Anti-tarnishing agent for cyanide-free silver plating and application thereof

A technology of cyanide-free silver plating and anti-discoloration agent, which is applied in the field of electroplating, can solve the problems of poor anti-discoloration performance of the coating, huge environmental damage, and safety hazards, and achieve the effects of improving anti-discoloration performance, solving easy discoloration, and avoiding discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The mass concentration ratio of each component of the cyanide-free silver plating anti-tarnish agent described in the present embodiment is as follows:

[0031] Sodium lauryl sulfate 0.5g / L

[0032] 2-p-aminobenzenesulfonamido-5-methoxypyrimidine 15g / L

[0033] The solvent is deionized water.

[0034] The preparation method of anti-tarnish agent for cyanide-free silver plating described in the present embodiment is as follows:

[0035] 1) Preparation of sodium lauryl sulfate solution: Dissolve 0.5 g of sodium lauryl sulfate in 200 ml of warm deionized water at about 50°C, stir to dissolve completely until clear, and set aside;

[0036] 2) Preparation of 2-p-aminobenzenesulfonyl-5-methoxypyrimidine solution: Dissolve 15 g of 2-p-aminobenzenesulfonyl-5-methoxypyrimidine in 500 ml of deionized water, slowly add 50% analytically pure hydrogen Potassium oxide solution, until the pH value is 10-13, to promote dissolution, stir to dissolve completely until clear, set aside....

Embodiment 2

[0047] The concentration ratio of each component of the silver-plated anti-tarnish agent described in the present embodiment is as follows:

[0048] Sodium Lauryl Sulfate 1g / L

[0049] 2-p-aminobenzenesulfonamido-5-methoxypyrimidine 20g / L

[0050] The solvent is deionized water.

[0051] The preparation method of the anti-tarnish agent for cyanide-free silver plating described in this embodiment is the same as that in Embodiment 1, except that the amounts of the components are calculated according to the above-mentioned proportions.

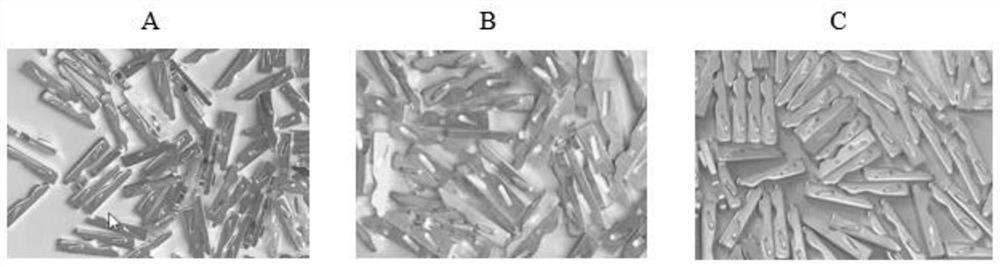

[0052] performance testing

[0053] Get 30ml of the anti-tarnish agent for cyanide-free silver plating prepared in Example 2 and add in 1L cyanide-free silver-plating solution, and the workpiece is heated at 0.5A / dm 2 , After electroplating at 40°C for 2 hours, take out the plated workpiece, treat it with a protective agent and dry it, measure the thickness of the silver-plated layer with an X-ray fluorescence meter, and place it in an atmospher...

Embodiment 3

[0059] The concentration ratio of each component of the silver-plated anti-tarnish agent described in the present embodiment is as follows:

[0060] Sodium castor oil sulfate 0.5g / L

[0061] Sodium sulfacetamide 5g / L

[0062] Sulfabenzopyrazole 5g / L

[0063] The solvent is deionized water.

[0064] The preparation method of the anti-tarnish agent for cyanide-free silver plating described in this embodiment is the same as that in Embodiment 1, except that the amounts of the components are calculated according to the above-mentioned proportions.

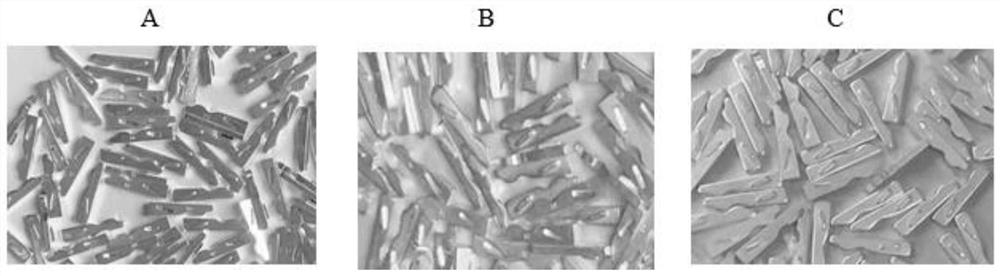

[0065] performance testing

[0066] Get 30ml of the anti-tarnish agent for cyanide-free silver plating prepared in Example 3 and add it to 1L of cyanide-free silver plating solution, and place the workpiece therein at 0.5A / dm 2 , After electroplating at 40°C for 2 hours, take out the plated workpiece, treat it with a protective agent and dry it, measure the thickness of the silver-plated layer with an X-ray fluorescence meter, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com