Preparation method of aromatic diamine modified graphene oxide epoxy resin coating

A graphene epoxy resin and aromatic diamine technology, applied in the field of preparation of aromatic diamine modified graphene oxide epoxy resin coatings, can solve the problems of weak non-covalent bond stability, poor graphene oxide structural stability and the like , to achieve the effect of convenient industrial production, low cost, and solving agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

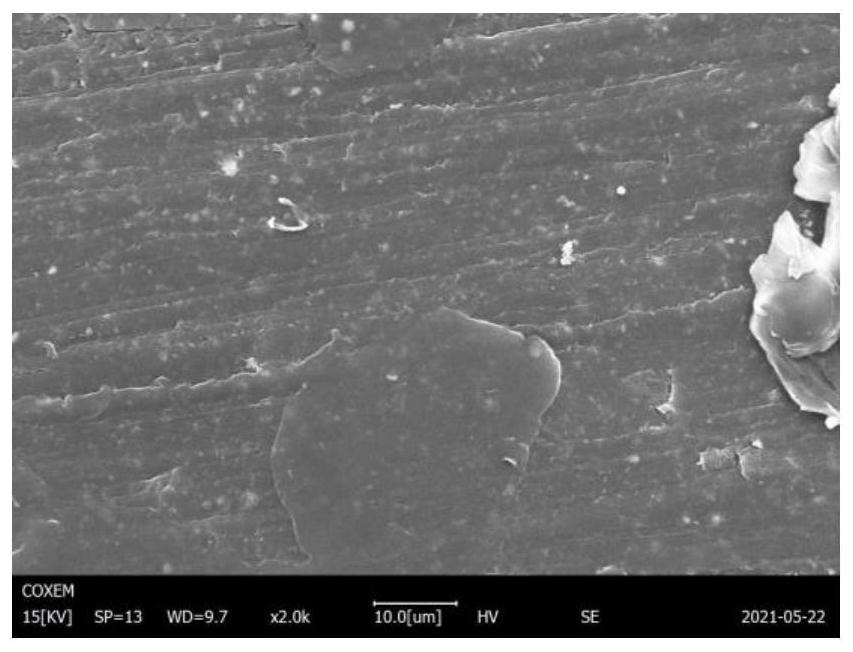

[0032] see Figure 1 to Figure 4 , the technical solution provided by the present invention is the preparation of p-phenylenediamine-modified graphene oxide powder: small pieces of graphene oxide are prepared by an improved Hummers method, and a 1 mg / mL graphene oxide aqueous dispersion is prepared. Add 1.014g p-phenylenediamine to 200mL graphene oxide aqueous dispersion, adjust the pH value of the solution to 11, and react at 70°C for 6h. After the reaction, the reaction product was washed with deionized water several times until a colorless and transparent raffinate was obtained. Finally, the product was uniformly dispersed by ultrasonic, and vacuum freeze-dried to obtain p-phenylenediamine-modified graphene oxide powder.

[0033] Preparation of composite epoxy coating: Weigh 1.275g of p-phenylenediamine-modified graphene oxide powder and ultrasonically disperse it in 498.725g of deionized water to obtain a p-phenylenediamine-modified graphene oxide aqueous dispersion. 300...

