; the collagen is type I collagen extracted from bovine Achilles tendon; the photoinitiator is I2959; the solvent includes PBS and hydrochloric acid solution.

[0071] The preparation method of the bio-ink based on the 3D printing corneal repair material of the present embodiment is:

[0072] The GelMA freeze-dried solid with a grafting rate of 99% was dissolved in 1XPBS at 50° C. to prepare a GelMA solution with a mass concentration of Amg / mL...

Embodiment 3

[0081] Utilize the bio-ink prepared in embodiment 1 to realize the preparation method of corneal repair material, the steps are as follows:

[0082] (1) The bio-ink is placed in a low-temperature light-proof barrel for 3D printing. Set the temperature of the printer barrel to 30°C, the temperature of the printing platform to 10°C, the printing pressure to 0.035MPa, and the printing speed to 6mm / s. The ink is extruded onto the temperature-controlled cornea printing platform;

[0083] (2) Set the UV light intensity to 100mW / cm 2 , the printing speed is 8mm / s.

[0084] (3) Remove the corneal stent from the printing platform with tweezers to obtain the 3D printed corneal repair material of the present invention.

[0085] Specifically, this embodiment adopts such as Figure 5 The temperature-controlled cornea printing platform with the structure shown: the temperature-controlled cornea printing platform is provided with a plurality of bosses with circular cross-sections; the cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com