Automobile chassis protective agent and preparation method thereof

A technology of automobile chassis and protective agent, which is applied in the direction of anti-corrosion coatings, fire-proof coatings, coatings, etc., can solve the problems of shortening the service life of vehicles, damage to automobile chassis, etc., to improve stone chip resistance and rust resistance, and improve adhesion , The effect of high softening point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

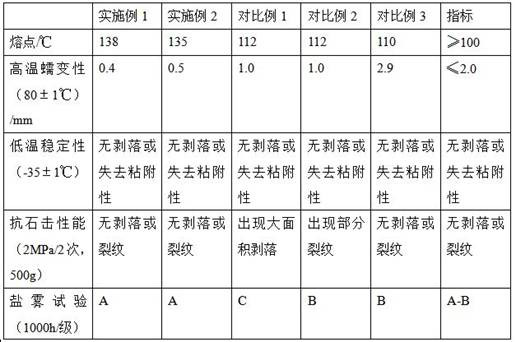

Examples

Embodiment 1

[0018] An automobile chassis protectant, which is parts by weight of the feed composition: 100 parts of paraffin wax; 30 parts of microcrystalline wax; 4 parts of polyethylene wax; MMT 4 parts; 6 parts of urethane acrylate resin; sulfonate type rust agent 3 parts, 2 parts of calcium salt rust inhibitor, 3 parts of nonionic rust agent, 4 parts of a phenolic antioxidant, is the use of the modified montmorillonite modified sodium montmorillonite obtained CTAB ; wherein the sulfonate type rust preventive agent is sodium petroleum sulfonate, calcium salt rust inhibitor is a calcium petroleum sulfonate, non-ionic anti-rust agent is sorbitan monooleate, phenolic antioxidant is 2, di-t-butyl-p-cresol.

[0019] In this embodiment, the modified montmorillonite prepared as follows: the ultrasonic dispersion 100mg of sodium montmorillonite in deionized water, and a pH of 11 with sodium carbonate and, after standing to give a magnetic stir 1.5h Mongolian bentonite suspension was then warmed to...

Embodiment 2

[0022] An automobile chassis protectant, which is parts by weight of the feed composition: 90 parts of paraffin wax; microcrystalline wax 28 parts; 3 parts of polyethylene wax; MMT 2 parts; 8 parts urethane acrylate resin; sulfonate type 2 parts of a rust inhibitor, a rust inhibitor parts calcium salt, 3 parts of nonionic type rust preventive, 3 parts of phenolic antioxidant, is the use of the modified montmorillonite modified sodium montmorillonite obtained CTAB ; wherein the sulfonate type rust preventive agent is sodium petroleum sulfonate, calcium salt rust inhibitor is a calcium petroleum sulfonate, non-ionic anti-rust agent is sorbitan monooleate, phenolic antioxidant is 2, di-t-butyl-p-cresol.

[0023] In this embodiment, the modified montmorillonite prepared as follows: the ultrasonic dispersion 100mg of sodium montmorillonite in deionized water, and a pH of 11 with sodium carbonate and, after standing to give a magnetic stir 1.5h Mongolian bentonite suspension was then wa...

Embodiment 3

[0026] An automobile chassis protectant, which is parts by weight of the feed composition: 100 parts of paraffin wax; 20 parts of microcrystalline wax; 6 parts of polyethylene wax; 4 parts of MMT; 8 parts urethane acrylate resin; sulfonate type 2 parts of a rust inhibitor, rust inhibitor 2 parts of calcium salt, 2 parts of nonionic rust agent, 4 parts of a phenolic antioxidant, is the use of the modified montmorillonite modified sodium montmorillonite obtained CTAB ; wherein the sulfonate type rust preventive agent is sodium petroleum sulfonate, calcium salt rust inhibitor is a calcium petroleum sulfonate, non-ionic anti-rust agent is sorbitan monooleate, phenolic antioxidant is 2, di-t-butyl-p-cresol.

[0027] In this embodiment, the modified montmorillonite prepared as follows: the ultrasonic dispersion 100mg of sodium montmorillonite in deionized water, and a pH of 11 with sodium carbonate and, after standing to give a magnetic stir 1.5h Mongolian bentonite suspension was then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com