Additive for reducing contamination problem in biomass combustion process and use method

A combustion process and biomass technology, applied in the directions of fuel additives, biofuels, waste fuels, etc., can solve the problems of strong adhesion of biomass combustion fouling ash, reduced heat transfer coefficient of heating surface, and blocked flue, etc. Strong flexibility and adaptability to fuel types, strong high-temperature adsorption capacity, and low cost of transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

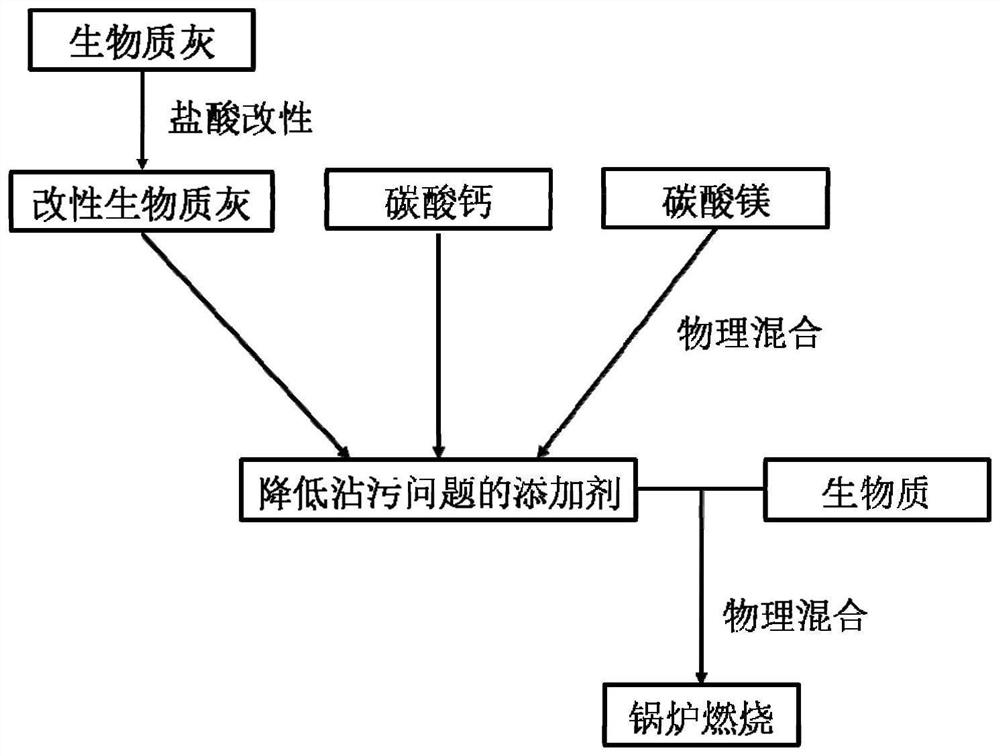

Method used

Image

Examples

Embodiment 1

[0046] Disperse biomass ash from a domestic biomass power plant in a ratio of 10g:300ml in a hydrochloric acid solution with a concentration of 4mol / L to obtain a solid-liquid mixture;

[0047] Stir the solid-liquid mixture at a temperature of 70°C for 6 hours;

[0048] The stirred solid-liquid mixture is placed in a filter device to filter, and the biomass ash on the filter screen is rinsed with deionized water until the Cl of the solution in the filter device - If the concentration is less than 0.01mol / L, dry the biomass ash on the filter in an oven at 35°C, grind and sieve to 50-75μm to obtain modified biomass ash;

[0049] Grinding and sieving calcium carbonate and magnesium carbonate to 75-100 μm respectively;

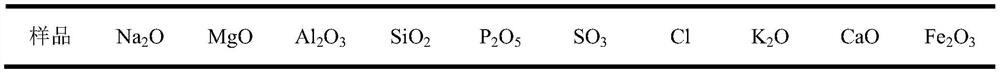

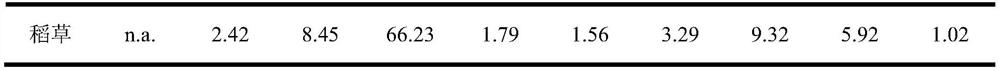

[0050] According to the composition analysis of straw ash in Table 1, the modified biomass ash, calcium carbonate and magnesium carbonate were put into the stirring device according to the mass ratio of 0.3:0.35:0.35. Additives to reduce pollution from biomass b...

Embodiment 2

[0056] Disperse biomass ash from a domestic biomass power plant in a ratio of 30g:300ml in a hydrochloric acid solution with a concentration of 8mol / L to obtain a solid-liquid mixture;

[0057] Stir the solid-liquid mixture at a temperature of 100°C for 8 hours;

[0058] The stirred solid-liquid mixture is placed in a filter device to filter, and the biomass ash on the filter screen is rinsed with deionized water until the Cl of the solution in the filter device - If the concentration is less than 0.01mol / L, dry the biomass ash on the filter in an oven at 45°C, grind and sieve to 50-75μm to obtain modified biomass ash;

[0059] Grinding and sieving calcium carbonate and magnesium carbonate to 75-100 μm respectively;

[0060] According to the composition analysis of camphor wood ash in Table 2, the modified biomass ash, calcium carbonate and magnesium carbonate were put into the stirring device according to the ratio of mass ratio 0.8:0.1:0.1, the rotating speed of the stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com