High-temperature-resistant block polysulfate and preparation method thereof

A technology of polysulfate and high temperature resistance, applied in the field of high temperature resistant block polysulfate and its preparation, can solve the problem of unmatched heat resistance, achieve improved heat resistance, mild and easily controllable reaction conditions, and increased application temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

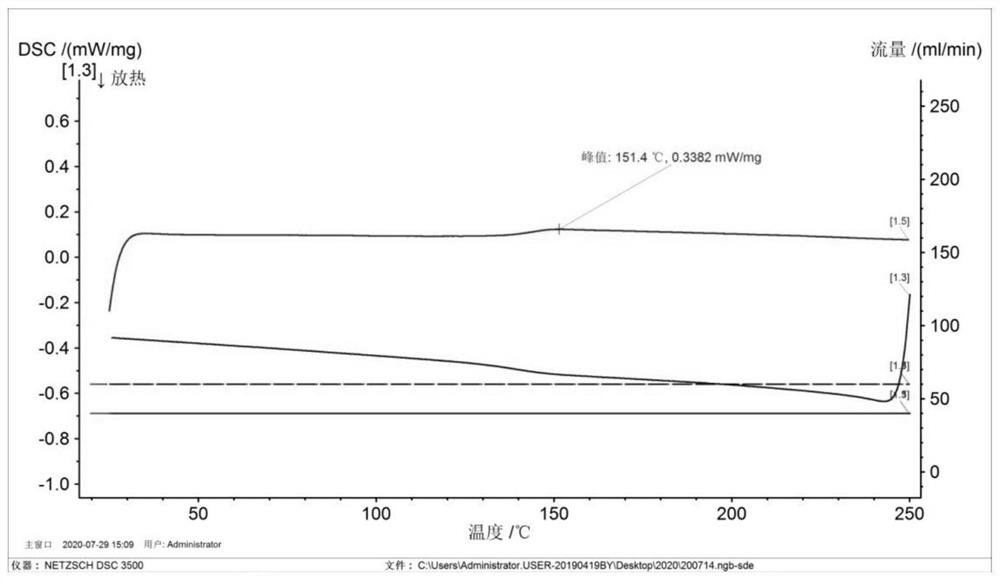

[0042] Embodiment 1: A synthetic method

[0043] Add 4g of bisphenol A, 6.88g of bisphenol A bissulfonyl fluoride, 25ml of sulfolane, and 5.32g of potassium carbonate into a reaction bottle with a high-efficiency stirrer at one time, and react at 170°C for 4 hours; once in another reaction bottle Add 4g of bisphenol A, 4.86g of 1,5-dichloroanthraquinone, 5.32g of potassium carbonate, and 25ml of sulfolane, and react at 170°C for 4 hours, then combine the two systems together and continue to react for 4 to 10 hours. Pour into water for precipitation to obtain the final block polysulfate, Mn=31018g / mol, Tg=151.4°C.

