Superfine nano barium carbonate and preparation method thereof

An ultra-fine nano and barium carbonate technology, applied in the direction of barium carbonate, calcium carbonate/strontium/barium, nanotechnology, etc., can solve the problems of energy consumption, affecting the back-end application of barium carbonate powder, grain growth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention provides a method for preparing nano ultrafine barium carbonate, comprising the steps of:

[0031] A) The alcohol solution of barium hydroxide octahydrate and mixing, to give an alcohol solution of barium hydroxide octahydrate;

[0032] B) The alcohol solution of barium hydroxide octahydrate, and the reaction was stirred for dimethyl carbonate, the pH is ≤8, stirring was stopped by adding ammonia was allowed to stand to give a liquid mixture;

[0033] C) The mixture of the solid-liquid separation, dried, ultrafine nano barium carbonate.

[0034] Step a) in:

[0035] In certain embodiments of the present invention, the alcohol solution of the alcohol include ethylene glycol or glycerol; the alcohol solvent in the solution is water.

[0036] In certain embodiments of the present invention, the alcohol solution, the volume ratio of alcohol to water is 0.4 to 15: 1. In certain embodiments, the alcohol solution, the volume ratio of alcohol to water is 15: 1...

Embodiment 1

[0064] 1) 468.75 ml of ethylene glycol and 31.25 ml of water were mixed to obtain a glycol solution, and an octohydride is dissolved to give an alcohol solution having a mass concentration of 6% octhyde hydroxide;

[0065] 2) In the alcohol solution of the octamite in the octohydrofluide, the molar ratio of dimethyl carbonate and octhyde hydroxide is 1: 1 at a rate of 3 g / min, and stirred at normal temperature. The reaction, the pH was stopped at 7 to 8, and the mixture was added, and ammonia water (in the stirred solution, the amount of ammonia was 1 vol%) was allowed to stand, resulting in a mixture liquid;

[0066] 3) The mixture was separated, and the material after centrifugation was washed twice with water, and ethanol was purified twice, and the purity was 99.9% ultrafine nanocarbonate. Bismuth.