Embodiment 2

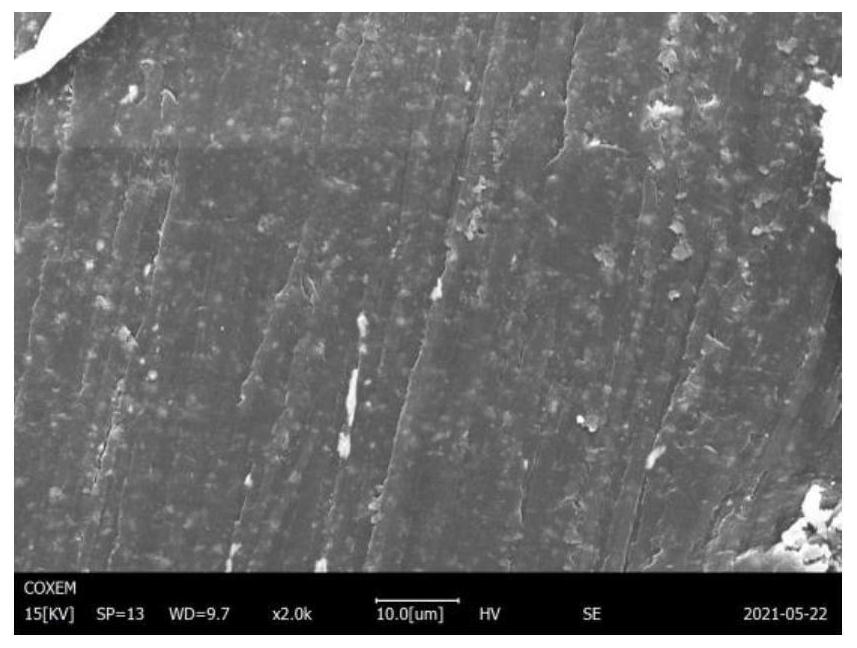

[0036]Preparation of o-phenylenediamine-modified graphene oxide powder: small pieces of graphene oxide were prepared by the improved Hummers method, and a 1 mg / mL graphene oxide aqueous dispersion was prepared. Add 0.5576g o-phenylenediamine into 200mL graphene oxide aqueous dispersion, adjust the pH value of the solution to 10, and react at 65°C for 6h. After the reaction, the reaction product was washed with deionized water several times until a colorless and transparent raffinate was obtained. Finally, the product was uniformly dispersed by ultrasonic, and vacuum freeze-dried to obtain o-phenylenediamine-modified graphene oxide powder.

[0037] Preparation of composite epoxy coating: Weigh 1.7 g of o-phenylenediamine-modified graphene oxide powder, and ultrasonically disperse it in 498.3 g of deionized water to obtain an aqueous dispersion of o-phenylenediamine-modified graphene oxide. 300g of emulsion, 500g of o-phenylenediamine-modified graphene oxide aqueous dispersion ...

Embodiment 3

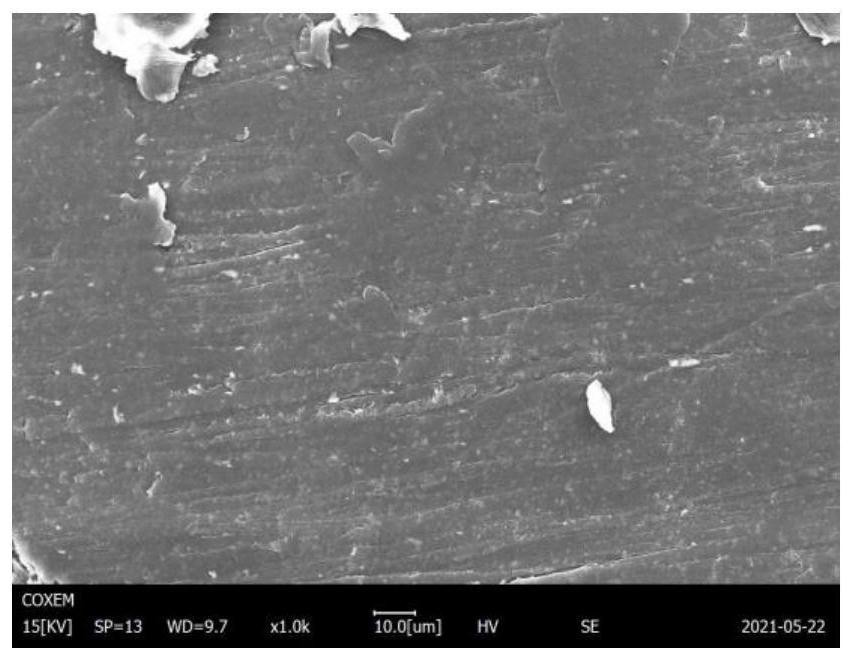

[0040] Preparation of m-phenylenediamine-modified graphene oxide powder: small pieces of graphene oxide were prepared by the improved Hummers method, and a 1 mg / mL graphene oxide aqueous dispersion was prepared. Add 0.5068g m-phenylenediamine into 200mL graphene oxide aqueous dispersion, adjust the pH value of the solution to 11, and react at 70°C for 6h. After the reaction, the reaction product was washed with deionized water several times until a colorless and transparent raffinate was obtained. Finally, the product was uniformly dispersed by ultrasonic, and vacuum freeze-dried to obtain m-phenylenediamine-modified graphene oxide powder.

[0041] Preparation of composite epoxy coating: 1.36 g of m-phenylenediamine-modified graphene oxide powder was weighed, ultrasonically dispersed in 498.64 g of deionized water, and an aqueous dispersion of m-phenylenediamine-modified graphene oxide was obtained. 300g of emulsion, 500g of m-phenylenediamine-modified graphene oxide aqueous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com