Bimetal composite catalyst, preparation method and application thereof, working electrode and battery system

A composite catalyst, working electrode technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as secondary pollution, achieve no secondary pollution, Simple operation, increased catalytic activity and effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention provides the preparation method of bimetallic composite catalyst described in above-mentioned technical scheme, comprises the following steps:

[0028] Mixing the carbon material, nitric acid solution and hydrochloric acid solution, and performing acid treatment to obtain acid-treated carbon material;

[0029] The first water-soluble metal salt, the second water-soluble metal salt and water are mixed to obtain a mixed bimetallic salt solution; the bimetallic ions in the mixed bimetallic salt solution include palladium ions, platinum ions, silver ions, gold ions, Two of ruthenium ions, iron ions, cobalt ions, nickel ions and copper ions;

[0030] immersing the acid-treated carbon material in the mixed double metal salt solution and drying to obtain a catalyst precursor;

[0031] The catalyst precursor is activated by plasma to obtain a bimetallic composite catalyst.

[0032] In the invention, the carbon material, nitric acid solution and hydrochlo...

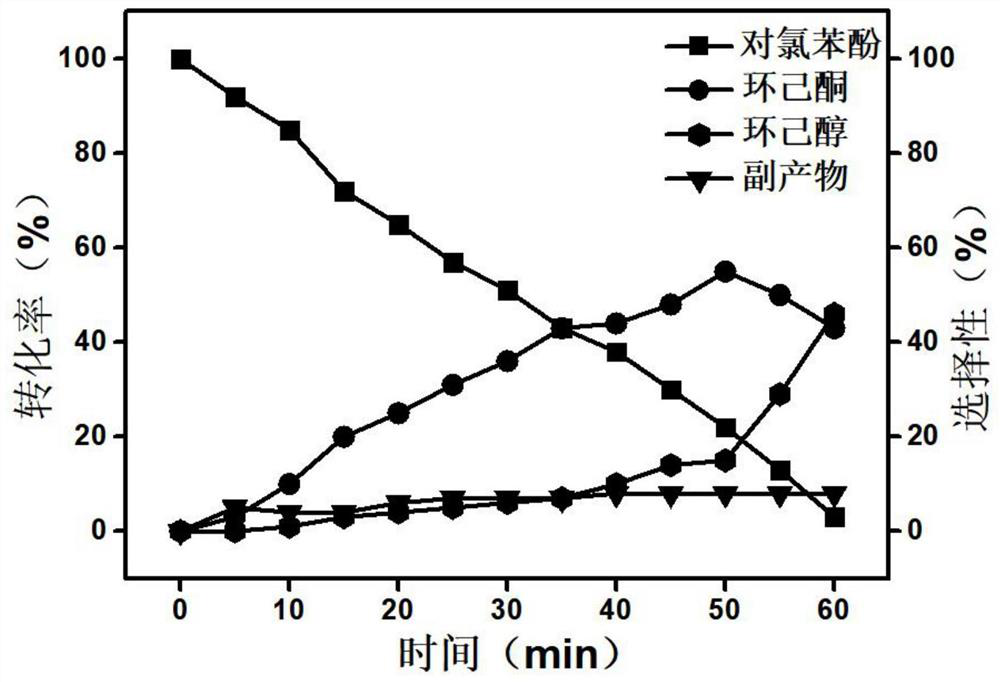

Embodiment 1

[0063](1) Mix 1 g of activated carbon, nitric acid solution (1mL, 2mol / L) and hydrochloric acid solution (3mL, 2mol / L), perform acid treatment and filter, and dry the obtained solid component at 80°C for 8h to obtain acid Treatment of activated carbon;

[0064] (2) Stir and mix palladium nitrate (10.85mg), chloroplatinic acid (13.27mg) and 30mL deionized water for 30min to obtain a mixed double metal salt solution;

[0065] (3) immerse 1 g of the acid-treated activated carbon and the mixed bimetallic salt solution obtained in step (2) at room temperature under stirring conditions for 12 hours, then place in a desiccator and dry at 120° C. for 12 hours to obtain a catalyst precursor;

