Magnetic separation nanoparticle grafted NHPI catalyst, preparation method and application thereof

A nanoparticle and catalyst technology, applied in the field of catalysis, can solve problems such as affecting product quality, and achieve the effects of not easy to run off, simple and feasible preparation process, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

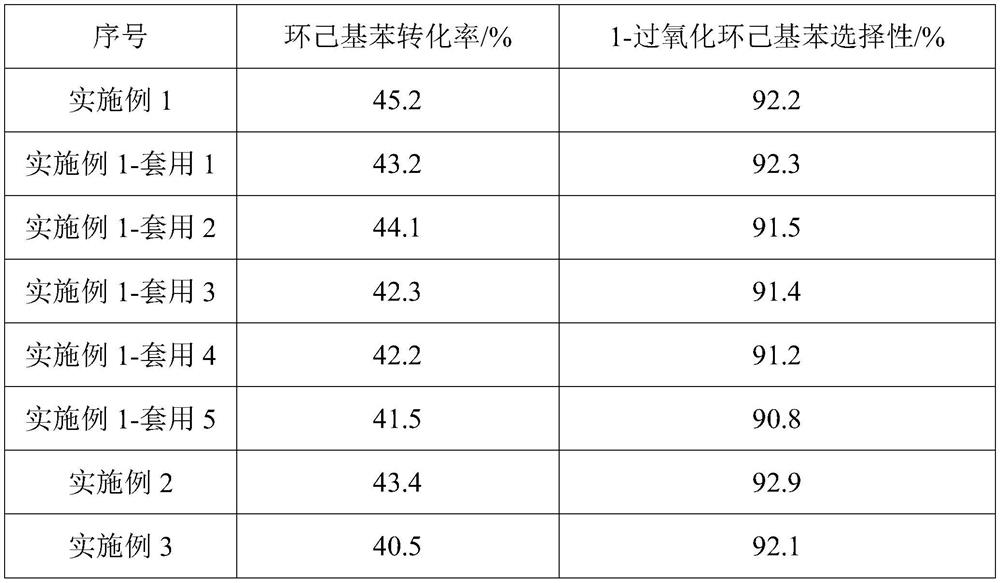

Embodiment 1

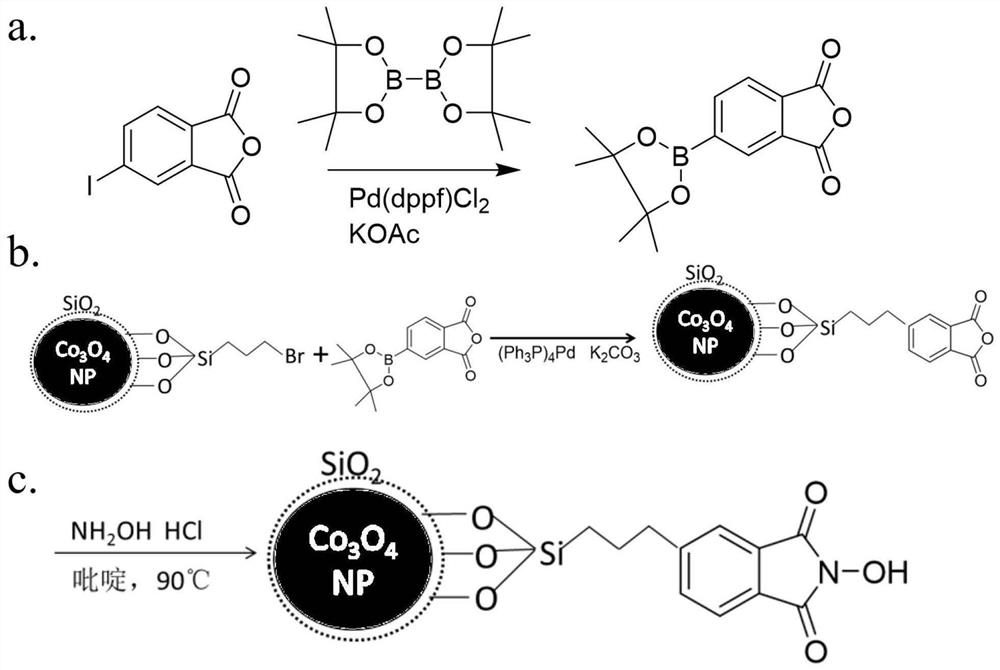

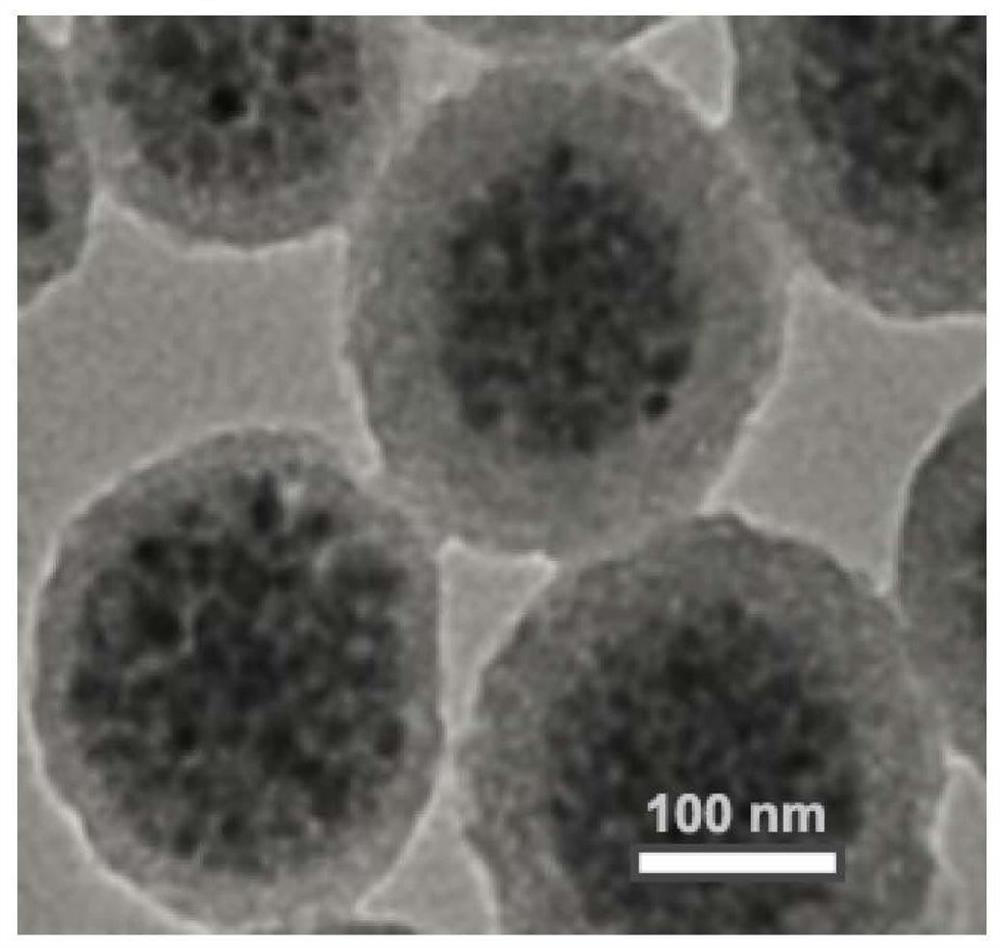

[0126] The present embodiment provides a kind of preparation method of the catalyst of magnetic separation nanoparticle grafting NHPI, such as figure 1 Shown, described preparation method comprises the steps:

[0127] (1) 100 g of an aqueous solution of 5% octadecyltrimethylammonium bromide and a magnetic metal source are mixed, and the magnetic metal source includes CoCl with a molar ratio of 1:1 3 (10g) and CoCl 2 (7.8g), be warming up to 80 ℃, dropwise add 50g alkali concentration and be the sodium hydroxide solution of 50wt%, carry out the first reaction 2h with stirring in nitrogen atmosphere, cool down to room temperature after the first reaction, successively through filtration, filter cake through The first washing with 60 g of water was repeated three times, and the solid phase was vacuum-dried at 50° C. for 4 hours to obtain the first magnetic particles;

[0128] Mix the first magnetic particles and 6.3g of tetraethyl silicate (0.03mol), first perform ultrasonic tr...

Embodiment 2

[0136] This embodiment provides a method for preparing a catalyst for magnetically separated nanoparticles grafted with NHPI, the preparation method comprising the following steps:

