Curable composition and optical material comprising same

A technology of optical materials and compositions, applied in optics, optical components, optical components, etc., can solve problems such as high refractive index, high Abbe number, thermal deformation, etc., and achieve high refractive index, high glass transition temperature, less deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0078] Preparation Example: Preparation of Sulfur-Containing Organic Particles A

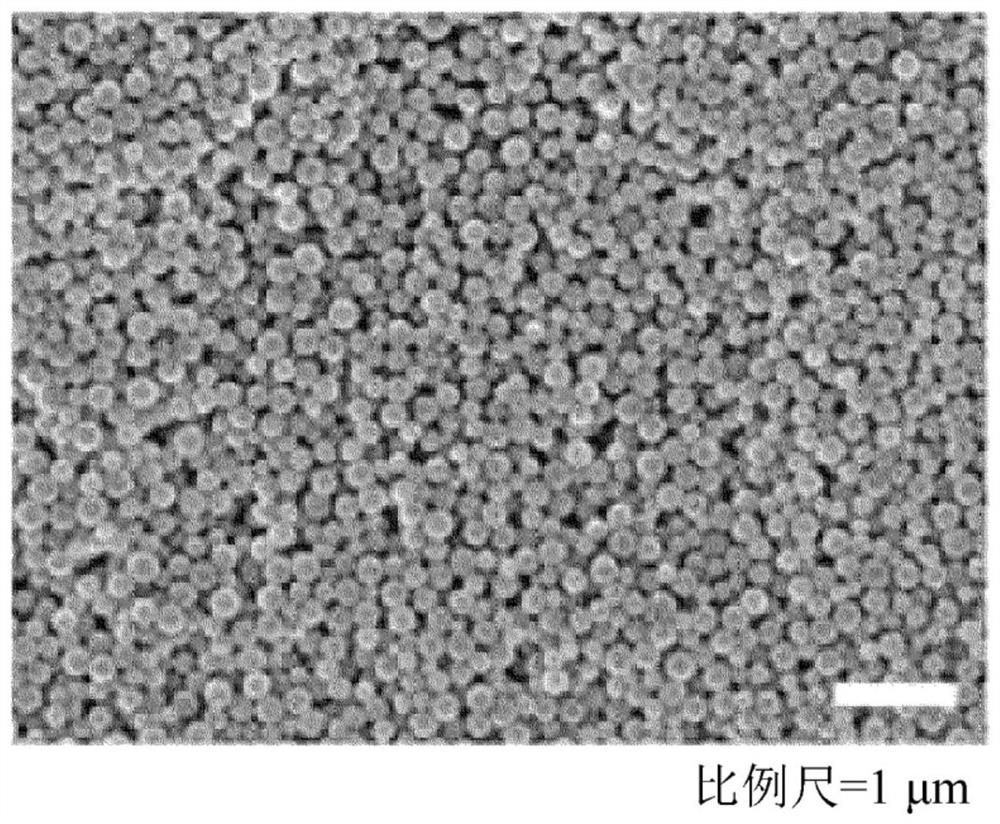

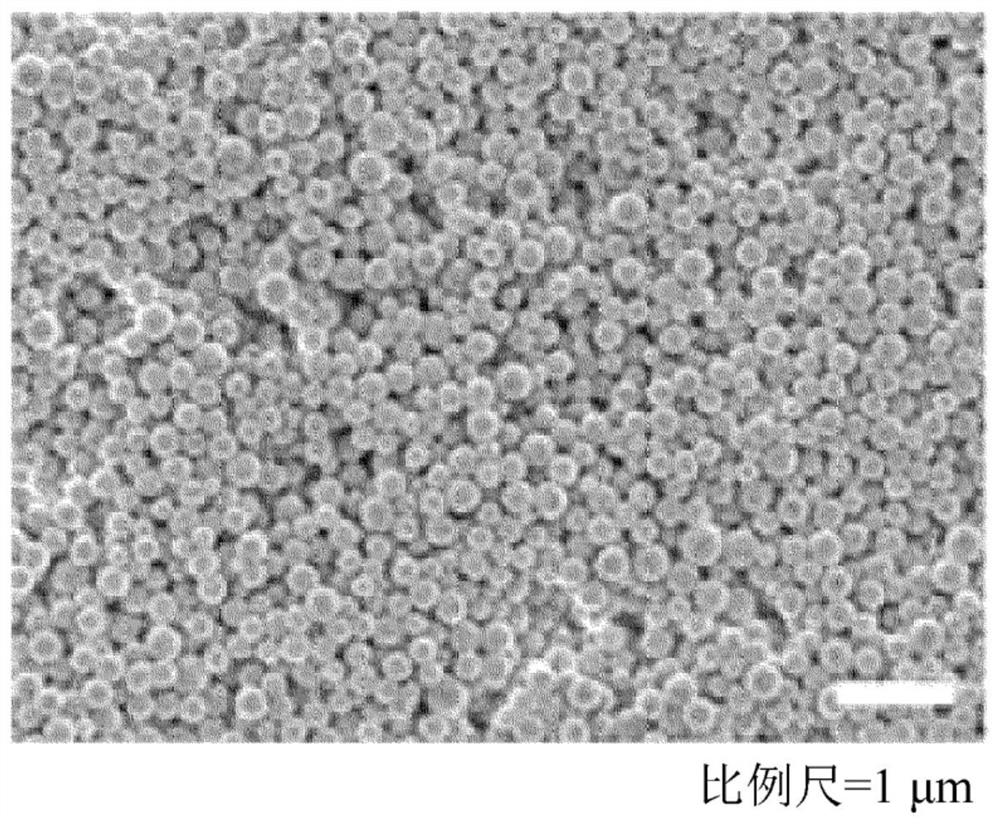

[0079] 100 ml of triple distilled water was placed in a 250 mL round bottom flask and degassed with argon (Ar) gas for 2 h. Then, the 20 ml vial was sealed with a septum and replaced with argon (Ar) gas, and the contained oxygen (O 2 ) gas, and this process was repeated three times. Introduce 2.401g sodium sulfide nonahydrate (Na 2 S·9H 2 O) and 961.98mg sulfur (S 8 ), and 8 mL of degassed distilled water were added, and the reaction solution was heated to 30° C. and stirred for 12 hours. After the reaction was over, 2 mL of degassed distilled water was added to prepare polysulfide (Na 2 S 4 ) aqueous solution. Among them, the preparation of polysulfide (Na 2 S 4 ) aqueous solution is as follows, and figure 1 is a photograph taken by scanning electron microscopy of the prepared aqueous polysulfide solution.

[0080] [Reaction 1]

[0081]

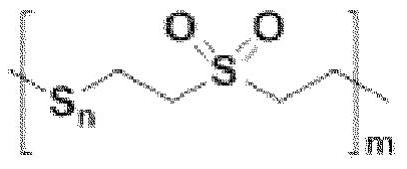

[0082]Then, 85 mg of polyvinylpyrrolidon...

Embodiment 1

