Co@In2O3/C composite photocatalyst as well as preparation method and application thereof

A catalyst and composite light technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problems of poor catalytic activity and fast electron-hole recombination rate , to achieve the effect of good reduction activity, easy control of preparation conditions and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of In-MIL-68: Weigh 500mg of indium nitrate hydrate [In(NO 3 ) 3 wxya 2 O] was dissolved in 150 mL of dimethylformamide (DMF) with stirring at room temperature, followed by the addition of 500 mg of terephthalic acid (C 8 h 6 o 4 ), stirred for 10 minutes to fully dissolve, and then stirred in an oil bath at 120°C for 120 minutes. After the reaction was completed and cooled to room temperature, it was centrifuged and washed 3 times with absolute ethanol, and the white precipitate was collected and vacuum-dried overnight at 60° C. to obtain the product.

[0029] (2) Preparation of ZIF-67: Weigh 1.82g cobalt nitrate hexahydrate [Co(NO 3 ) 2 6H 2 O] and 2.05g2-methylimidazole (C 4 h 6 N 2 ) were ultrasonically dissolved in 50 mL of methanol at room temperature, and then the 2-methylimidazole solution was added dropwise into the cobalt nitrate solution, and ultrasonicated at 25° C. for 15 min, and then stirred at 25° C. for 24 h. After the reacti...

Embodiment 2

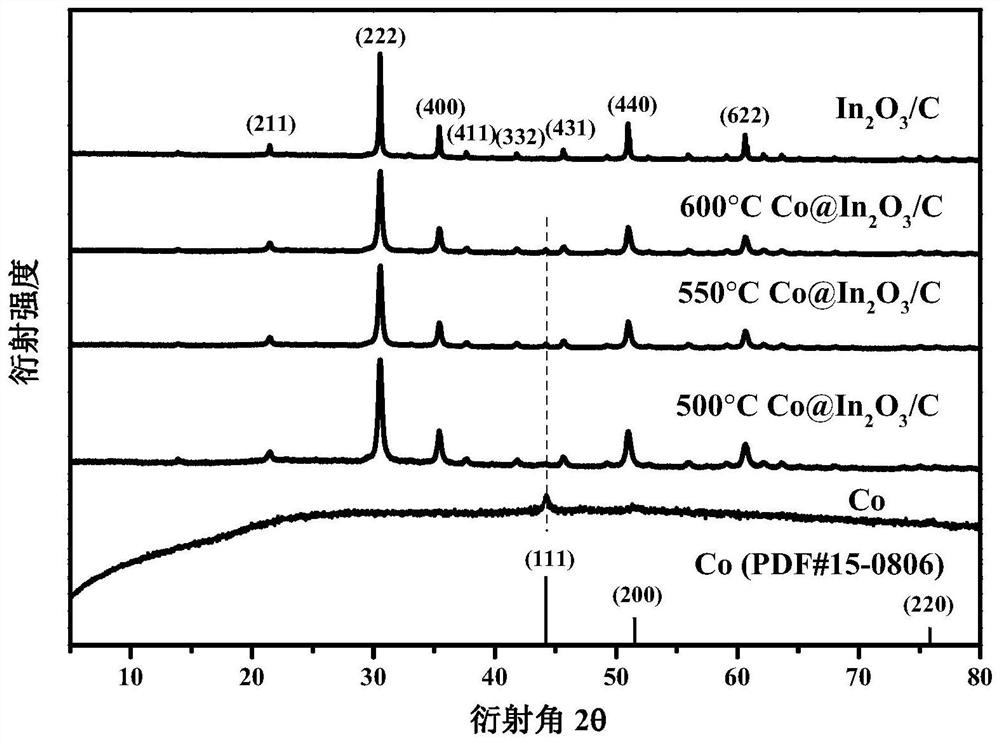

[0033] According to the method of Example 1, the calcination temperature of 550°C in step (4) was replaced by 500°C and 600°C to calcinate the ZIF-67@In-MIL-68 composite, and the other operations were the same as in Example 1 to prepare 500℃Co@In 2 o 3 / C and 600℃Co@In 2 o 3 / C composite catalyst.

[0034] 1. Crystal phase structure and morphology characterization of carbon dots-coated indium oxide nanotube composite photocatalysts grown in situ by MOF-derived cobalt nanoparticles:

