Tantalum-containing refractory material for blast furnace ceramic cup and preparation method of tantalum-containing refractory material

A technology for refractory materials and ceramic cups, applied in the field of refractory materials, can solve the problems of poor refractory performance and insufficient strength of refractory materials, and achieve the effects of improving fracture toughness, prolonging service life and excellent compressive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

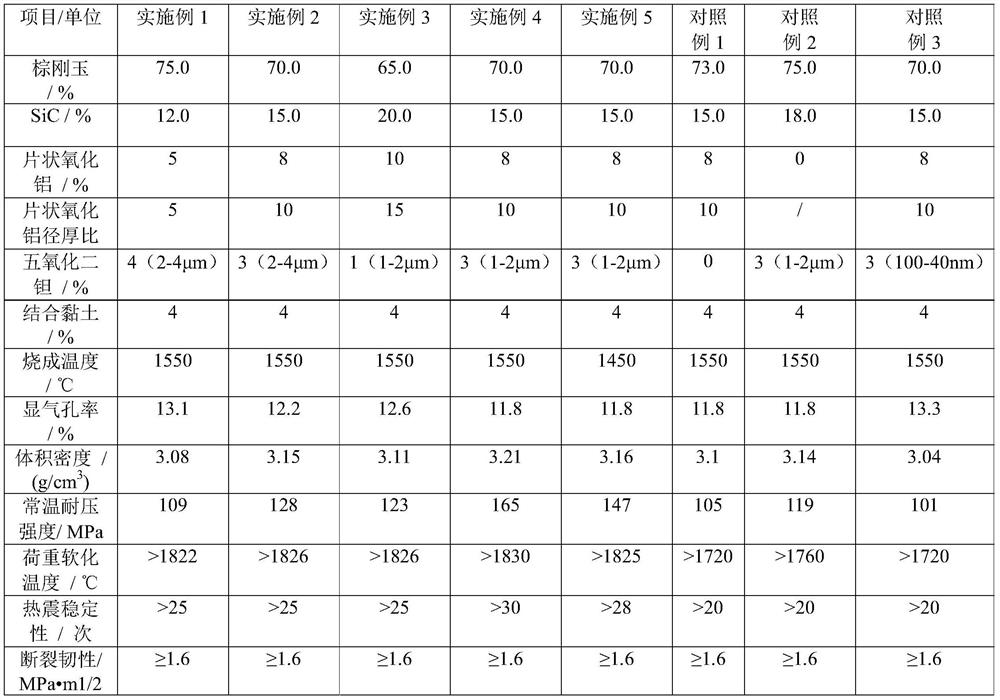

Embodiment 1

[0023] The new ceramic cup refractory material of the present invention is represented by weight percentage, and its raw material composition is: brown corundum 75%, silicon carbide 12%, flaky alumina powder 5%, bonded clay 4%, tantalum pentoxide 4% ; Add the above-mentioned 3% of the total weight of the binder. The particle size of tantalum pentoxide is 2.0 μm-4.0 μm. The particle size of flake alumina is 1.0-2.0 μm, and the aspect ratio is 5.0; the binder is composed of sulfonate and lignin, and the mass ratio of sulfonate and lignin is 1:1.

[0024] The preparation steps are:

[0025] (1) Mixing: After co-grinding brown corundum and silicon carbide evenly, add a binder and mix for 6 minutes; then add flake alumina, tantalum pentoxide and bonded clay and mix for 15 minutes to obtain a well-mixed wet material.

[0026] (2), molding: the molding wet material of step (1) gained is pressed into brick adobe under 200 pressure;

Embodiment 2

[0030] The new ceramic cup refractory material of the present invention is represented by weight percentage, and its raw material composition is: brown corundum 70%, silicon carbide 15%, flaky alumina powder 8%, bonded clay 4%, tantalum pentoxide 3% ; Add the above-mentioned 3% of the total weight of the binder. The particle size of tantalum pentoxide is 2.0 μm-4.0 μm. The particle size of flake alumina is 2.0-3.0μm, and the aspect ratio is 5.0; the binder is composed of sulfonate and lignin, and the ratio of sulfonate and lignin is 1:1.

[0031] The preparation steps are:

[0032] (1) Mixing: After co-grinding brown corundum and silicon carbide evenly, add a binder and mix for 6 minutes; then add flake alumina, tantalum pentoxide and bonded clay and mix for 15 minutes to obtain a well-mixed wet material.

[0033] (2), molding: the molding wet material of step (1) gained is pressed into brick adobe under 200 pressure;

[0034] (3), drying: dry the adobe obtained in step (2...

Embodiment 3

[0037] The new ceramic cup refractory material of the present invention is represented by weight percentage, and its raw material composition is: brown corundum 65%, silicon carbide 20%, flaky alumina powder 10%, bonded clay 4%, tantalum pentoxide 1% ; Add the above-mentioned 3% of the total weight of the binder. The particle size of tantalum pentoxide is 1.0 μm-2.0 μm. The particle size of flake alumina is 3.0-5.0 μm, and the aspect ratio is 15; the binder is composed of sulfonate and lignin, and the ratio of sulfonate and lignin is 1:1.

[0038] The preparation steps are:

[0039] (1) Mixing: After co-grinding brown corundum and silicon carbide evenly, add a binder and mix for 6 minutes; then add flake alumina, tantalum pentoxide and bonded clay and mix for 15 minutes to obtain a well-mixed wet material.

[0040] (2), molding: the molding wet material of step (1) gained is pressed into brick adobe under 200 pressure;

[0041] (3), drying: dry the adobe obtained in step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com