Photosensitive polymer as well as preparation method and application thereof

A polymer, photosensitive technology, applied in the direction of photosensitive materials used in optomechanical equipment, can solve the problems of poor wettability, poor compatibility, narrow application range, etc., and achieve the effect of good wettability and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

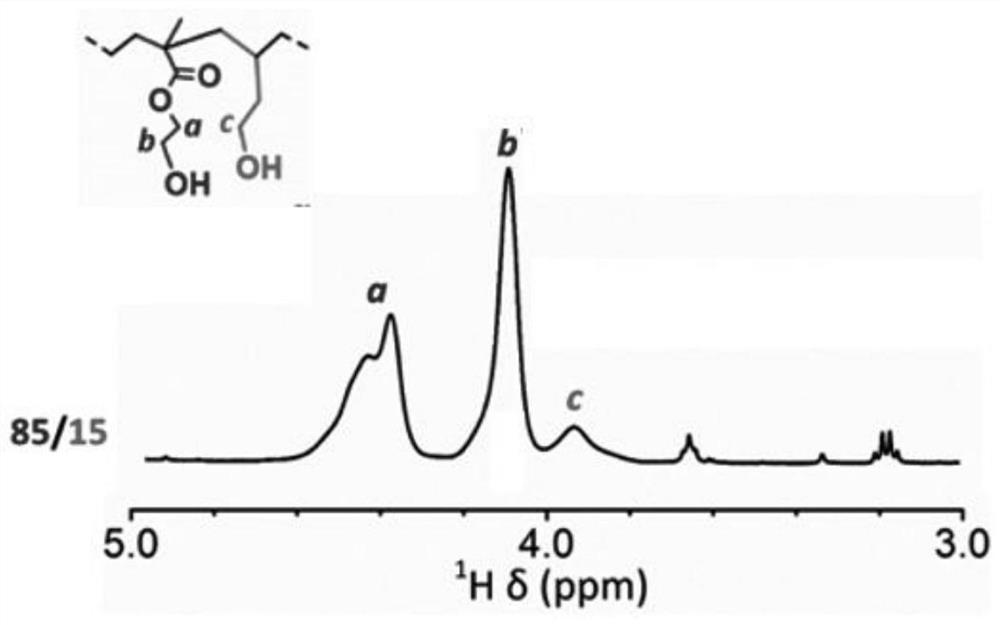

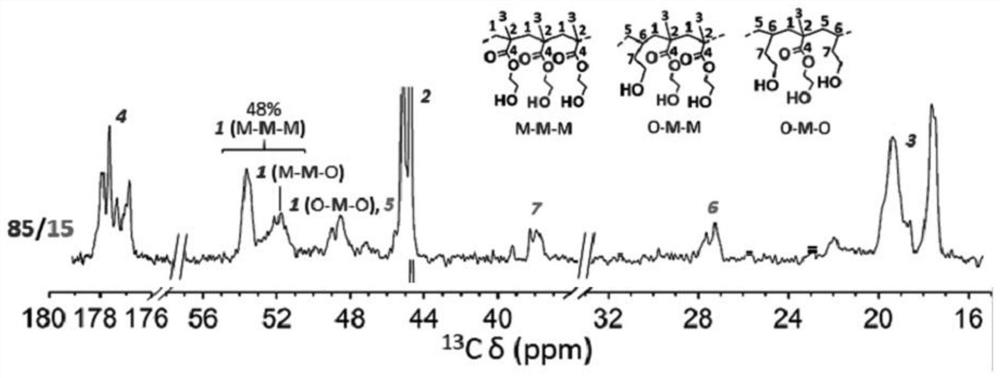

[0085] A photosensitive polymer prepared from monomers shown in the following formula:

[0086]

[0087] The preparation process of the photosensitive polymer is as follows: 30g of monomer M1, 15g of monomer M2 and 15g of monomer M3 were dissolved in 70mL of acetonitrile and transferred to the reaction flask, the temperature of the mixed liquid system was raised to 90°C, and 0.20g of supernatant was added Dibenzoyl peroxide (BPO) was oxidized, mixed evenly, the temperature of the reaction system was increased to 100°C, the reaction was continued for 8 hours, 5mL of ethanol was added to terminate the reaction, and the mixed solution after the reaction was terminated was precipitated in ethanol, and the obtained solid was in Heat and dry in an oven at 100° C. for 8 hours to obtain 152.1 g of white powdery photosensitive polymer Q.

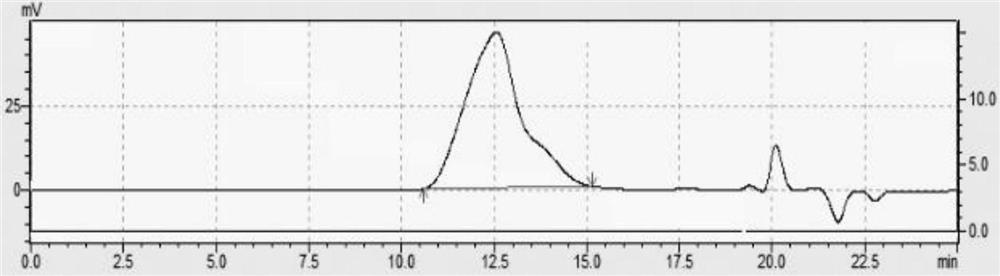

[0088] Adopt gel permeation chromatography (Gel permeation chromatography, GPC) to measure the number average molecular weight of photosensitive ...

Embodiment 2

[0103] A kind of ArFi photoresist, comprises the photosensitive polymer Q1 of 25g embodiment 1 preparations, 0.2g photosensitive acid generator P2, 0.05g acid diffusion stopper P3 and 0.01g surfactant P4, wherein, P2 contains components as 0.02g P2a, 0.05g P2b, 0.03g P2c and 0.1g P2d, P3 contains components of 0.01g P3a, 0.05g P3b, 0.04g P3c.

[0104] The structural formulas of P2a-P2d are as follows:

[0105]

[0106] The structural formulas of P3a-P3c are as follows:

[0107]

[0108] The structural formula of P4 is as follows:

[0109]

[0110] Prepare ArFi photoresist, the specific operation steps are as follows:

[0111] Take 25g of the photosensitive polymer Q1 prepared in Example 1, adjust its contact angle from 87° to 24° by acid treatment, and dissolve it in ethyl lactate (ethyl lactate, EL) until the polymer concentration is about 5% mass concentration Then add 0.2g of photosensitive acid generator P2, 0.05g of acid diffusion terminator P3 and 0.01g of su...

Embodiment 3

[0123] An ArFi photoresist, including 25g of photosensitive polymer Q4 prepared in Example 1, 0.15g of photosensitive acid generator P2', 0.05g of acid diffusion terminator P3' and 0.01g of surfactant P4'. Among them, P2 contains 0.02g P2a', 0.05g P2b', 0.03g P2c', and P3 contains 0.01g P3a', 0.01g P3b', 0.03g P3c'.

[0124] The structural formula of P2a'-P2c' is as follows:

[0125]

[0126] The structural formula of P3a'-P3c' is as follows:

[0127]

[0128] The structural formula of P4' is as follows:

[0129]

[0130] The preparation method of ArFi photoresist, concrete operation steps are as follows:

[0131] Take 25g of the photosensitive polymer Q4 prepared in Example 1, adjust its contact angle from 114° to 36° by acid treatment, and dissolve it in ethyl lactate (ethyl lactate, EL) until the polymer concentration is about 5% mass concentration Then add 0.15g of photosensitive acid generator P2', 0.05g of acid diffusion terminator P3' and 0.01g of surfactant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com