Embodiment 2

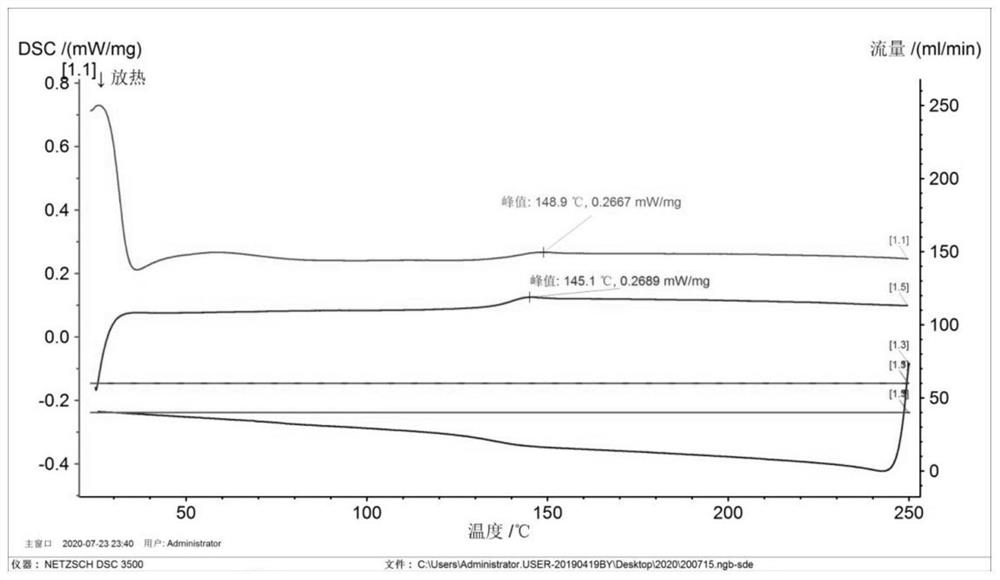

[0044] Embodiment 2: A synthetic method

[0045] Add 4g of bisphenol A, 7.56g of bisphenol A bissulfonyl fluoride, 25ml of sulfolane, and 5.32g of potassium carbonate into a reaction bottle with a high-efficiency stirrer at one time, and react at 170°C for 4 hours; Add 4.4g of bisphenol A, 4.86g of 1,5-dichloroanthraquinone, 5.32g of potassium carbonate, and 25ml of sulfolane, and react at 170°C for 4 hours, then combine the two systems together and continue the reaction for 4 to 10 hours. Pour into water for precipitation to obtain the final block polysulfate, Mn=19873g / mol, Tg=145.1°C.

Embodiment 3

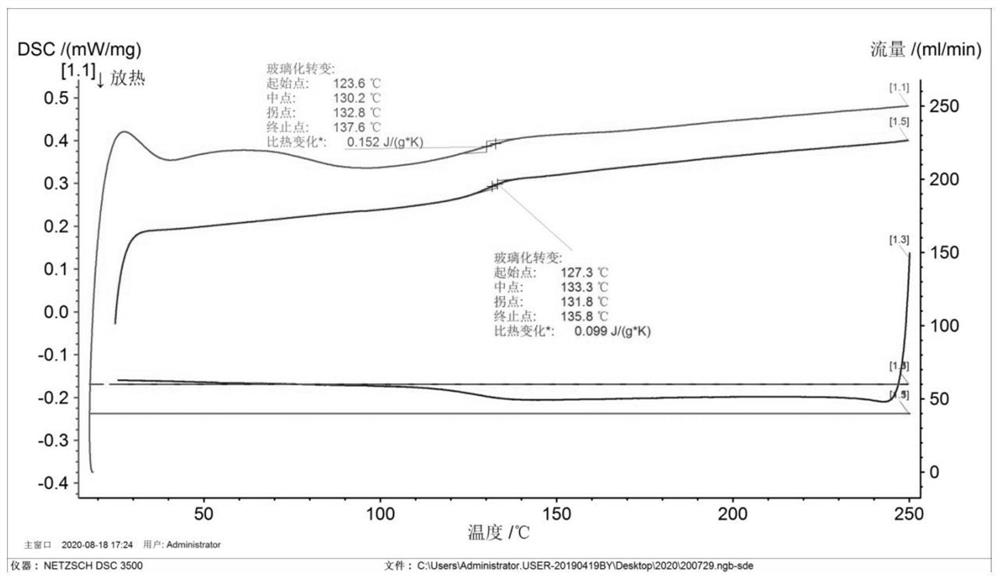

[0046] Embodiment 3: A synthetic method

[0047] Add 4.56g of bisphenol A, 9.8g of bisphenol A bissulfonyl fluoride, 34ml of sulfolane, and 6.08g of potassium carbonate into a reaction flask with a high-efficiency stirrer at one time, and react at 170°C for 4 hours; Add 5.7g bisphenol A, 5.54g 1,5-dichloroanthraquinone, 6.08g potassium carbonate, 34ml sulfolane, react at 170°C for 4 hours, then combine the two systems together and continue the reaction for 4-10 hours. The system was poured into water for precipitation to obtain the final block polysulfate, Mn=25219g / mol, Tg=131.8°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com