Molybdenum disulfide nanosheet with folds as well as preparation method and application of molybdenum disulfide nanosheet

A molybdenum disulfide and nanosheet technology, applied in molybdenum sulfide, chemical instruments and methods, hydrocarbon production from oxygen-containing organic compounds, etc., can solve the problem of extremely limited activity of granular molybdenum sulfide, and achieve simple and fast processes and raw materials. Inexpensive and accessible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A kind of preparation method of the molybdenum disulfide nanoplate with wrinkle of the present invention, comprises the steps:

[0028] 1. The commercially purchased granular molybdenum disulfide is intercalated with n-butyllithium / n-hexane solution to carry out interlayer exfoliation of molybdenum disulfide to obtain single-layer or less-layer molybdenum disulfide nanosheets; The particle size of molybdenum sulfide is 325-500 mesh; the molar ratio of molybdenum disulfide to n-butyllithium is 1: (3.5-6); the intercalation step requires one or more auxiliary processes such as constant temperature stirring, constant temperature oscillation, and ultrasound , to facilitate intercalation and interlayer stripping;

[0029] 2. Ultrasonic disperse the single-layer or few-layer molybdenum disulfide nanosheets obtained in step 1 into a strong polar organic solvent, such as propylene carbonate, N-methylpyrrolidone or N,N-dimethylformamide or Two or more, until the mixture is unif...

