Nano composite material integrating heat conduction and wave absorption and preparation method thereof

A technology of nano-composite materials and wave-absorbing fillers is applied in the field of nano-composite materials and their preparation, and achieves the effects of great scientific significance, great practical application value, and simple process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

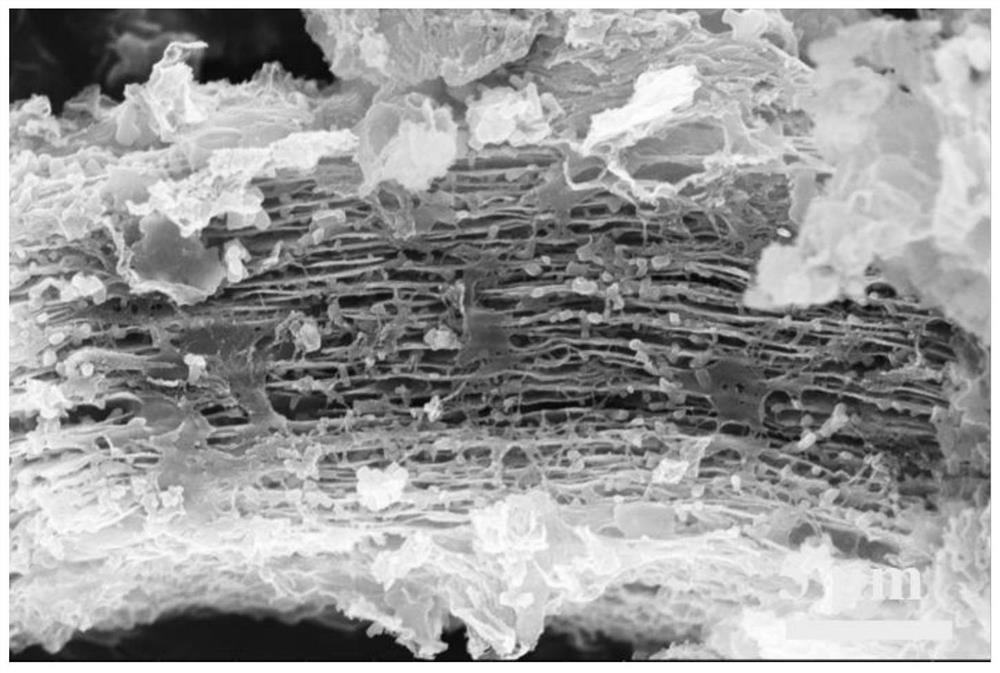

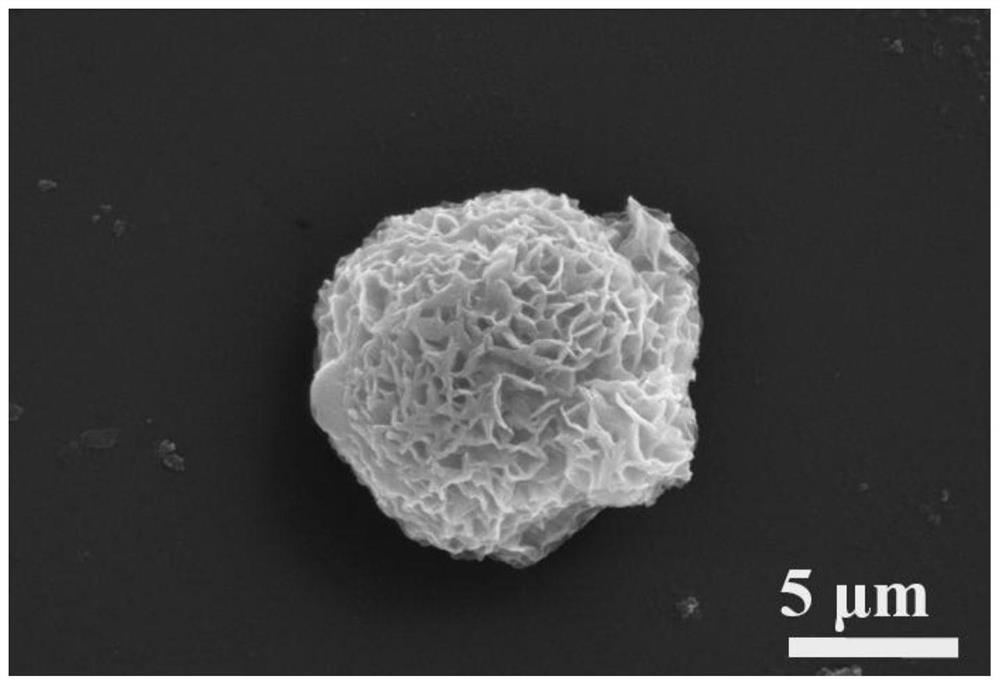

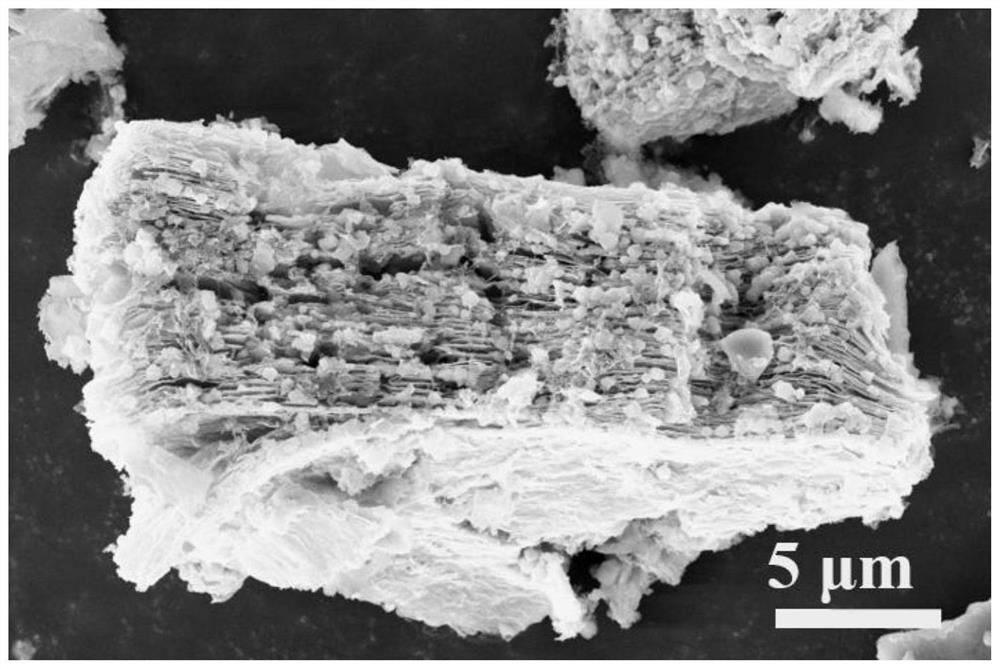

Image

Examples

Embodiment 1

[0020] A method for preparing a nanocomposite material integrating heat conduction and wave absorption, specifically comprising the following steps:

[0021] Step 1: Weigh 1.0 g of titanium carbide obtained by hydrofluoric acid etching, add 150 mL of deionized water, and ultrasonically disperse for 1 to 2 hours at 60 ° C, and the mixed solution is set aside;

[0022] Step 2: Take 1.0 g of boric acid and 6.0 g of urea and add them all to the above mixed solution, and stir and dry the mixed solution at 80° C. until the mixed solution is completely dried to obtain dry solid powder;

[0023] Step 3: Transfer the dry solid powder obtained above to a porcelain boat and place it in a closed tube furnace, vacuumize and replace with argon three times, then start the reaction at a heating rate of 5°C / min, and control the pressure of the closed tube furnace system 0.2MPa, until the system temperature reaches 900°C, keep it for 3 hours, then continue to increase the temperature at 1°C / min...

Embodiment 2

[0025] A method for preparing a nanocomposite material integrating heat conduction and wave absorption, specifically comprising the following steps:

