Anion-cation co-doped high-nickel single-crystal ternary positive electrode material as well as preparation method and application thereof

A cathode material, anion and cation technology, applied in the field of anion and cation co-doped high-nickel single crystal ternary cathode material and its preparation field, can solve the problems of poor rate performance, capacity and voltage decay, etc., to reduce sintering temperature, reduce Melting point, the effect of increasing the oxygen vacancy formation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

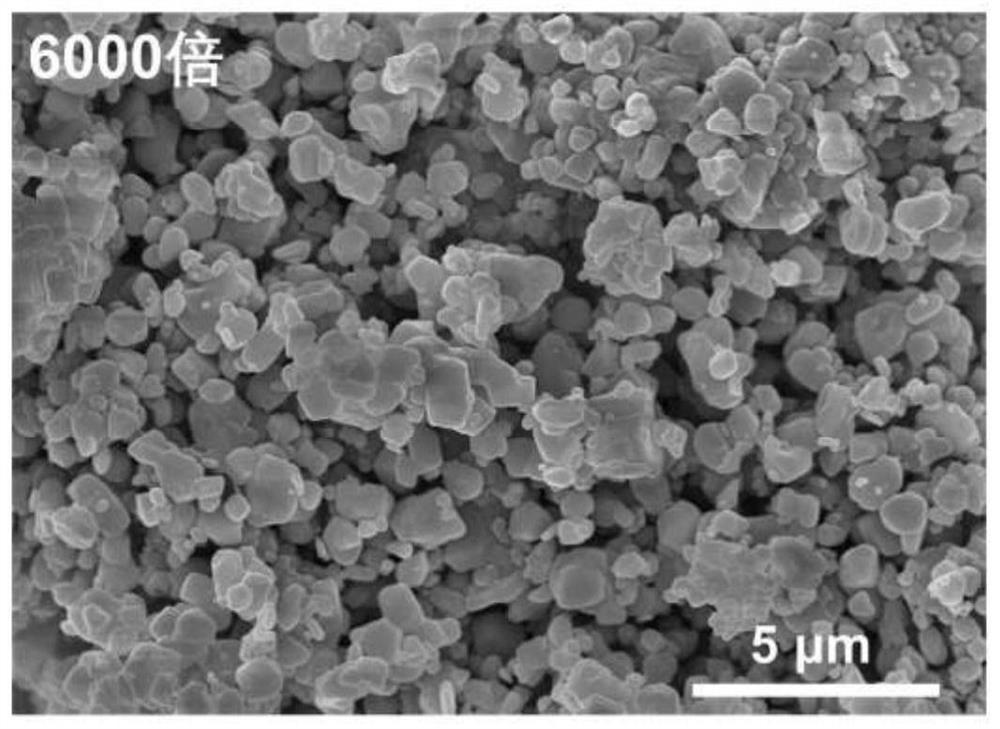

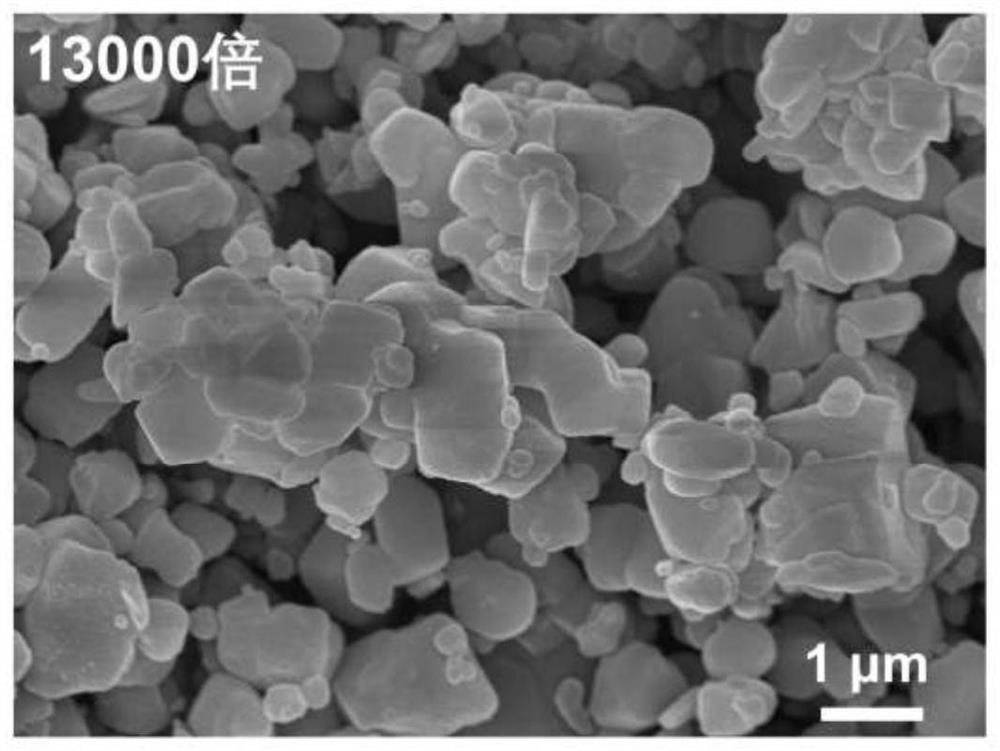

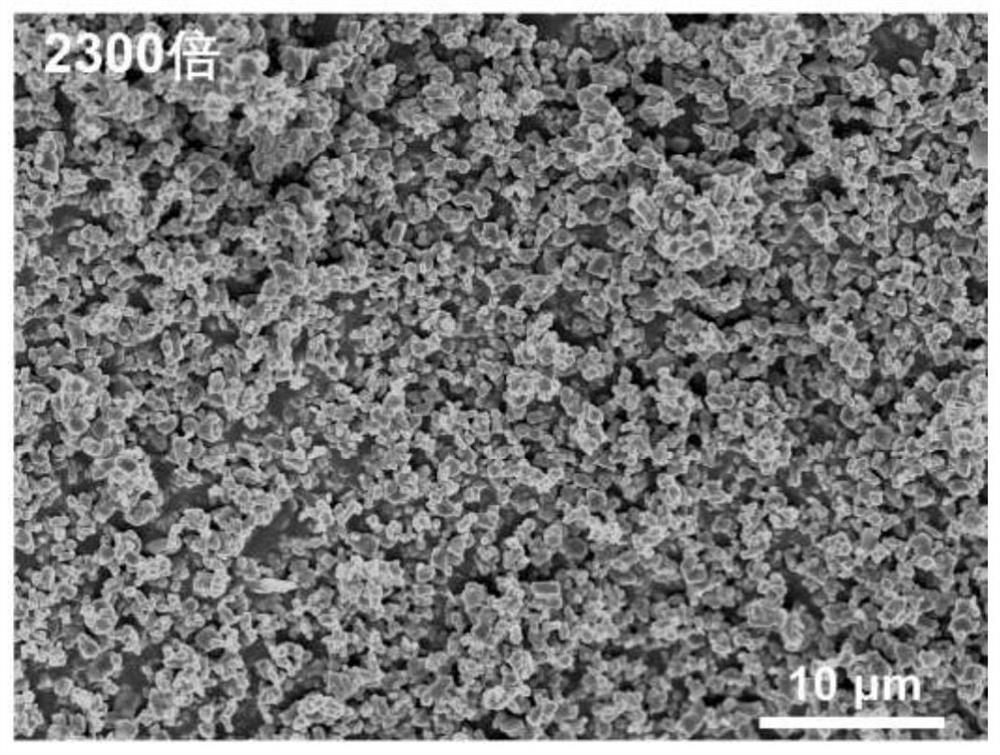

Image

Examples

Embodiment 1

[0064] The embodiment of the present invention provides a method for preparing a high-nickel single crystal ternary positive electrode material, which specifically includes the following steps:

[0065] S1, add 0.02mol Mn 0.83 Ni 0.11 co 0.06 (HO) 2 , 0.0702mol LiOH·H 2 O, 0.0966mol LiNO 3 and 0.0132mol LiCl are placed in an agate ball mill jar, and mixed for 2h in a dry environment to obtain a raw material mixture;

[0066] S2. Transfer the raw material mixture in S1 to the corundum ark, and then place it in an oxygen atmosphere, first raise the temperature to 500°C at a rate of 3°C / min, keep it warm for 5 hours, and then raise the temperature to 800°C at a rate of 3°C / min And keep it warm for 12 hours, then cool to normal temperature at a rate of 3°C / min to obtain a solid molten material;

[0067] S3. Grind the solid molten material in S2 into powder, stir with deionized water for 30 minutes, then filter and wash with deionized water and absolute ethanol for 3 times, a...

Embodiment 2

[0070] The embodiment of the present invention provides a method for preparing a high-nickel single crystal ternary positive electrode material co-doped with anions and cations, which specifically includes the following steps:

