Normal-pressure drying preparation method and application of polyimide aerogel product

A polyimide, atmospheric drying technology, used in textiles and papermaking, one-component synthetic polymer rayon, chemical post-processing of synthetic polymer rayon, etc. The problem of high cost, to achieve the effect of low cost, simple preparation process and reduced volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Preparation of copolymerized polyimide:

[0043] Under nitrogen protection, in a three-neck round bottom flask, add 3,5-diaminobenzoic acid (DABA, 0.7608g), 4,4-diaminodiphenyl ether (ODA, 1.001g) and N-methylpyrrolidone in sequence (NMP, 25 ml), mechanically stirred until DABA and ODA were completely dissolved, then added 4,4'-(hexafluoroisopropene) diphthalic anhydride (6FDA, 4.4423 g), reacted at 25 °C for 24 h, and raised the temperature to 120 °C Heat preservation reaction for 1 hour, continue to heat up to 160°C for heat preservation reaction for 1 hour, continue to heat up to 190°C for heat preservation reaction for 12 hours, and obtain a soluble polyimide solution.

[0044] (2) Preparation of polyimide grafted with hydroxyethyl methacrylate:

[0045] Hydroxyethyl methacrylate (HEMA, 5 mmol, 0.65 g), N , N '-dicyclohexylcarboimide (5 mmol, 1.03 g) and 4-dimethylaminopyridine (0.50 mmol, 0.0608 g) and stirred until the solid disappeared, added to the above-m...

Embodiment 2

[0051] The difference from Example 1 is that the amount of grafted hydroxyethyl methacrylate is 50%, that is, hydroxyethyl methacrylate (HEMA, 2.5 mmol, 0.325 g), N , N '-bicyclic Hexylcarbimide (2.5 mmol, 0.515 g) and 4-dimethylaminopyridine (0.25 mmol, 0.0304 g), and the obtained polyimide airgel fiber was designated as HFPI-50.

Embodiment 3

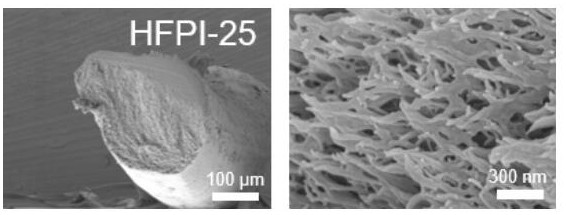

[0053] The difference from Example 1 is that the amount of grafted hydroxyethyl methacrylate is 25%, that is, hydroxyethyl methacrylate (HEMA, 1.25 mmol, 0.1625 g), N, N '-bicyclic Hexylcarbimide (1.25 mmol, 0.2575 g) and 4-dimethylaminopyridine (0.125 mmol, 0.0152 g), and the obtained polyimide airgel fiber was designated as HFPI-25.

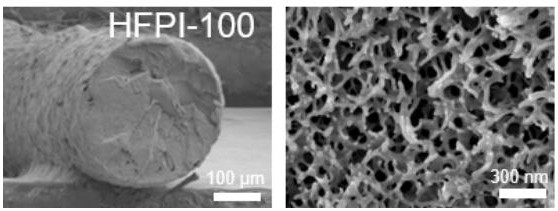

[0054] figure 1 It is a scanning electron microscope image of the polyimide airgel fiber of Example 1. It can be seen that the cross section of the fiber presents a regular circle, and it can be seen from the enlarged scanning electron microscope that the interior presents a three-dimensional porous structure.

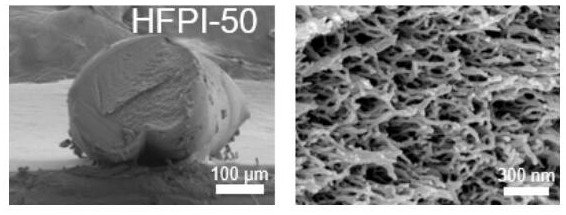

[0055] figure 2 It is the scanning electron micrograph of the polyimide airgel fiber of embodiment 2, and fiber presents pea shape, and internal hole skeleton is bonded together, and this is because only 50% of the hydroxyethyl methacrylate of grafting, wet gel The low cross-linking density leads to the collapse and shrinkage of the sk...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com