[0026] Step 1: Weigh 0.8g of molybdenum disulfide nanosheets prepared by the conventional hydrothermal method, add 150mL of deionized water, and disperse ultrasonically for 1 to 2 hours at 60°C, and prepare the mixed solution for later use;

[0027] Step 2: Take 1.0 g of boric acid and 5.0 g of urea and add them all to the above mixed solution, and stir and dry the mixed solution at 80° C. until the mixed solution is completely dried to obtain dry solid powder;

[0028] Step 3: Transfer the dry solid powder obtained above to a porcelain boat and place it in a closed tube furnace, vacuumize and replace with argon three times, then start the reaction at a heating rate of 10°C / min, and control the pressure of the closed tube furnace system 0.2MPa, until the system temperature reaches 900°C, keep it for 3 hours, then continue to inc...

Embodiment 3

[0030] A method for preparing a nanocomposite material integrating heat conduction and wave absorption, specifically comprising the following steps:

[0031] Step 1: Weigh 1.0 g of titanium carbide obtained by hydrofluoric acid etching and add it to 200 mL of deionized water. At 60 ° C, ultrasonically disperse for 1 to 2 hours, and the mixed solution is set aside;

[0032] Step 2: Take 1.5g of boric acid and 10.0g of urea and add them all to the above mixed solution, and stir and dry the mixed solution at 80°C until the mixed solution is completely dried to obtain dry solid powder;

[0033] Step 3: Transfer the dry solid powder obtained above to a porcelain boat and place it in a closed tube furnace, vacuumize and replace with argon three times, then start the reaction at a heating rate of 10°C / min, and control the pressure of the closed tube furnace system 0.5MPa until the system temperature reaches 900°C, keep it for 3 hours, then continue to increase the temperature at 5°C / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com