Sulfur hexafluoride gas recovery and purification method and system

A sulfur hexafluoride gas, sulfur hexafluoride technology, applied in chemical instruments and methods, liquefaction, sulfur compounds and other directions, can solve the problems of low recovery rate and recovery purity, large consumption of liquid nitrogen, etc., to reduce consumption and recovery High purity, avoidance of recovery rate and the effect of a significant drop in recovery purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

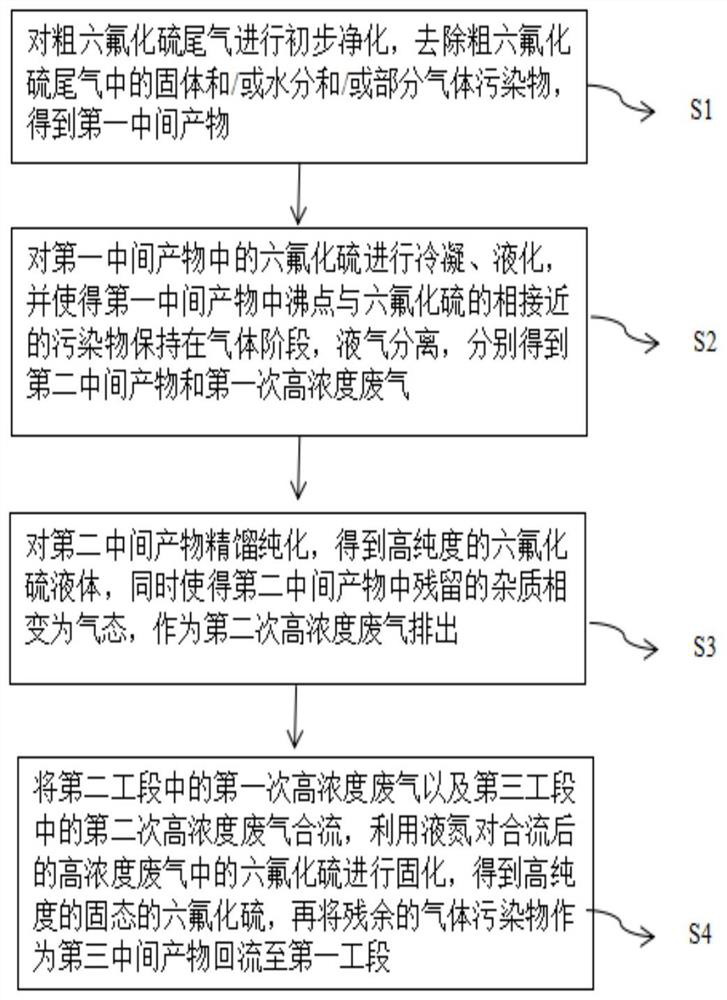

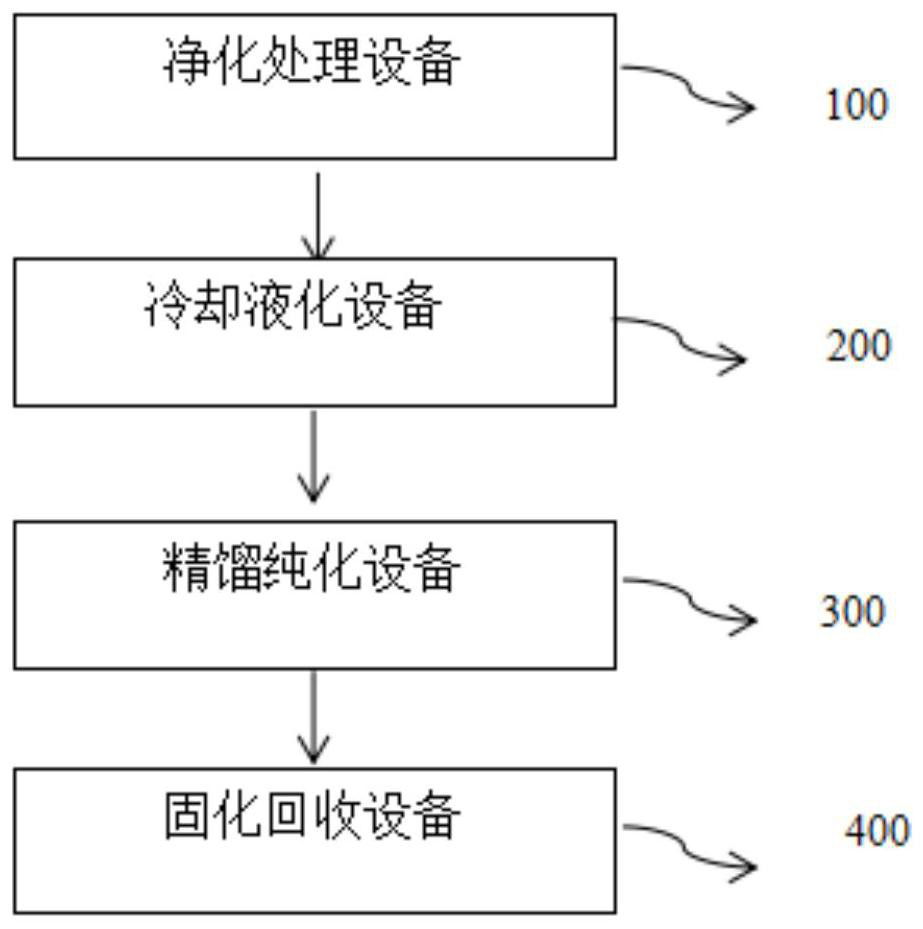

[0058] Such as figure 1 As shown, the present embodiment provides a method for recovering and purifying sulfur hexafluoride gas, comprising the following steps:

[0059] (1) The first section: performing preliminary purification on the crude sulfur hexafluoride tail gas, removing solids and / or moisture and / or some gas pollutants in the crude sulfur hexafluoride tail gas, and obtaining the first intermediate product.

[0060] It is worth noting that the crude sulfur hexafluoride tail gas described in this example is used sulfur hexafluoride, and the crude sulfur hexafluoride tail gas contains more impurities. Specifically in this embodiment, the impurities contained in the crude sulfur hexafluoride tail gas include air, moisture, CO 2 , one or more of solid impurity particles.

[0061] In the first section, the main purpose of the first section is to remove solid impurity particles and moisture in the crude sulfur hexafluoride tail gas. The concrete steps of described first ...

Embodiment 2