Embodiment 1

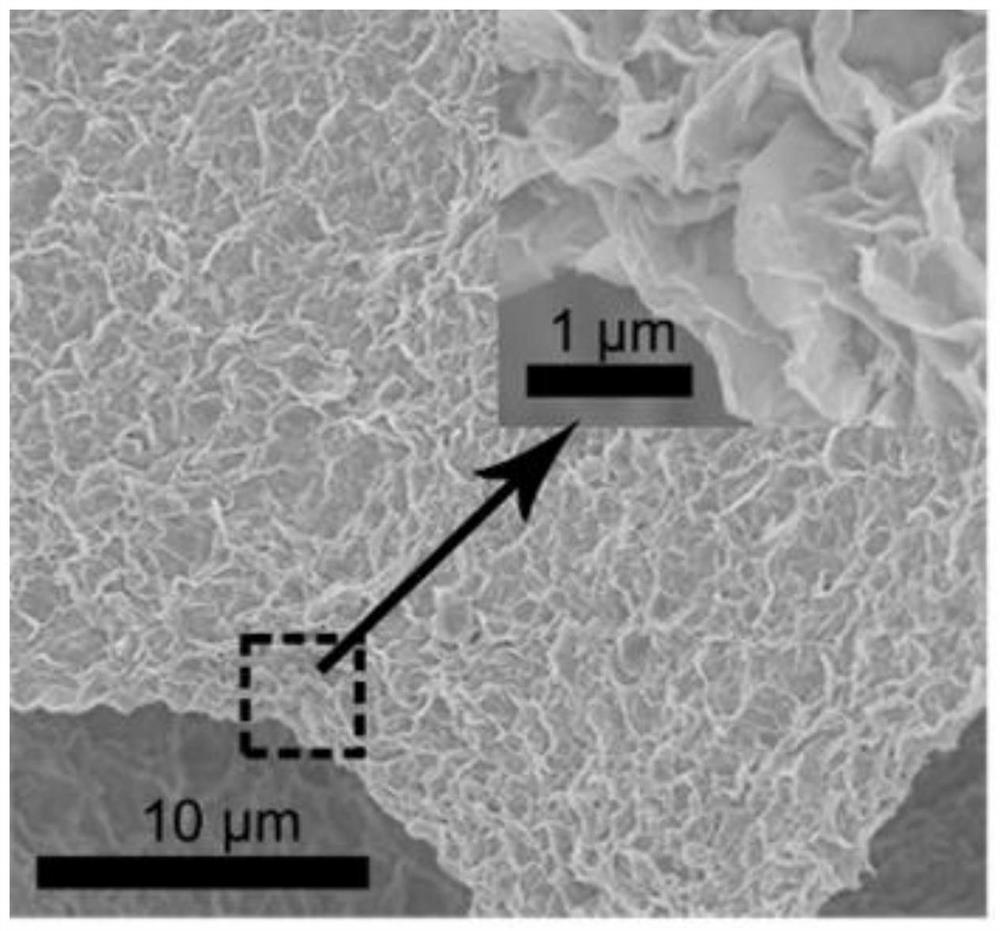

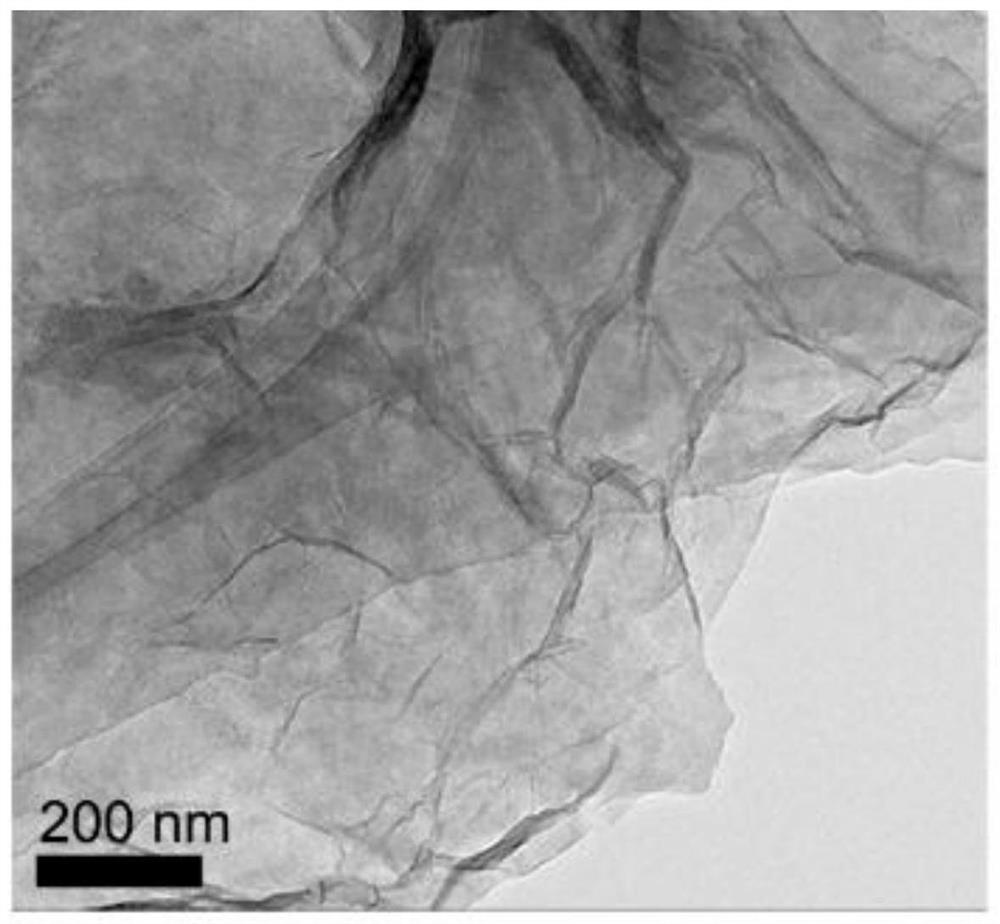

[0033] Example 1: Preparation of molybdenum disulfide nanosheets with abundant folds

[0034] Step 1: Take commercial molybdenum disulfide particles with a particle size of 400 mesh and add them to 20 mL of 2.5M n-butyllithium / n-hexane solution under an inert atmosphere (such as nitrogen), sonicate for 3 hours at room temperature, wash with n-hexane and water , to obtain molybdenum disulfide nanosheets with a single layer or a few layers;

[0035] Step 2: Get 1g of molybdenum disulfide nanosheets obtained in step 1 and add them to 1L of propylene carbonate, and ultrasonically disperse them for 30 minutes, so that the molybdenum disulfide nanosheets are uniformly dispersed in propylene carbonate, and the organic molybdenum disulfide nanosheets are obtained. Dispersions;

[0036] Step 3: Take 30mL of the organic dispersion of molybdenum disulfide nanosheets obtained in step 2, and treat it with microwave irradiation for 8 minutes. The power during microwave treatment is 500W, a...

Embodiment 2

[0039] Example 2: Preparation of molybdenum disulfide nanosheets with abundant folds

[0040] Step 1: Take commercial molybdenum disulfide particles with a particle size of 325 mesh and add them to 15mL of 2.5M n-butyllithium / n-hexane solution under an inert atmosphere, stir at 60°C for 3 days, wash with n-hexane and water to obtain Molybdenum disulfide nanosheets with single or few layers;

[0041] Step 2: Add 500 mg of molybdenum disulfide nanosheets obtained in step 1 into 250 mL of N,N-dimethylformyl, and ultrasonically disperse for 30 minutes to make the molybdenum disulfide nanosheets in N,N-dimethylformyl uniformly dispersed in the medium to obtain an organic dispersion of molybdenum disulfide nanosheets;

[0042] Step 3: Take 30mL of the molybdenum disulfide nanosheet organic dispersion obtained in step 2, and treat it with microwave irradiation for 15 minutes. The power during microwave treatment is 800W, and the microwave frequency is 2.45GHz; stir at the same time,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com