Positive electrode solid solution material precursor, preparation method and application thereof

A precursor and cathode technology, applied in the field of cathode solid solution material precursor and its preparation, can solve the problems of low electrical conductivity, poor thermal stability, low electronic conductivity, etc., and achieve excellent performance and good structural stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

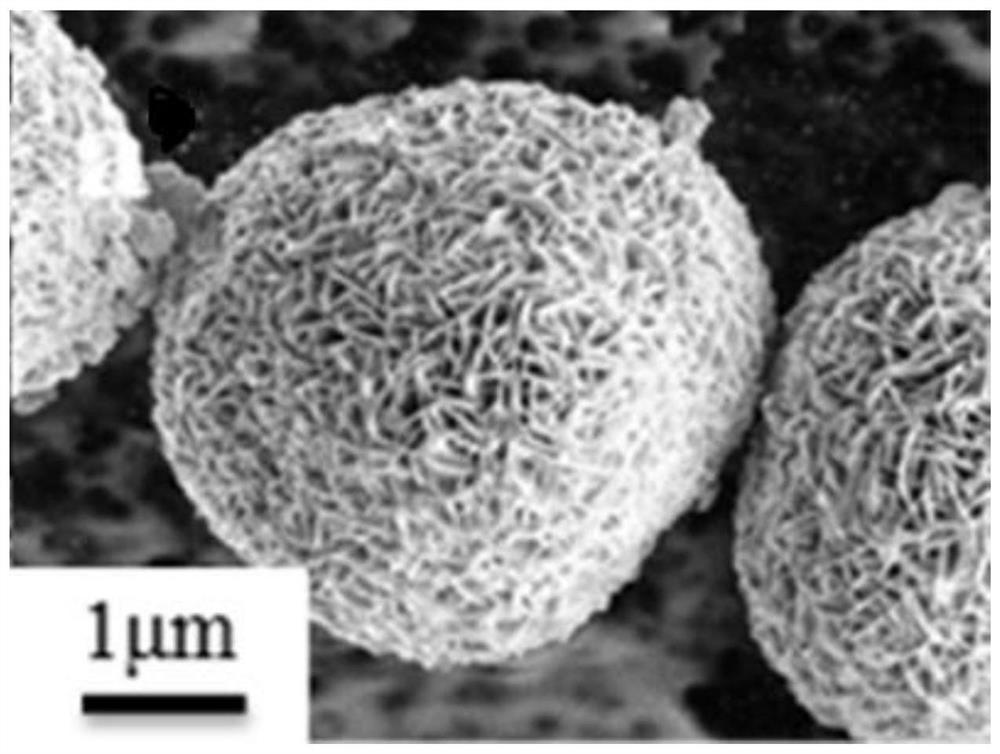

[0047] This embodiment provides a positive electrode solid solution material precursor, characterized in that the preparation method of the positive electrode solid solution material precursor is as follows:

[0048] (1) nickel sulfate, cobalt sulfate, manganese sulfate, zinc sulfate, magnesium sulfate, chromium sulfate are dissolved in deionized water, and solution A is prepared;

[0049] (2) Dissolve tin sulfate and aluminum sulfate in 10L of 0.5M IDS solution, prepare solution B, and prepare 10L of a complexing agent with a concentration of 0.4M, that is, ammonia solution, and add 0.02M sodium tungstate as a tungsten source to obtain Solution C;

[0050] (3) Add 5L of deionized water to the 30L reactor, and add 200mL of 25% concentrated ammonia water as the bottom liquid, adjust the pH to 11, maintain the temperature at 50°C, and feed nitrogen into the reactor for 4 hours to maintain its inert gas environment, inject the prepared solution A, solution B and solution C into ...

