High-purity argon purification process and device

A high-purity, argon technology, applied in the direction of inert gas compounds, specific gas purification/separation, inorganic chemistry, etc., can solve the problem of working temperature, high-purity argon purification equipment and suction that cannot be at the best adsorption activity at the same time Increased procurement costs of reagent materials, unstable purity of high-purity argon gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

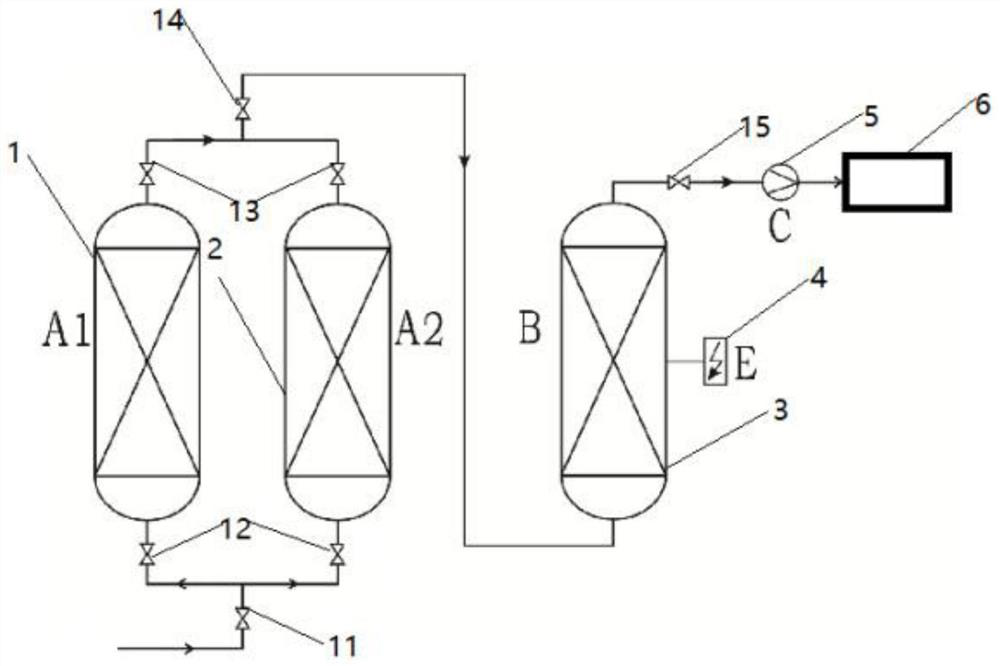

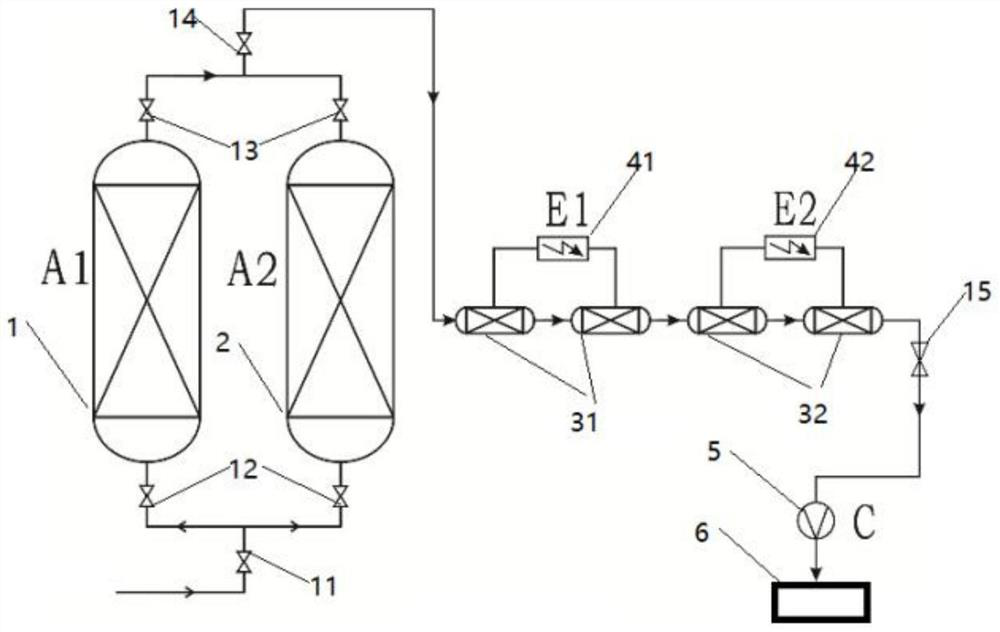

[0026] Attached below figure 2 The implementation of the technical solution of the present invention is described in further detail:

[0027] Now take the process flow of the purification equipment of the high-purity argon purification plant of Masteel Gas Company as an example:

[0028] Masteel's high-purity argon gas purification plant purification equipment process flow and equipment include: 2 adsorption towers arranged in parallel, namely A1 adsorption tower 1 and A2 adsorption tower 2, one for operation and one for regeneration. The raw material gas first passes through the raw material argon inlet valve 11, then enters the A1 adsorption tower 1 through the A1 adsorption tower inlet valve 12 or enters the A2 adsorption tower 2 through the A2 adsorption tower inlet valve 13, and absorbs water and carbon dioxide in the raw material pure argon gas , acetylene, the inlet valves of the two adsorption towers are automatically switched on and off according to the process design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com