Preparation method of plywood for bakelite box

A technology for plywood and bakelite boxes, which is applied in the field of preparation of plywood for bakelite boxes, and can solve problems such as decline, moldy service life, and low adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing plywood for bakelite boxes, which is obtained by gluing three veneer boards together with an adhesive;

[0038] The adhesive includes the following raw materials in parts by weight: 20 parts of modified resin, 3 parts of modified graphene, 3 parts of benzyldimethylamine, 1 part of sulfated castor oil, 1 part of sodium dodecylsulfonate, 1 part of o-phenylphenol parts, 10 parts of water;

[0039] The adhesive is made by the following steps:

[0040] Step S1: Add modified resin, sulfated castor oil, sodium dodecylsulfonate, and water into a stirring tank, and stir for 1 hour at a rotation speed of 1000 r / min to obtain a mixture;

[0041] Step S2: After the mixture and the modified graphene were ultrasonically treated at a frequency of 8 kHz for 30 min, benzyldimethylamine was added and stirred for 3 h at a rotational speed of 1500 r / min to prepare an adhesive.

[0042] Modified resin is made by the following steps:

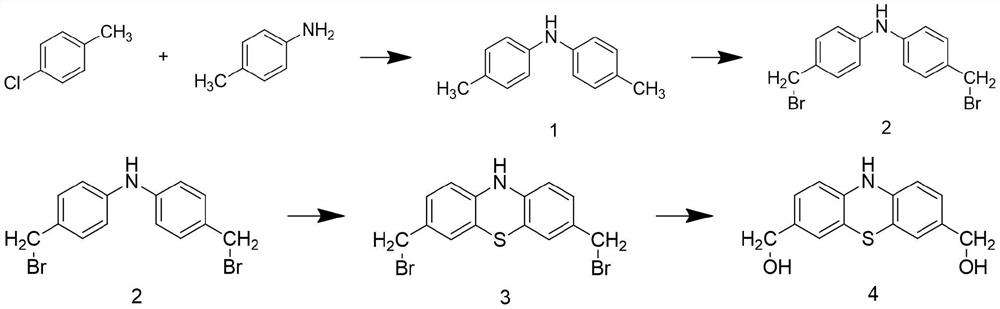

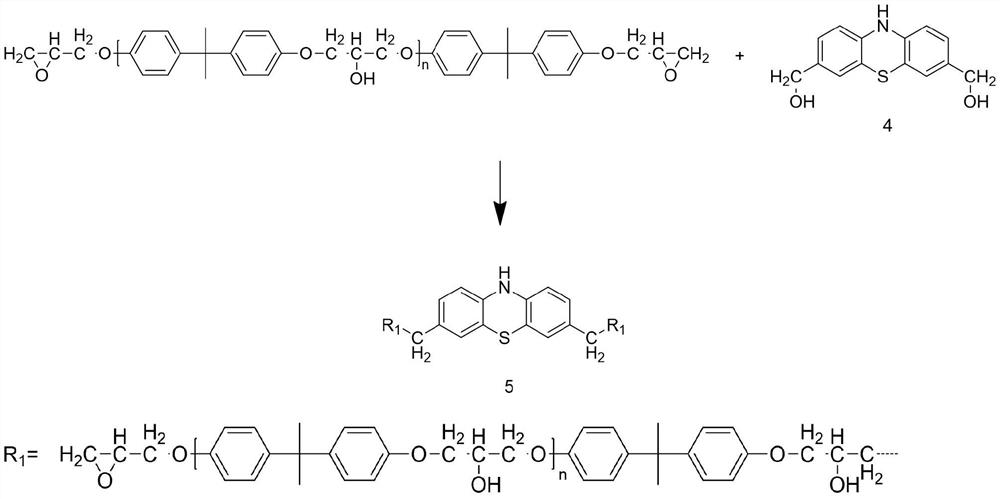

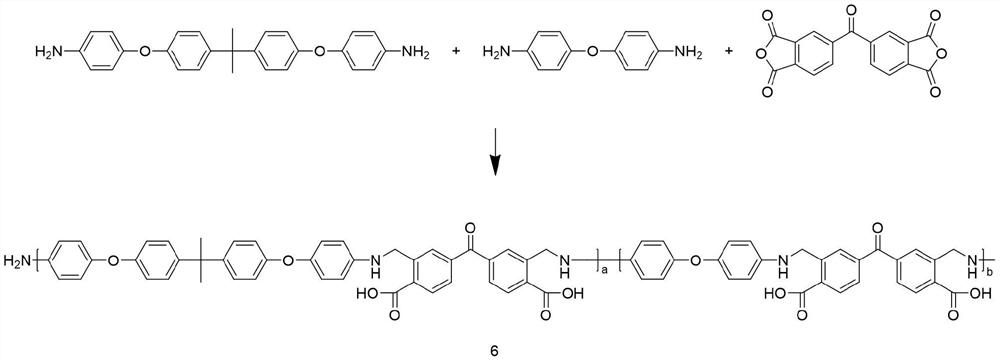

[0043] Step A1: Add p-chloroto...

Embodiment 2

[0050] A method for preparing plywood for bakelite boxes, which is obtained by gluing three veneer boards together with an adhesive;

[0051] The adhesive includes the following raw materials in parts by weight: 25 parts of modified resin, 4 parts of modified graphene, 4 parts of benzyldimethylamine, 2 parts of sulfated castor oil, 2 parts of sodium dodecylsulfonate, 2 parts of o-phenylphenol parts, 13 parts of water;

[0052] The adhesive is made by the following steps:

[0053] Step S1: Add modified resin, sulfated castor oil, sodium dodecylsulfonate, and water into a stirring tank, and stir for 1.3 hours at a rotation speed of 1200 r / min to obtain a mixture;

[0054] Step S2: ultrasonically treat the mixture and the modified graphene at a frequency of 9 kHz for 35 min, then add benzyldimethylamine, and stir for 4 h at a rotational speed of 1800 r / min to prepare an adhesive.

[0055] Modified resin is made by the following steps:

[0056] Step A1: Add p-chlorotoluene, p-m...

Embodiment 3

[0063] A method for preparing plywood for bakelite boxes, which is obtained by gluing three veneer boards together with an adhesive;

[0064] The adhesive includes the following raw materials in parts by weight: 30 parts of modified resin, 5 parts of modified graphene, 5 parts of benzyldimethylamine, 3 parts of sulfated castor oil, 3 parts of sodium dodecylsulfonate, 3 parts of o-phenylphenol parts, 15 parts of water;

[0065] The adhesive is made by the following steps:

[0066] Step S1: Add modified resin, sulfated castor oil, sodium dodecylsulfonate, and water into a stirring tank, and stir for 1.5 hours at a rotation speed of 1200 r / min to obtain a mixture;

[0067] Step S2: ultrasonically treat the mixture and the modified graphene at a frequency of 10 kHz for 40 min, then add benzyldimethylamine, and stir for 5 h at a rotational speed of 2000 r / min to prepare an adhesive.

[0068] Modified resin is made by the following steps:

[0069] Step A1: Add p-chlorotoluene, p-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com