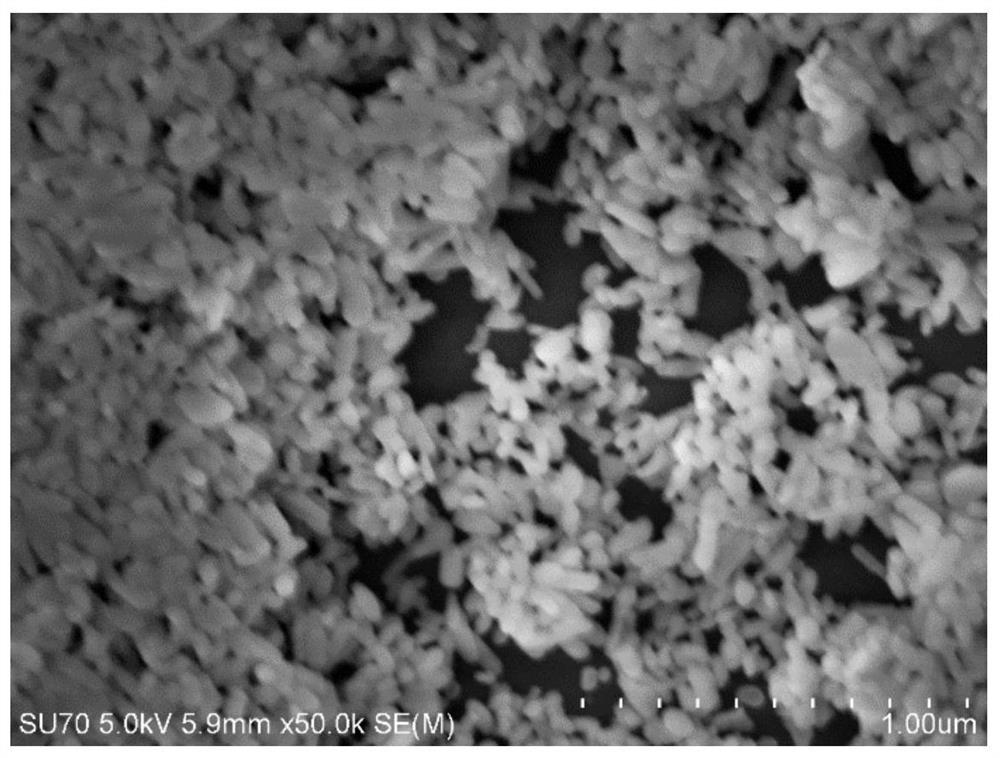

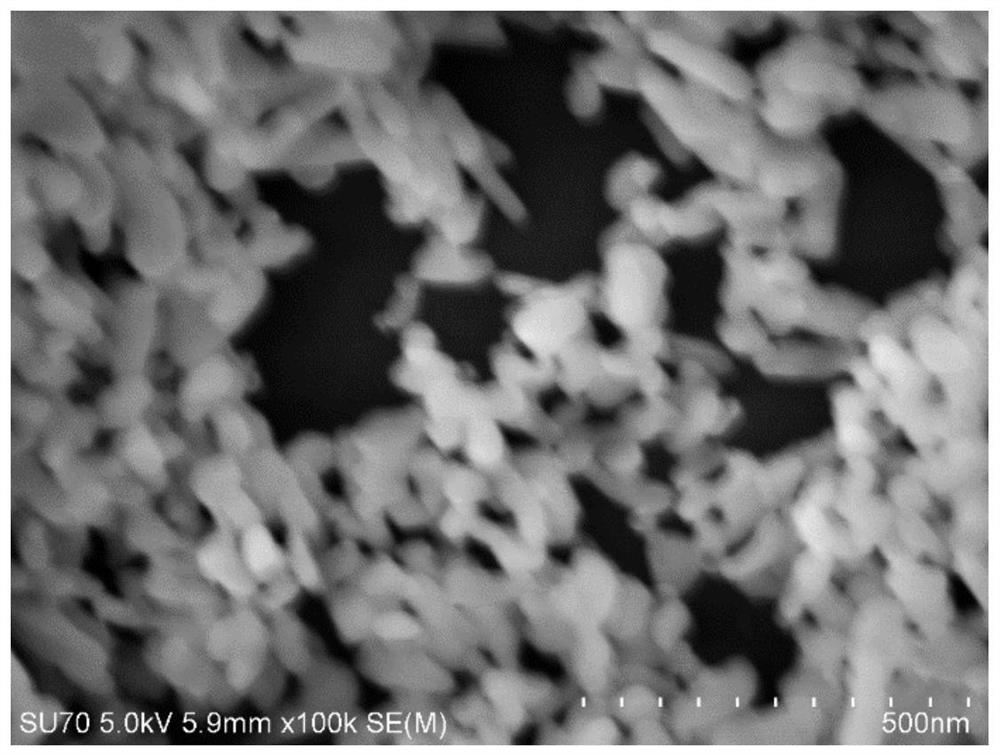

[0067] In this embodiment, the obtained ultrafine nanocarbonate is scanned electron microscopy, as a result, figure 1 and figure 2 Indicated. figure 1 The SEM diagram of the ult...

Embodiment 2

[0069] 1) 450 ml of ethylene glycol with 50 ml of water to obtain an ethylene glycol solution, and octose hydroxide is dissolved, and an alcohol solution having a mass concentration of 3% octohydride;

[0070] 2) In the alcohol solution of the octamite in the octohydrocarbon hydroxide, the molar ratio of dimethyl carbonate and octhyde is 0.5: 1, stirring at normal temperature. The reaction, the pH was stopped at 7 to 8, and the mixture was added, and an ammonia water (in the stirred solution, the amount of ammonia was 5 vol%) was allowed to allow the mixture liquid;

[0071] 3) The mixture was separated, and the material after centrifugation was washed twice with water, and ethanol was washed twice, and the purity was 99.7% ultrafine nanocarbonate.

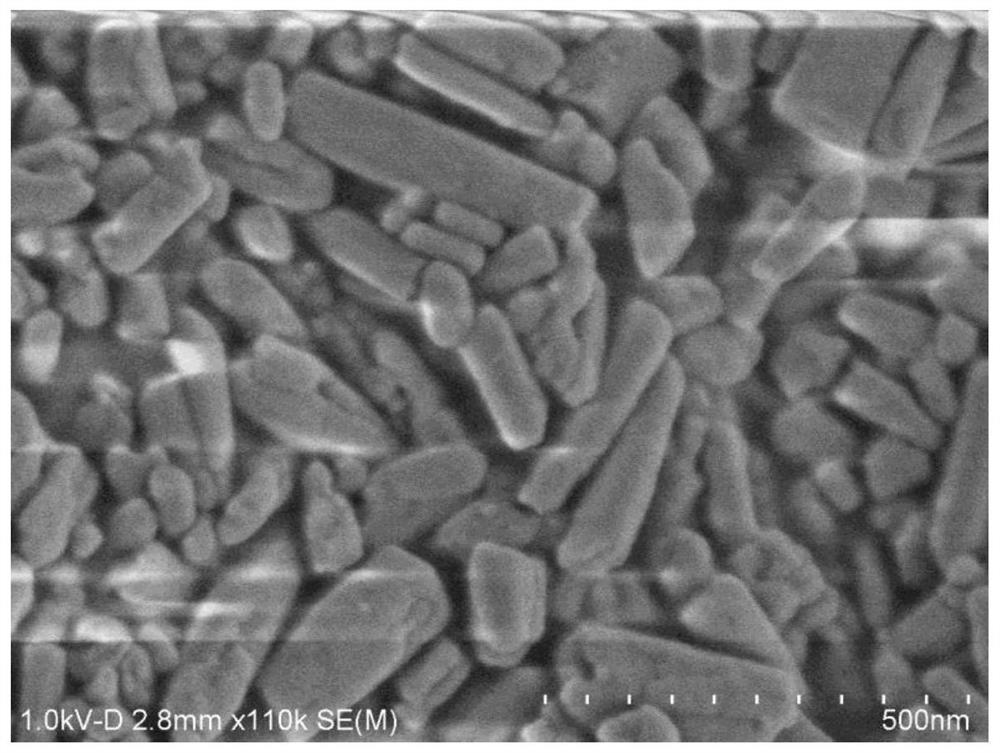

[0072] The ultrafine nanocarbonate was scanned electron microscopy, and the experimental results show that the grain size of the ultrafine nanocarbonate is 35 to 50 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com