Refining method of gadadotec acid meglumine

A technology of gadoteric acid meglumine and meglumine is applied in the field of preparation and purification of gadoteric acid meglumine, and can solve problems such as affecting the nervous system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

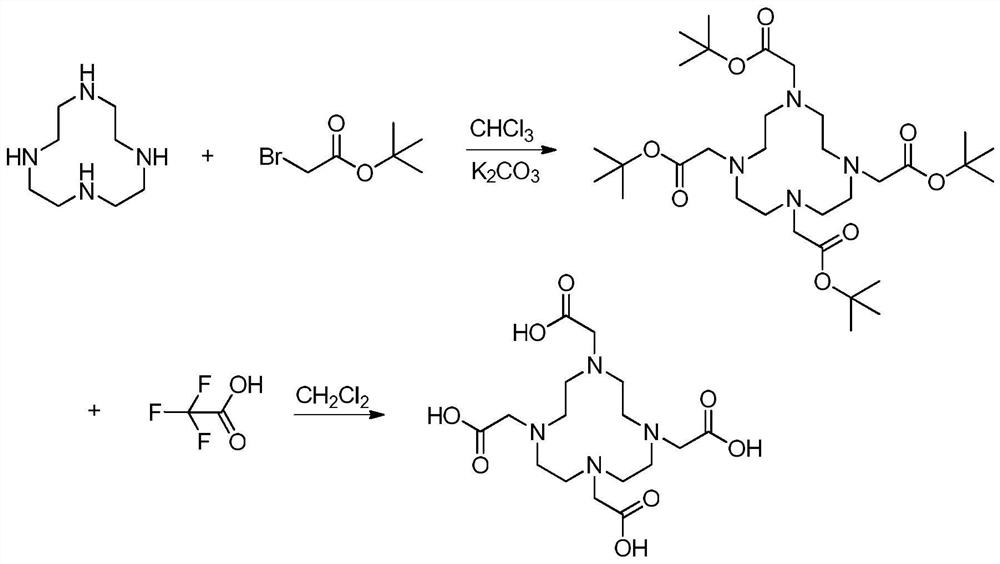

Method used

Image

Examples

Embodiment 2

[0030] Add 3.75g of purified DOTA to the reaction bottle, add pure water, stir and dissolve at room temperature, add gadolinium oxide (2.15g) and microporous calcium silicate particles 15g, then add 2.2-3g of meglumine until the solution pH=7 -9, ultrasonically oscillate for 1 hour, filter, heat the filtrate to 40-50°C and stir at a speed of 80r / min, react for 2-4 hours, filter the precipitate, and dry it in vacuum.

[0031] The microporous calcium silicate particles have an average pore diameter of 20-50nm, ultrasonic frequency of 20-50KHZ, and power of 150W.

[0032] The purity of the gadoterate meglumine prepared by the invention is more than or equal to 99.6%, the content of simple impurities is less than 0.02%, and the content of free gadolinium is less than 0.001%.

Embodiment 3

[0034] Add 3.75g of purified DOTA to the reaction bottle, add pure water, stir and dissolve at room temperature, add gadolinium oxide (2.15g) and microporous calcium silicate particles 15g, then add 2.2-3g of meglumine until the solution PH=8 -9, ultrasonically oscillate for 1 hour, filter, heat the filtrate to 40-50°C and stir at a speed of 80r / min, react for 2-4 hours, filter the precipitate, and dry it in vacuum.

[0035] The microporous calcium silicate particles have an average pore diameter of 20-50nm, ultrasonic frequency of 20-50KHZ, and power of 150W.

[0036] The purity of the gadoterate meglumine prepared by the invention is more than or equal to 99.6%, the content of simple impurities is less than 0.02%, and the content of free gadolinium is less than 0.001%.

[0037] Dissolve 2 g of the above-mentioned gadoterate meglumine in 100 ml of methanol, heat to dissolve under stirring, add 50 ml of water under stirring, stop stirring, cool down naturally, slowly precipita...

Embodiment 4

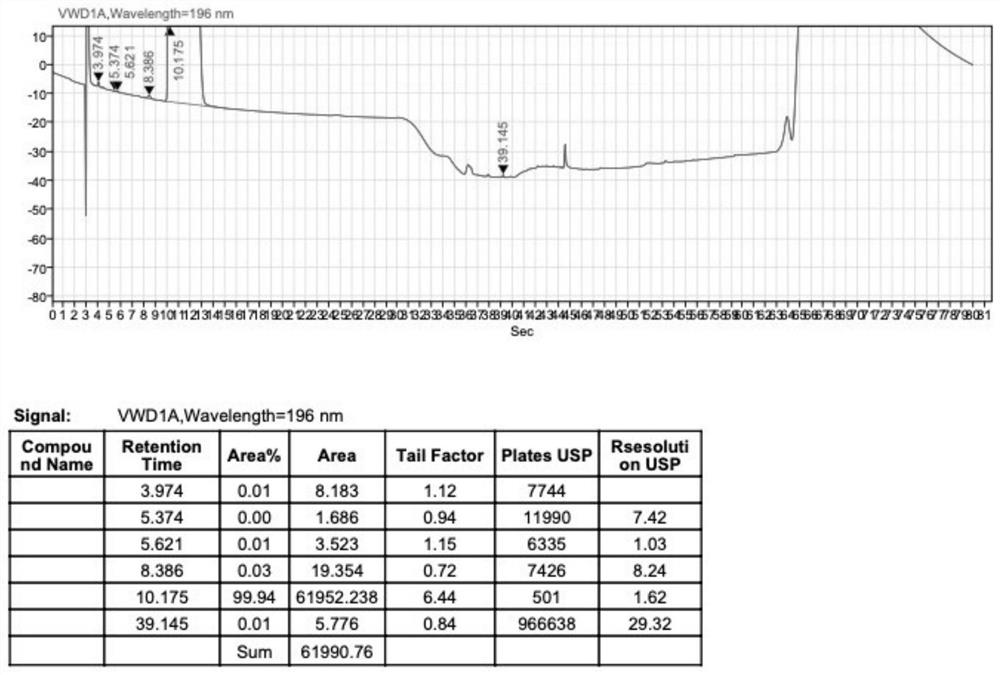

[0039] The gadoteric acid meglumine 2g that comparative example 1 obtains is dissolved in the methanol of 100ml, is heated to dissolving under stirring, adds 50ml water under stirring, stops stirring, naturally cools down, slowly separates out fine crystal, cools to 5 after 3 hours. Add 30ml of water under stirring at -10°C, stop stirring after adding, place to crystallize, filter the precipitated white crystals with suction, wash with a small amount of methanol, and dry in vacuum at 60°C to obtain a crystalline powder with a purity of 99.6% by HPLC analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com