[0071] S1, add 0.02mol Mn 0.83 Ni 0.11 co 0.06 (HO) 2 , 0.000025mol Nb 2 o 5 , 0.0702mol LiOH·H 2 O, 0.0966mol LiNO 3 and 0.0132mol LiCl are placed in an agate ball mill jar, mixed in a dry environment for 2h, to obtain a raw material mixture containing Nb ion dopant;

[0072] S2. Transfer the raw material mixture containing Nb ion dopant in S1 to a corundum ark, and then place it under an oxygen atmosphere, first raise the temperature to 500°C at a rate of 3°C / min and keep it warm for 5h, then heat it up at a rate of 3°C / min. The temperature was raised to 800°C at a speed of 1 min and kept at a temperature of 12 hours, and then cooled to room temperature at a speed of 3°C / min to obtain a solid molten material;

[0073] S3, grind the solid molt...

Embodiment 3

[0078] The embodiment of the present invention provides a method for preparing a high-nickel single crystal ternary positive electrode material co-doped with anions and cations, which specifically includes the following steps:

[0079] S1, add 0.02mol Mn 0.83 Ni 0.11 co 0.06 (HO) 2 , 0.00005mol ZrO 2 , 0.0702mol LiOH·H 2 O, 0.0966mol LiNO 3 and 0.0132mol LiCl are placed in an agate ball mill jar, mixed in a dry environment for 2h, to obtain a raw material mixture containing Zr ion dopant;

[0080] S2. Transfer the raw material mixture containing Zr ion dopant in S1 to the corundum ark, and then place it under an oxygen atmosphere, first raise the temperature to 500°C at a rate of 3°C / min and keep it warm for 5h, then heat it up at a rate of 3°C / min. The temperature was raised to 800°C at a speed of 1 min and kept at a temperature of 12 hours, and then cooled to room temperature at a speed of 3°C / min to obtain a solid molten material;

[0081]S3. Grinding the solid molte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First cycle discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com