Super-hydrophobic and high-stability nano ceramic coating and application method thereof

A nano-ceramic, high-stable technology, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of high price, difficult process and large-scale application, and achieve simple use process, cost reduction, and simple use method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

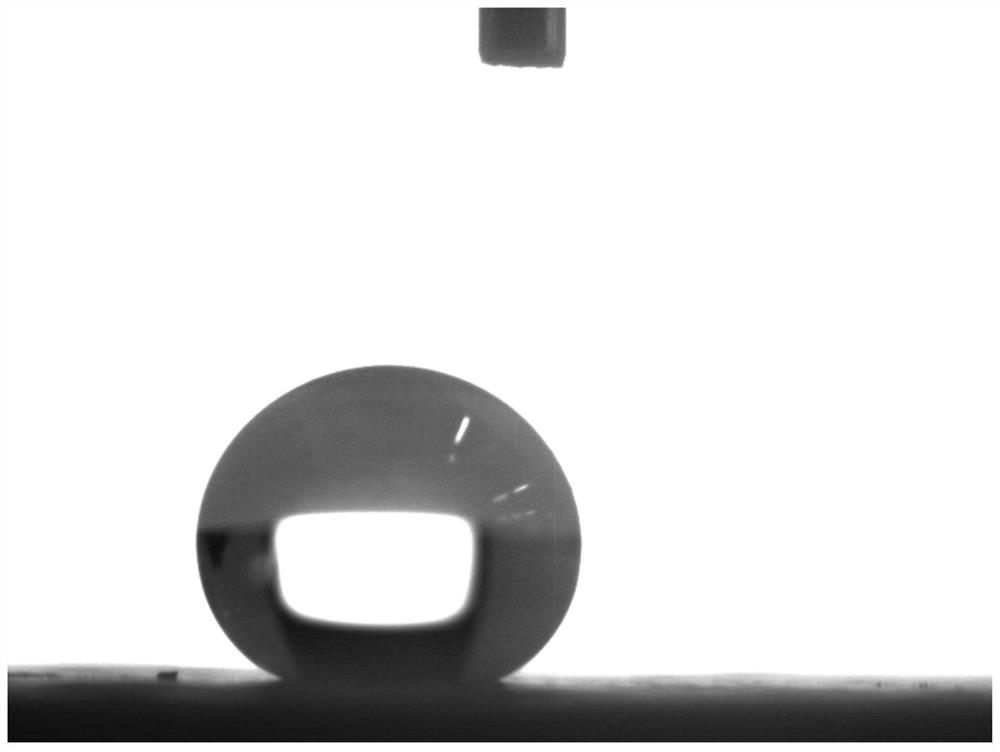

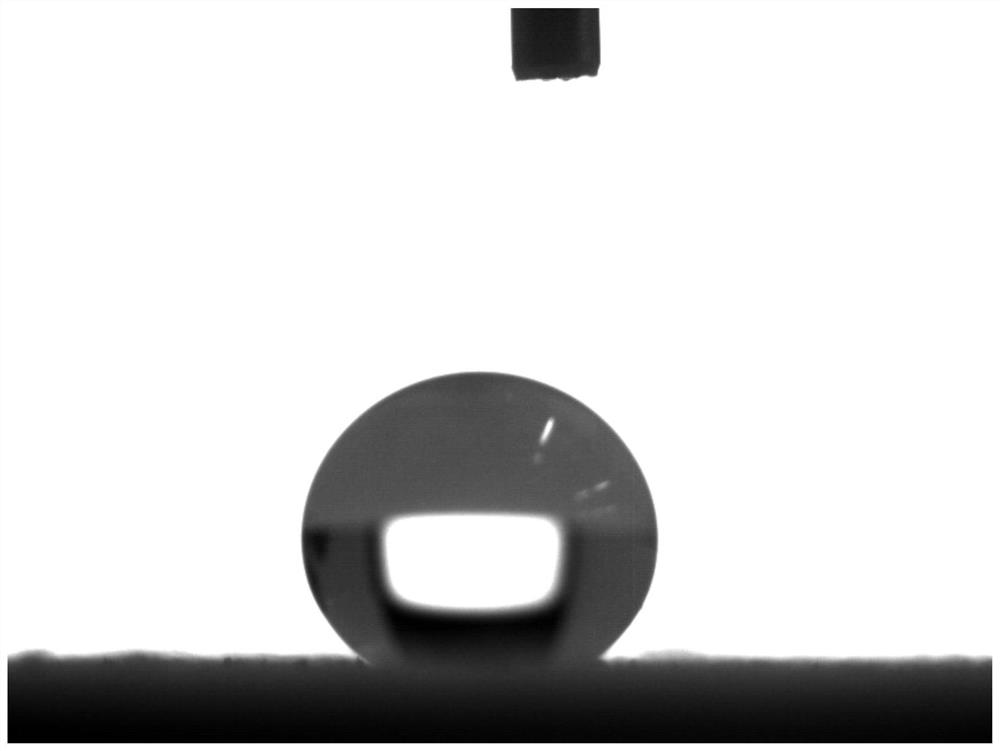

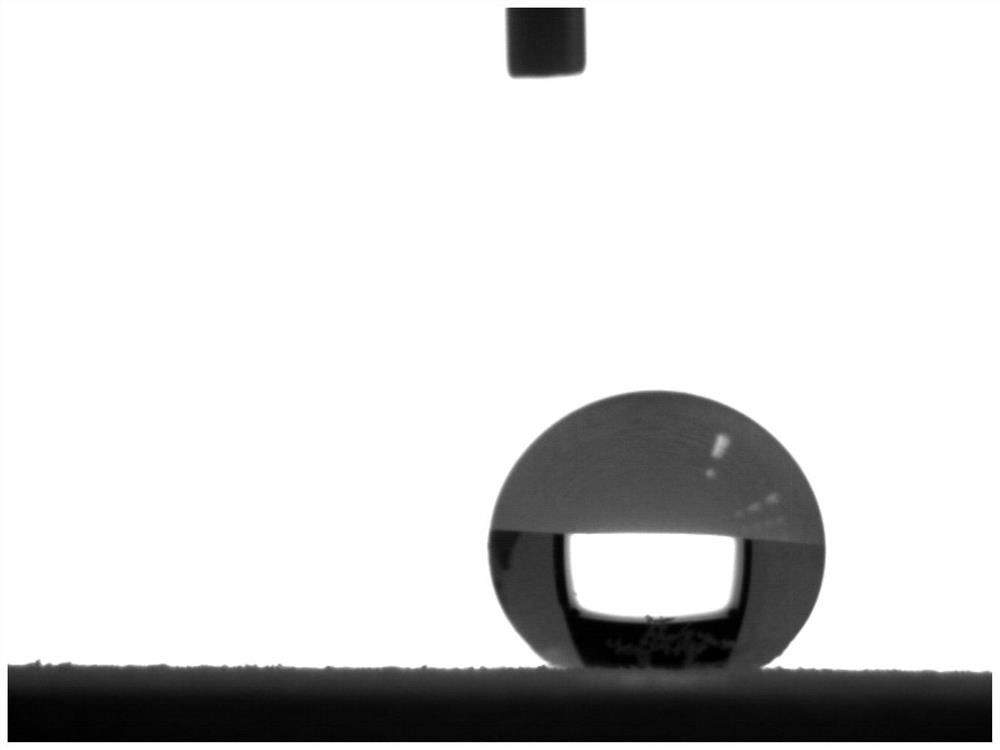

Image

Examples

Embodiment

[0030] Step 1. Prepare materials:

[0031] Mix boehmite nano powder, polydimethylsiloxane, platinum catalyst, bisphenol A type epoxy resin, and ethyl acetate to obtain coating component A.

[0032] A coating component B was obtained by mixing hydrogen-containing silicone oil, diethylenetriamine, and an adduct of butyl glycidyl ether.

[0033] Step 2. Add all the coating components A and B prepared in step 1 into the beaker, and then perform ultrasonic mixing for 3 minutes.

[0034] Step 3, then put the paint obtained in step 2 into the spray gun, and evenly spray it on the surface of the aluminum plate.

[0035] Step 4. Put the aluminum plate sprayed in step 3 into an oven, set the temperature of the oven at 60° C., and keep it warm for 2 hours, and then obtain a hydrophobic nano-ceramic coating.

[0036] Table 1 is the coating components of 8 groups of embodiments and the corresponding obtained coating properties. The unit of the content of each component in the table is g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com