Embodiment 2

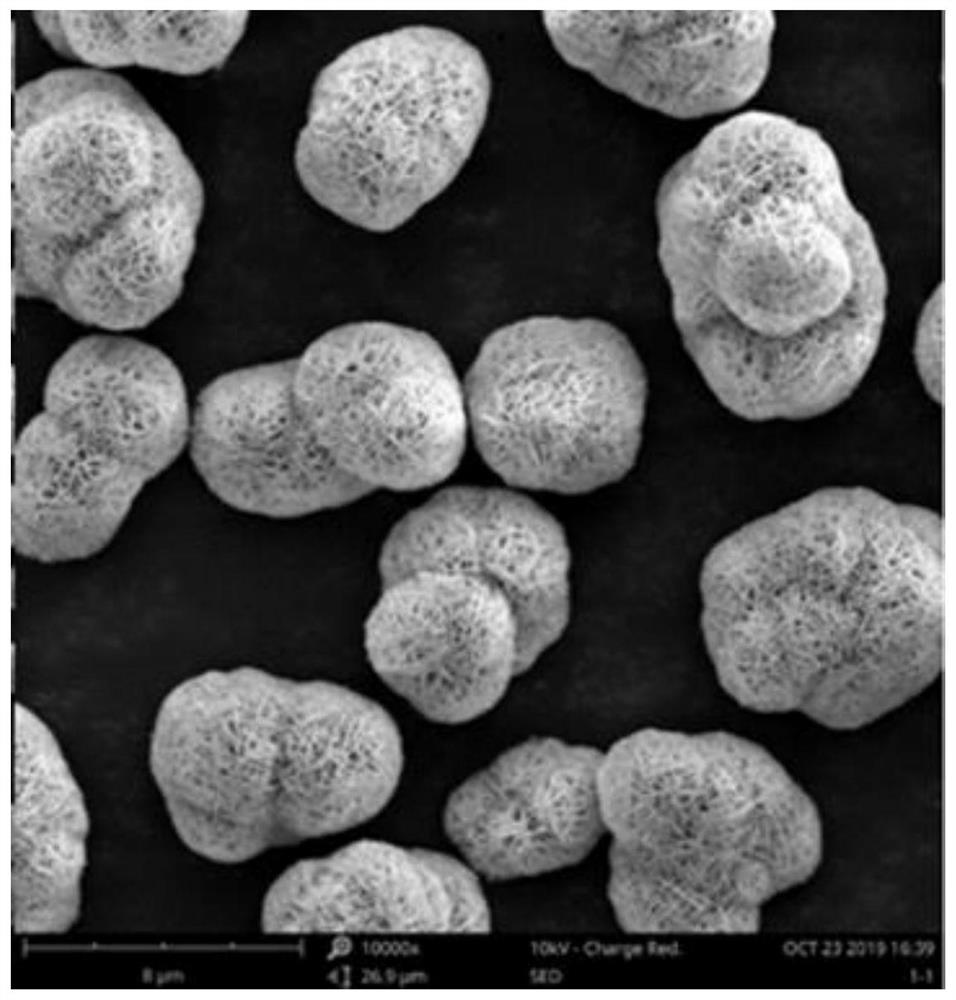

[0052] This embodiment provides a positive electrode solid solution material precursor, characterized in that the preparation method of the positive electrode solid solution material precursor is as follows:

[0053] (1) nickel sulfate, cobalt sulfate, manganese sulfate, magnesium sulfate, chromium sulfate are dissolved in deionized water to prepare solution A;

[0054] (2) Dissolve aluminum sulfate and zirconium sulfate in 10L of 0.5M IDS solution, prepare solution B, and prepare 10L of a complexing agent with a concentration of 0.4M, that is, ammonia solution, and add 0.02M sodium tungstate as a tungsten source to obtain Solution C;

[0055] (3)) 5L of deionized water was added to the 30L reaction kettle, and 200mL of 25% concentrated ammonia water was added therein as the bottom liquid, the pH was adjusted to 11, the temperature was maintained at 50°C, and nitrogen gas was introduced into the reaction kettle for 4 hours to maintain its In an inert gas environment, inject t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com