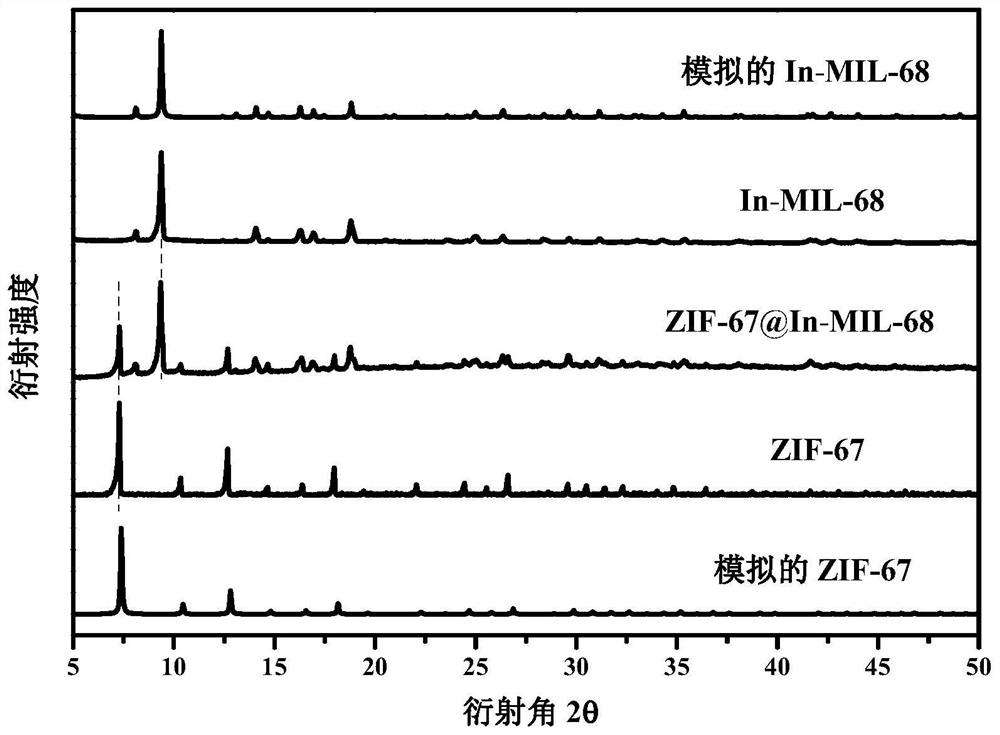

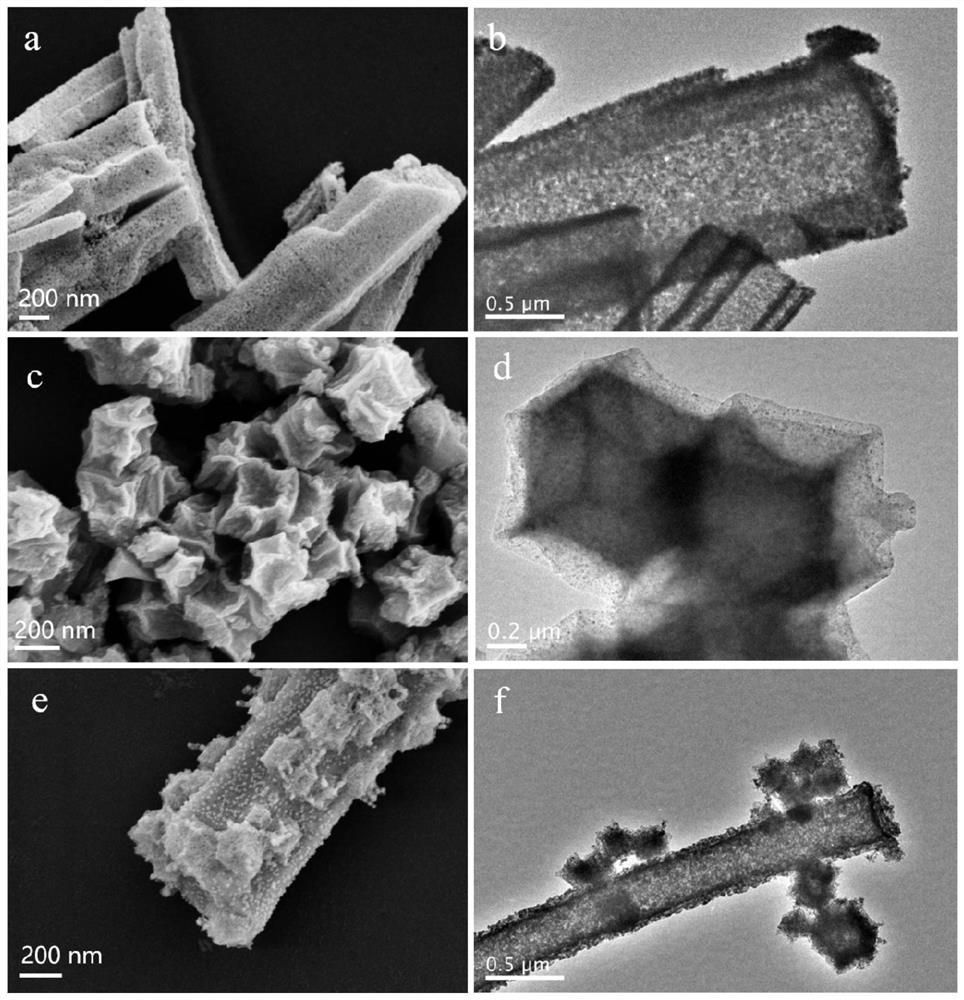

[0035] In-MIL-68, ZIF-67, ZIF-67@In-MIL-68 composites prepared in Examples 1 and 2, and the calcined product In 2 o 3 / C, Co, 500℃Co@In 2 o 3 / C, 550℃Co@In 2 o 3 / C and 600℃Co@In 2 o 3 The crystal phase structure of the / C photocatalyst was analyzed by X-ray diffractometer. X-ray diffraction pattern as Figure 1a As shown, the In-MIL-68 and ZIF-67 prepared in the experiment corresponded to the XRD diffraction peaks simulated by the software, indicating that the two MOFs were successful...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com