[0137] (1) 50 g of an aqueous solution of 10% cetyltrimethylammonium chloride and a magnetic metal source are mixed, and the magnetic metal source includes CoCl 3 (10g) and CoCl 2 (15g), be warming up to 90 ℃, dropwise add 50g alkali concentration and be the sodium hydroxide solution of 55wt%, carry out the first reaction 4h with stirring in nitrogen atmosphere, cool down to room temperature after the first reaction, successively through filtration, filter cake through 70g The first washing with water was repeated four times, and the solid phase was vacuum-dried at 30° C. for 8 hours to obtain the first magnetic particles;

[0138] Mix the first magnetic particles and 12.48g of tetraethyl orthosilicate (0.06mol), first perform ultrasonic treatment for 15min, then slowly add 35g of ammonia water w...

Embodiment 3

[0144] This embodiment provides a method for preparing a catalyst for magnetically separated nanoparticles grafted with NHPI, the preparation method comprising the following steps:

[0145] (1) 90 g of an aqueous solution of 10% octadecyltrimethylammonium bromide and a magnetic metal source are mixed, and the magnetic metal source includes CoCl 3 (20g) and CoCl 2 (25g), be warming up to 60 ℃, dropwise add 50g alkali concentration and be the potassium hydroxide solution of 40wt%, carry out the first reaction 20h with stirring in nitrogen atmosphere, cool down to room temperature after the first reaction, successively through filtration, filter cake through 65g The first washing with water was repeated three times, and the solid phase was vacuum-dried at 30° C. for 8 hours to obtain the first magnetic particles;

[0146] Mix the first magnetic particles and 50 g of tetraethyl silicate (0.24 mol), first perform ultrasonic treatment for 30 min, then slowly add 280 g of ammonia wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com