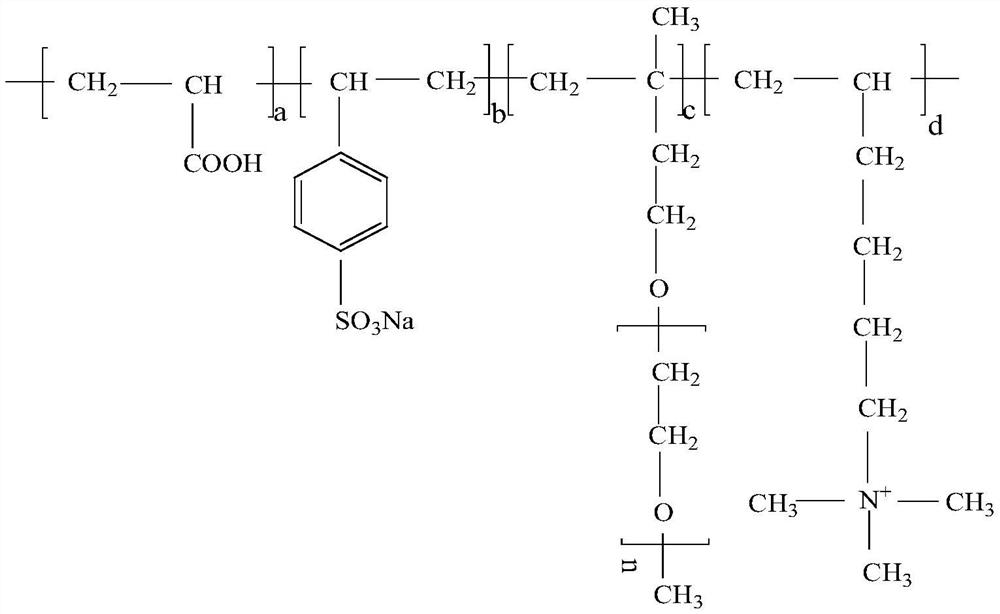

Amphoteric polycarboxylate dispersing agent with macromolecular large branched chain and preparation method of amphoteric polycarboxylate dispersing agent

An amphoteric polycarboxylic acid, macromolecular technology, used in fuel additives, liquid carbon-containing fuels, petroleum industry, etc., to achieve excellent viscosity reduction, simple steps, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

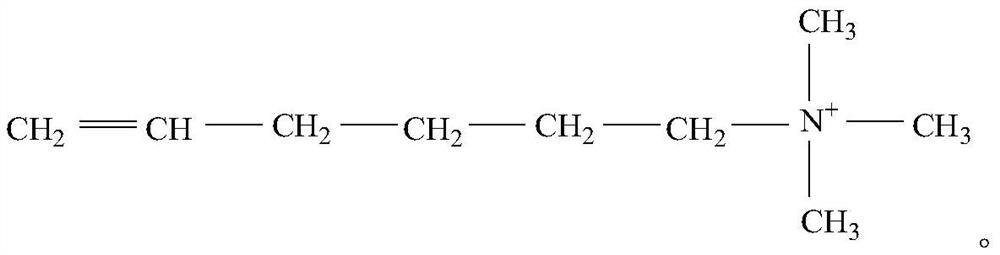

[0031] Example 1 An amphoteric polycarboxylate dispersant without macromolecular macrobranches. Using acrylic acid, sodium styrene sulfonate and trimethylenhexyl ammonium bromide as raw materials, it is synthesized by free radical polymerization, and the steps are as follows:

[0032] S1. Take a 250mL beaker, weigh 27.69g of acrylic acid, 39.81g of sodium styrene sulfonate (the molar ratio of acrylic acid: sodium styrene sulfonate is 2:1), and 70g of pure water in the beaker, add a magnet, a magnetic stirrer Stir until completely dissolved, pour into a dropper bottle for later use;

[0033] S2. Get a 50mL small beaker, weigh 2.5g of trimethylenhexyl ammonium bromide, add 10g of purified water to dissolve and set aside;

[0034] S3. take by weighing initiator 2.4g ammonium persulfate and be dissolved in 10g purified water for subsequent use;

[0035] S4. Take a 250mL four-necked flask, wash it and dry it, add 40g of isopropanol to the 250mL four-necked flask at room temperatu...

Embodiment 2

[0037] Example 2 An amphoteric polycarboxylate dispersant with macromolecular macrobranches. Using acrylic acid, methallyl alcohol polyoxyethylene ether and trimethylenhexyl ammonium bromide as raw materials, it is synthesized by free radical polymerization, and the steps are as follows:

[0038] S1. Take a 250mL beaker, weigh 14g of methallyl alcohol polyoxyethylene ether with a molecular weight of 1000, 53.5g of acrylic acid, and 70g of pure water into the beaker, add a magnet, stir with a magnetic stirrer until completely dissolved, and pour it into a drop bottle in standby;

[0039]S2. Get a 50mL small beaker, weigh 2.5g of trimethylenhexyl ammonium bromide, add 10g of purified water to dissolve and set aside;

[0040] S3. take by weighing initiator 2.4g ammonium persulfate and be dissolved in 10g purified water for subsequent use;

[0041] S4. Take a 250mL four-necked flask, wash it and dry it, add 40g of isopropanol to the 250mL four-necked flask at room temperature, u...

Embodiment 3

[0043] Example 3 A polycarboxylate dispersant with macromolecular macrobranches. Using acrylic acid, sodium styrene sulfonate, and methallyl alcohol polyoxyethylene ether as raw materials, it is synthesized by free radical polymerization, and the steps are as follows:

[0044] S1. Take a 250mL beaker, weigh 10.5g of methallyl alcohol polyoxyethylene ether with a molecular weight of 1000, 24.41g of acrylic acid, and 35.09g of sodium styrene sulfonate (the molar ratio of acrylic acid: sodium styrene sulfonate is 2:1 ), 80g of pure water in a beaker, add a magnet, and stir with a magnetic stirrer until completely dissolved, then pour it into a dropper for subsequent use;

[0045] S2. take by weighing initiator 2.4g ammonium persulfate and be dissolved in 10g purified water for subsequent use;

[0046] S3. Take a 250mL four-necked flask, wash it and dry it, add 40g of isopropanol to the 250mL four-necked flask at room temperature, use an oil bath to heat the four-necked flask to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com