[0075] Basically with embodiment 1. Because the same device has a certain range requirement for the impurity content of crude sulfur hexafluoride, the reason is that the level of sulfur hexafluoride content determines its boiling point under a specific pressure. A bottle of recycled gas with 90% sulfur hexafluoride content and 30% sulfur hexafluoride recycled gas can have a difference of more than 30° in the recovered liquefaction or solidification temperature zone. This difference will lead to a significant decrease in the recovery rate and recovery purity of the device, and a significant increase in the consumption of liquid nitrogen. In order to avoid that the tail gas with different sulfur hexafluoride content enters the solidification tank and causes the recovery rate and recovery purity of the device to drop significantly, this embodiment further adds a fourth section on the basis of Example 1. The fourth section includes :

[0076](4) The fourth section: the first hig...

Embodiment 3

[0082] It is basically the same as Example 2. Since a refrigerant needs to be set in the shell of the cold recovery device to exchange heat with the high-concentration exhaust gas after confluence, in order to reduce the consumption of liquid nitrogen when the liquid nitrogen in the solidification tank is cooled; and for the solidification tank, each time the liquid nitrogen solidifies The waste gas after post-gasification must carry a part of cold energy. Therefore, in this embodiment, while the remaining gaseous pollutants with a boiling point close to that of sulfur hexafluoride are returned to the first section as the third intermediate product, the gasified waste gas is also sent into the The shell of the cold recovery device is used as a refrigerant for cold recovery, which can further greatly reduce the consumption of liquid nitrogen in the solidification section, and has the characteristics of low energy consumption, safety, and high economy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com