[0087] The following 1g episulfide compound 70A, 0.024g sulfur-containing organic particle A prepared in the preparation example, 0.123g reducing agent triphenylphosphine (PPh 3 ) and 0.05 g of a dispersant cetyltrimethylammonium bromide (CTAB) were mixed, and then the mixed solution was filtered using a glass filter with a pore size of 1 μm. Then, place a slide glass with a thickness of 1mm on each side of the LCD glass with a width of 10cm and a height of 10cm, and apply about 5g of the above mixed solution on the center of the LCD glass, and then cover it with another LCD glass , thus preparing the mold. It was put into an oven, and the curing reaction was performed at about 60°C for about 10 hours, and at about 90°C for about 4 hours. After taking out from the oven, the LCD glass was removed to obtain a plastic sample as a flat optical member. The thickness of the plastic sample was about 1 mm when measured using a thickness gauge (model: ID-C112XBS) manufactured by Mitu...

Embodiment 2 to 5 and comparative example 1

[0090] A curable composition and its cured product, and a plastic sample were prepared by the same method as in Example 1, except that the episulfide compound, sulfur-containing organic particles A, reducing agent, dispersant, and catalyst were described in Table 1 below Content used. Meanwhile, 70B used in Comparative Example 1 was as follows.

[0091]

[0092] [Table 1]

[0093] (unit: g) 70A 70B Sulfur-containing organic particles A PPh 3

TCEP CTAB SDS DCA Example 1 1.000 - 0.024 0.123 - 0.050 - - Example 2 1.000 - 0.024 0.123 0.050 - 0.050 - Example 3 1.000 - 0.050 - 0.050 0.020 - 0.011 Example 4 1.000 - 0.100 - 0.050 0.020 - 0.021 Example 5 1.000 - 0.200 - 0.050 0.020 - 0.031 Comparative example 1 0.900 0.100 - - - - - -

[0094] -TCEP: reducing agent, tris(2-carboxyethyl)phosphine

[0095] -SDS: Dispersant, sodium dodecyl sulfate

[0096] -DCA: catalyst, di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com