Natural partition lanthanum cerium oxide reflective heat-preservation coating and preparation method thereof

A technology of reflective heat-insulating coating and lanthanum cerium oxide, which is applied in the direction of reflection/signal coating, multi-color effect coating, anti-fouling/underwater coating, etc. Improve pollution, improve reflectivity, reduce the effect of building surface and internal temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

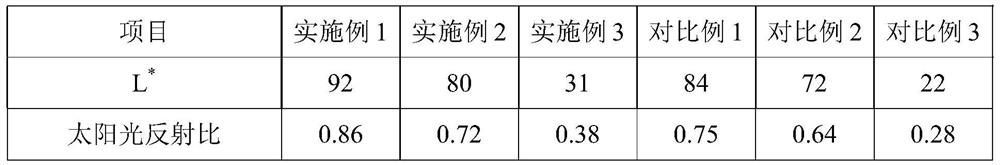

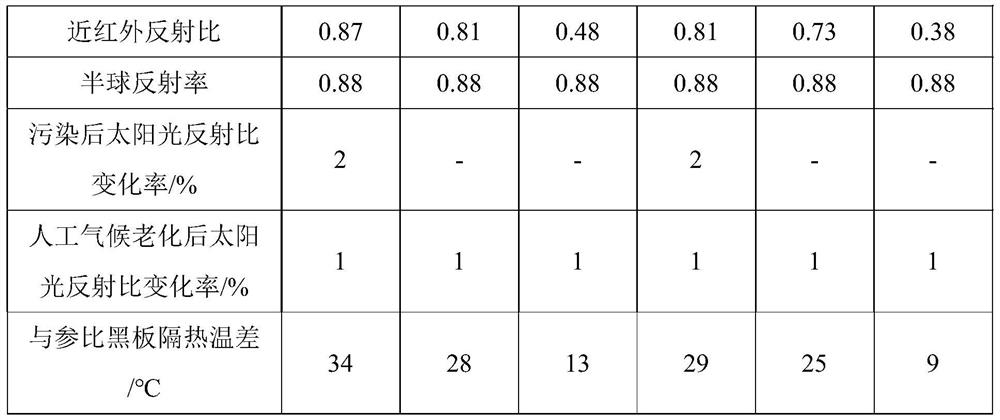

Examples

Embodiment 1

[0032] The preparation method of primer comprises the steps:

[0033] Stir and pre-disperse 175 g of deionized water, 8 g of predispersant, and 450 g of naturally distributed lanthanum cerium oxide, and grind for 15 minutes with a sand mill until the naturally distributed lanthanum cerium oxide D (90) in the slurry is 1.0 μm. The above slurry was mixed with 300g of water-based pure acrylic emulsion, 8g of dispersant, 5g of wetting agent, 2.5g of defoamer, 1.5g of multifunctional auxiliary agent, 35g of film-forming auxiliary agent, and 3g of thickener in a disperser, Control the line speed at 8m / s, stir for 35 minutes, add 2.0g of pH adjuster, and stir for 5 minutes to obtain the natural partition lanthanum cerium oxide reflective thermal insulation paint primer.

[0034] The preparation method of topcoat comprises the steps:

[0035] 200g of deionized water, 6g of pre-dispersant, 80g of nickel titanate infrared reflective pigment, 320g of naturally distributed lanthanum ceri...

Embodiment 2

[0039] The preparation method of primer is with embodiment 1.

[0040] The preparation method of topcoat comprises the steps:

[0041] Stir and pre-disperse 300g of deionized water, 18g of pre-dispersant, 200g of ultramarine blue pigment, and 200g of naturally distributed lanthanum cerium oxide, and grind for 10 minutes with a sand mill until the particle size D (90) of the pigment in the slurry is 1.5 μm. Mix the blue slurry with 280g of water-based pure acrylic emulsion, 6g of dispersant, 5g of wetting agent, 5.5g of defoamer, 3.5g of multifunctional additive, 33g of film-forming additive, and 5g of thickener in the disperser with high-speed stirring , the line speed was controlled at 8m / s, stirred for 35 minutes, 2.5g of pH regulator was added, and stirred for 5 minutes to obtain brick red reflective heat insulation paint finish B.

[0042]The test sample is first sprayed with a layer of primer with a thickness of 0.1mm to 0.15mm, and then sprayed with a layer of topcoat B...

Embodiment 3

[0045] The preparation method of primer is the same as embodiment 1.

[0046] The preparation method of topcoat comprises the steps:

[0047] Stir and pre-disperse 300 g of deionized water, 8 g of pre-dispersant, 50 g of iron oxide black pigment, and 250 g of naturally distributed lanthanum cerium oxide, and grind for 10 minutes with a sand mill until the particle size D (90) of the pigment in the slurry is 1.3 μm. The above blue slurry, 300g of water-based pure acrylic emulsion, 8g of dispersant, 5g of wetting agent, 5.5g of defoamer, 3.5g of multifunctional auxiliary agent, 28g of film-forming auxiliary agent, and 3g of thickener are stirred at high speed in the disperser Mixing, the line speed is controlled at 8m / s, stirring for 35 minutes, adding 2.5g of pH regulator, stirring for 5 minutes to obtain the blue reflective thermal insulation coating topcoat C.

[0048] The test sample is first sprayed with a layer of primer with a thickness of 0.1mm to 0.15mm, and then spray...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com