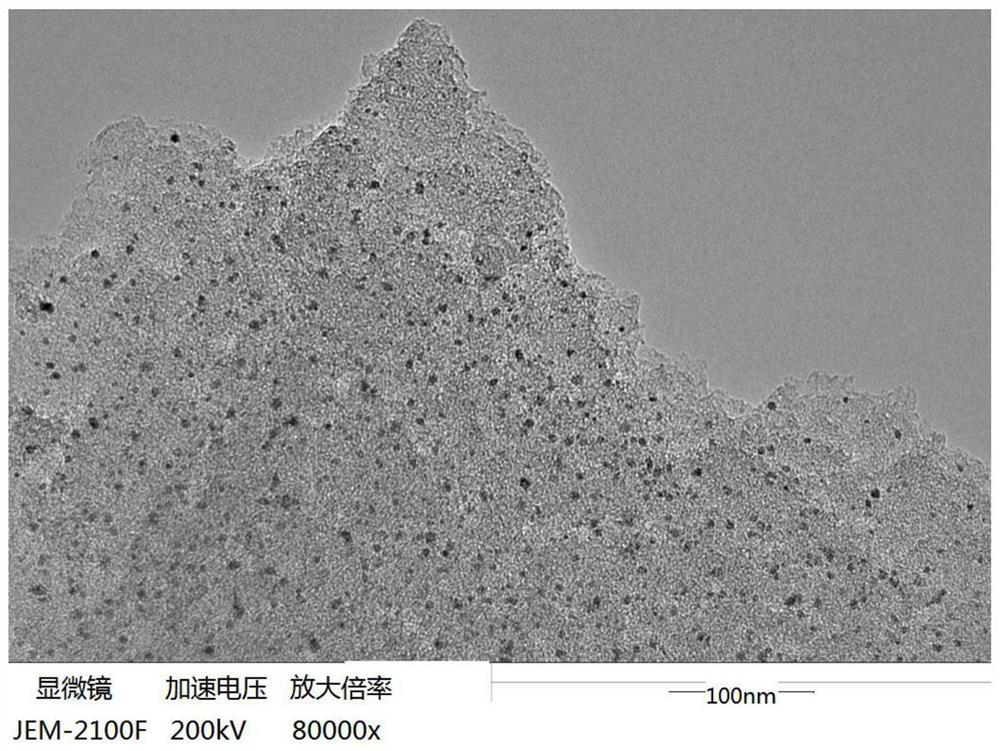

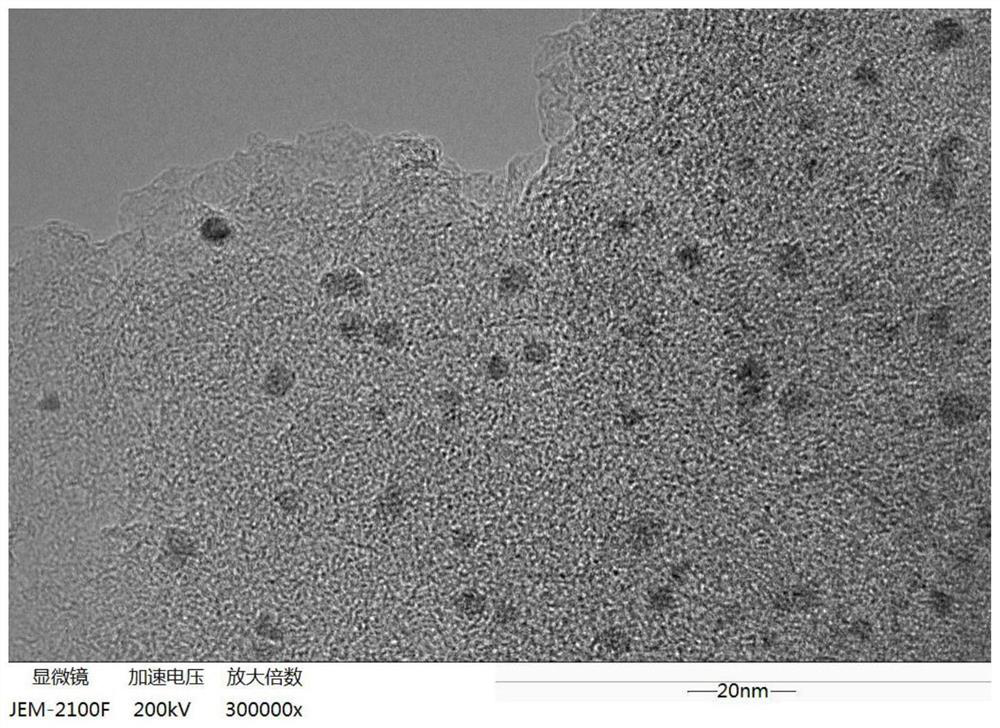

[0066] (4) The catalyst precursor is placed in a plasma reaction furnace, and hydrogen gas is introduced after vacuuming, and the plasma is activated for 0.5h at a temperature of 100°C, an electric power of 250W, and a vacuum of 80Pa to obtain a bimetallic Composite catalyst (abbreviated as PdPt...

Embodiment 2

[0075] (1) Mix 1g of carbon nanotubes, nitric acid solution (1mL, 2mol / L) and hydrochloric acid solution (3mL, 2mol / L), perform acid treatment and filter, and dry the obtained solid component at 80°C for 8h, Obtain acid-treated carbon nanotubes;

[0076] (2) Palladium nitrate dihydrate (10.85 mg), nickel nitrate hexahydrate (246.61 mg) and 30 mL of deionized water were stirred and mixed for 30 min to obtain a mixed double metal salt solution;

[0077] (3) Immerse 1 g of the acid-treated carbon nanotubes and the mixed double metal salt solution obtained in step (2) at room temperature and under stirring conditions for 12 hours, and then place them in a desiccator and dry them at 120° C. for 12 hours to obtain a catalyst precursor body;

[0078] (4) The catalyst precursor is placed in a plasma reaction furnace, and hydrogen gas is introduced after vacuuming, and the plasma is activated for 0.6h at a temperature of 100°C, a voltage of 350W, and a vacuum of 80Pa to obtain a bimet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com