Preparation method of bis (N-methylbenzamide) ethoxymethylsilane

A technology of ethoxymethylsilane and methylbenzamide is applied in the field of preparation of diethoxymethylsilane, can solve the problems of difficult separation and purification, high production energy consumption, low production energy consumption and the like, and achieves atomic The effect of high utilization rate, low production energy consumption and three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

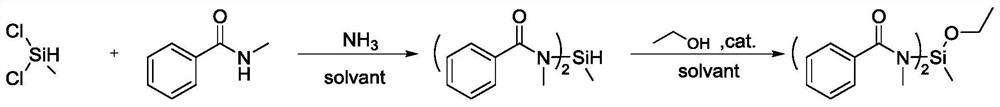

[0026] A kind of preparation method of two (N-methylbenzamide) ethoxymethylsilane, reaction equation is as figure 1 shown, including the following steps:

[0027] A. Add N-methylbenzamide solution with 2~2.3 times the molar weight of methyl dichlorosilane into the glass-lined kettle, heat to 60~120℃, and feed 2~2.4 times the molar weight of methyl dichlorosilane Double the ammonia gas circulation, drop methyl dichlorosilane to react, react for 1~3h, and get the intermediate product bis(N-methylbenzamide) methylhydrogensilane;

[0028] B. Control the temperature in the kettle to 40~80°C, close the ammonia gas circulation, empty the tail gas, add a nickel chloride catalyst to the intermediate product system of step A, add ethanol in an equimolar amount to methyl dichlorosilane to continue the reaction, and keep Keep the pressure in the kettle constant, continue to react for 3~5h, filter the reaction solution, and vacuum distill the filtrate to separate the solvent to obtain bis...

Embodiment 1

[0030] A. Add 1000kg of N-methylbenzamide into a 3000L glass-lined kettle, add 1000L of toluene, replace the nitrogen, stir and heat to 60°C, feed 120kg of ammonia gas at a rate of 12.2kg / hr, and start the ammonia gas cycle Machine circulation, drip methyl dichlorosilane 380kg reaction with the speed of 40kg / h, dropwise complete reaction 3h, obtain intermediate product bis(N-methylbenzamide) methylhydrogensilane;

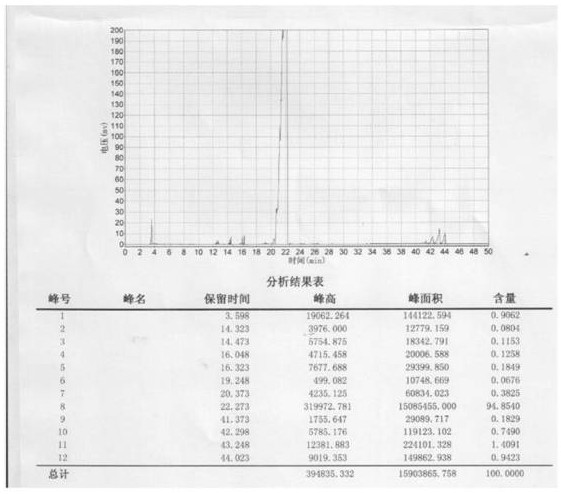

[0031] B. Control the temperature in the kettle to 50°C, turn off the ammonia gas circulation, empty the tail gas, add 100g of nickel chloride catalyst to the intermediate product system of step A, add 153kg of ethanol dropwise to continue the reaction, keep the constant pressure in the kettle, continue the reaction for 5h and then filter Reaction solution, filter residue is exported, and filtrate vacuum distillation is separated petroleum ether, obtains two (N-methylbenzamide) ethoxymethylsilanes of 1130kg, by figure 2 It can be seen that the integral ratio of pro...

Embodiment 2

[0033] A. Add 1000kg of N-methylbenzamide into a 3000L glass-lined kettle, add 1000L of 120# petroleum ether, replace nitrogen, stir and heat to 120°C, feed 120kg of ammonia gas at a speed of 12.2kg / hr, and start Ammonia circulator circulates, drips 380 kg of methyl dichlorosilane at a rate of 40 kg / h for reaction, and reacts for 1 hour after the dropwise addition to obtain the intermediate product bis(N-methylbenzamide) methylhydrogen silane;

[0034] B. Control the temperature in the kettle to 80°C, turn off the ammonia gas circulation, empty the tail gas, add 100g of nickel chloride catalyst to the intermediate product system of step A, add 153kg of ethanol dropwise to continue the reaction, keep the constant pressure in the kettle, continue the reaction for 3 hours and then filter The reaction solution and the filter residue were transported outside, and the filtrate was vacuum distilled to separate petroleum ether to obtain 1135 kg of bis(N-methylbenzamide)ethoxymethylsila...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap