High-voltage sodium ion battery layered oxide positive electrode material

A technology for sodium ion batteries and positive electrode materials, which is applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve problems such as poor cycle performance and low energy density of positive electrode materials, achieve slow desorption, facilitate rapid transmission, and reduce The effect of layer spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of O3-NaLi 0.1 Fe 0.4 mn 0.5 o 1.9 f 0.1 Layered positive electrode material: Take 2.1mmol sodium carbonate, 0.2mmol lithium fluoride, 1.6mol ferrous oxide, and 2mol manganese oxide and mix them in a ball mill jar, fill the ball mill jar with Ar gas protection gas, and the ratio of the ball to material is 40: 1. The speed of the ball mill is 600rpm, the running time is 120min, and the four materials are fully mixed;

[0040] (2) Place the above mixed material in a muffle furnace for calcination, the heating rate is 5°C min -1 , the temperature is 900°C, the holding time is 16h, and cooled to room temperature; the calcined material is ground into powder.

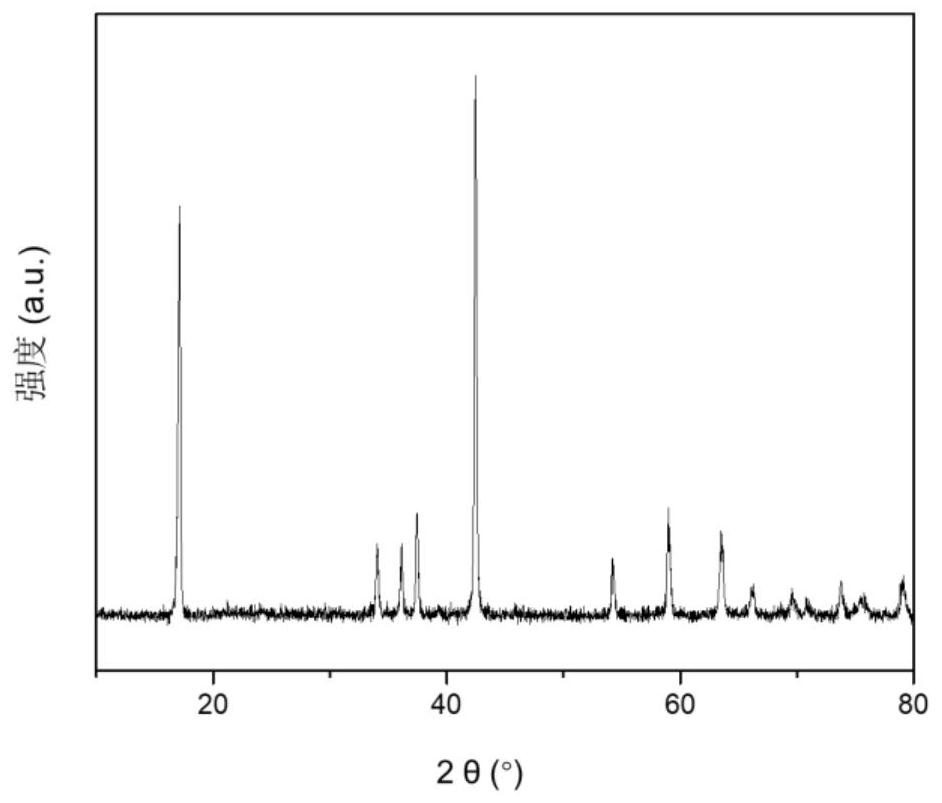

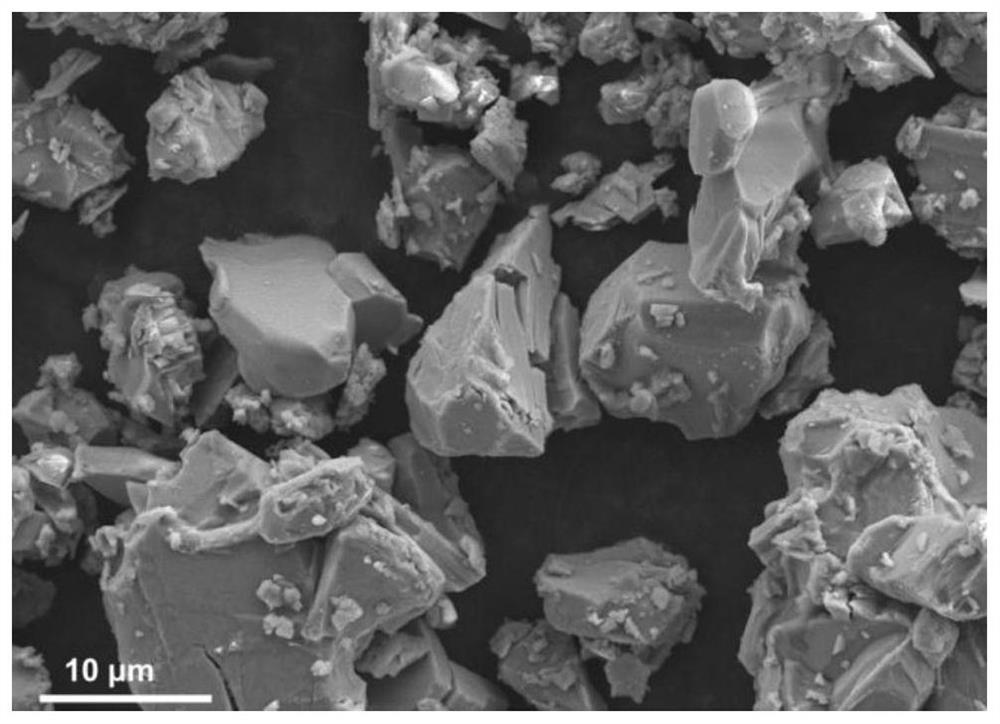

[0041] Carry out XRD test on the prepared powder material, such as figure 1 As shown, it can be found that the material is a pure O3 phase, the space group is R-3m(166), and the microscopic morphology of the material is micron-sized particles, such as figure 2shown. The prepared positive electr...

