Preparation method of guar gum enzymatic hydrolysate with high GM ratio

A technology for guar gum and enzymatic hydrolysis products is applied in the field of preparation of guar gum enzymatic hydrolysis products to achieve the effects of promoting intestinal development, improving intestinal antioxidant and immune capabilities, and improving growth performance and disease resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

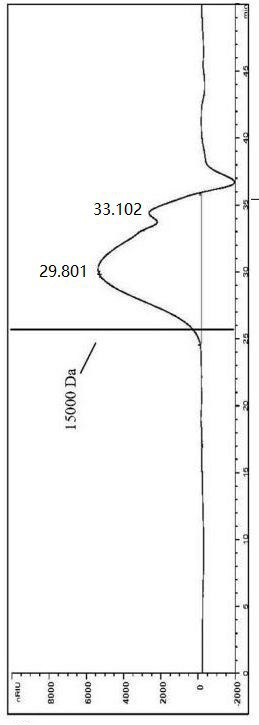

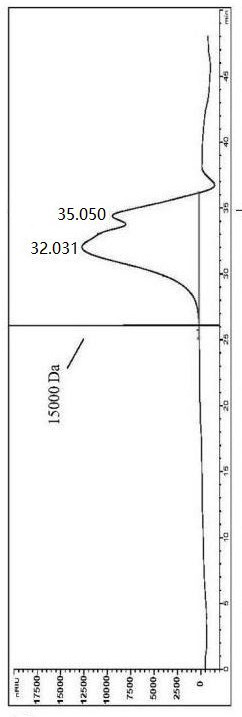

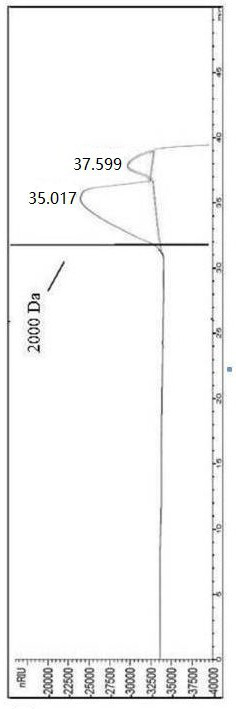

[0039] Example 1: The present invention provides a high Gm ratio of Guar bean adhesively preparation method, such as Figure 9 As shown, the specific steps are as follows:

[0040] 1 kg Guoli adhesive in the autoclave of 135 ° C pressure degradation 2 h, in accordance with the mass ratio of solid fluid than 1:15, the high-pressure degradation of Guar bean gum is filled with hydrochloric acid, and the pH is 4.0 to each gram. The pressurized degradation substrate was added to the beta-mannan 1000 u, and the plant hydrolase 700 U was enzymatically hydrolyzed, and the temperature of the temperature of 55 ° C was reacted 6 h, after the reaction, the enzymatic hydrolyzide was cooled, horizontal The spiral centrifuge is separated from the supernatant, concentrated by vacuum reduction (the vacuum is -0.08 MPa, temperature 60 ° C, time 2 h), spray dry, and produce high Gm ratio of Guar beans enzymatic hydrolysis product.

[0041] The molecular weight distribution of the high Gm ratio of the...

Embodiment A

[0050] Preferred Example A, a special mating feed for promoting sequivial sequenisencinity and intestinal health development, including the following weight materials:

[0051] raw material Proportion Fish powder 8% Wheat flour 10% Glutinum 4% Enzymatic algae powder 36% Sea motor 38.5% Phospholipid 1% Polyvilty 1% Multi-ore 1% High GM ratio of Guar bean adhesive 0.1% Composite lysozyme 0.4%

[0052] Each raw material in the formulation is mixed in a scale in the table, 60 S is mixed in a mixer at a rotational speed of 200 R / min, and stirred at a mass ratio of 15 min according to the mass ratio of the raw material 2: 1, and a reunion wet material is prepared.

Embodiment B

[0053] Example B, a special mating feed for promoting sequivial sexy and intestinal health development, including the following weight materials:

[0054] raw material Proportion Fish powder 8% Wheat flour 10% Glutinum 4% Enzymatic algae powder 36% Sea motor 38% Phospholipid 1% Polyvilty 1% Multi-ore 1% High GM ratio of Guar bean adhesive 0.2% Composite lysozyme 0.8%

[0055] Each raw material in the formulation is mixed in a scale in the table, 60 S is mixed in a mixer at a rotational speed of 200 R / min, and stirred at a mass ratio of 15 min according to the mass ratio of the raw material 2: 1, and a reunion wet material is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com