Embodiment 2

[0048] (1) Preparation of P2-Na 0.8 Li 0.12 Ni 0.22 mn 0.66 o 1.92 f 0.08 Layered positive electrode material: Take 0.42mmol sodium carbonate, 0.08mmol lithium fluoride, 0.08mmol lithium carbonate, 0.22mol nickel oxide, 0.66mol manganese oxide and mix them in a ball mill tank. The ball material ratio is 60:1, and the ball mill speed is 450rpm, running time is 60min, fully mix several materials;

[0049] (2) Place the above mixed material in a muffle furnace for calcination, the heating rate is 5°C min -1 , the temperature is 950°C, the holding time is 12h, and the cooling rate is 1°C min -1 ; Grinding the calcined material into powder.

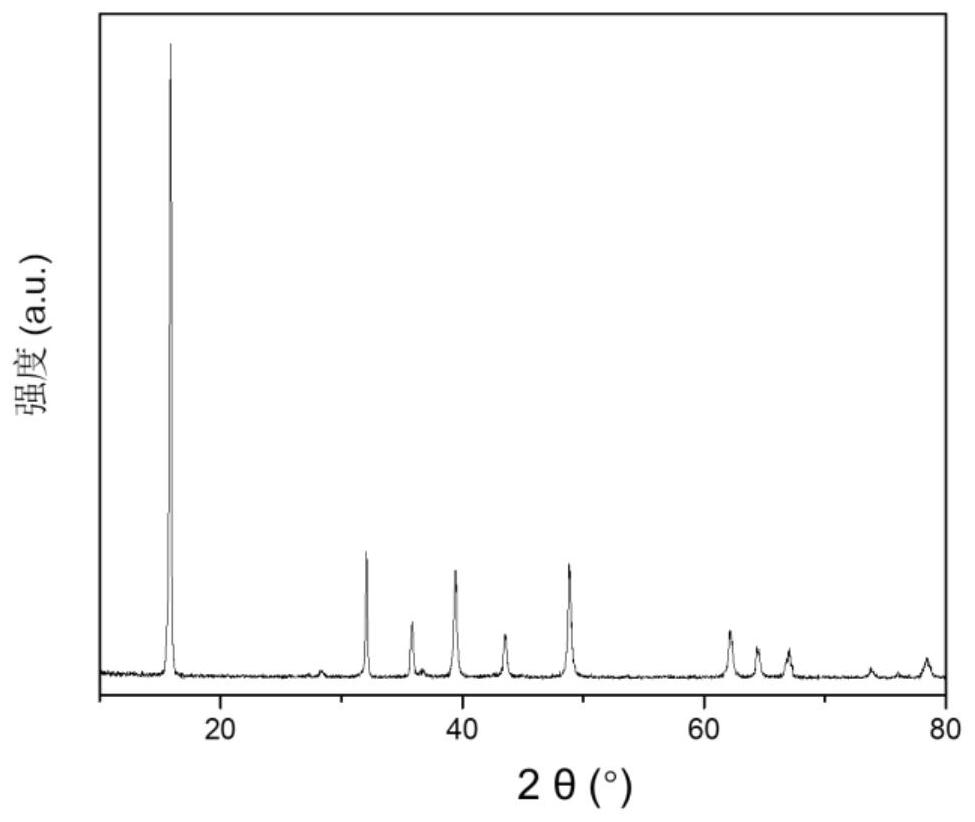

[0050] Carry out XRD test on the prepared powder material, such as image 3 As shown, it can be found that the material behaves as a pure P2 phase with a space group of P 63 / mmc, through the transmission electron microscope test, it can be seen that the material is a layered single crystal structure, such as Figure 4 shown. SEM te...

Embodiment 3

[0057] (1) Preparation of P2-Na 0.8 Li 0.3 Ni 0.2 mn 0.5 o 1.7 f 0.3 Layered positive electrode material: Mix 0.42mmol sodium carbonate, 0.3mmol lithium fluoride, 0.2mol nickel oxide, and 0.5mol manganese oxide and put them in a ball mill tank, fill the ball mill tank with Ar gas protection gas, and the ratio of ball material is 50: 1. The speed of the ball mill is 450rpm, the running time is 60min, and several materials are fully mixed;

[0058] (2) Place the above mixed material in a muffle furnace for calcination, the heating rate is 5°C min -1 , the temperature is 950°C, the holding time is 12h, and the cooling rate is 1°C min -1 ; Grinding the calcined material into powder.

[0059] The material behaves as a pure P2 phase with space group P 63 / mmc, the microscopic morphology of the material is micron-sized particles. According to the scheme in Example 1, a sodium-ion battery pole piece was prepared and a sodium-ion half-cell was assembled. Carry out the constan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com